Edge Milling Machine

Our edge milling machine features a high speed and is highly efficient, allowing it to generate excellent flatness on a work piece’s surface. It is the first choice for angle heel milling on angle steel in the tower industry.

Features

When compared to conventional planning machines, our edge milling machine is more convenient and flexible.

With a high level of automation, our CNC processing equipment can effectively reduce labor intensity. It can also work with unlimited lengths in work pieces and features an improved working efficiency.

With flexible adjustments and stable operations, this CNC milling machine is easy to operate, which decreases the requirements for manual operation.

Specifications

1. Power supply: Three-phase AC380V 50Hz

2. Power: 15kw

3. Dimension: approximately 2,650mm×1,850mm×1,750mm

4. Rotary speed of principal axis: 450 r/min

5. Quantity of principal axis: 3

6. Automatic feeding speed: From100 mm/min to 500mm/min (automatic adjustment)

7. Minimum length of work piece: 350mm

8. Maximum dimension of angle steel: L250×32

Working Process

You can use the touch screen to directly enter the requested depth. After the blade control button is pressed, the cutter will automatically fit to the cutting position. Our steel milling machine will automatically figure out the cutting speed according to the pre-set parameters.

Place the angle steel on the edge milling machine.

Press the cycle start button, setting it to automatic mode, and the machine will then work on automatic.

The angle steels with same specifications can be cut successively.

| Angle steel specification | Radius of rounded angle | Depth (the gap is1.5mm) | Suggested cutting tools |

| 63 | R7 | 4.4 | R20 |

| 70 | R8 | 4.8 | R20 |

| 75 | R9 | 5.2 | R20 |

| 80 | R9 | 5.2 | R20 |

| 90 | R10 | 5.6 | R20 |

| 100 | R12 | 6.5 | R20 |

| 110 | R12 | 6.5 | R20 |

| 125 | R14 | 7.3 | R20 |

| 140 | R14 | 7.3 | R20 |

| 160 | R16 | 8.1 | R24 |

| 180 | R16 | 8.1 | R24 |

| 200 | R18 | 9 | R24 |

| 220 | R20 | 9.8 | R28 |

| 250 | R22 | 10.6 | R28 |

| 320 | R28 | 13.1 | R35 |

Links:https://www.globefindpro.com/products/72335.html

-

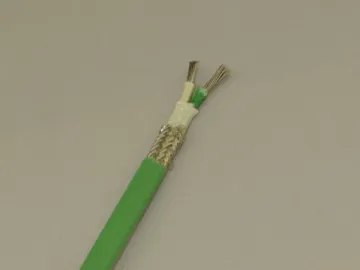

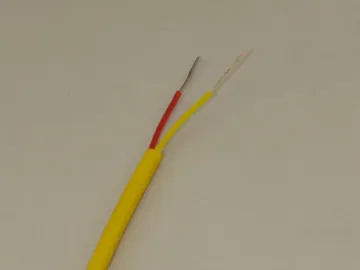

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x7/0.5mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x7/0.5mm)

-

KX Thermocouple Extension Wire(Silicone Rubber Insulated Wire 2X7/0.2mm)

KX Thermocouple Extension Wire(Silicone Rubber Insulated Wire 2X7/0.2mm)

-

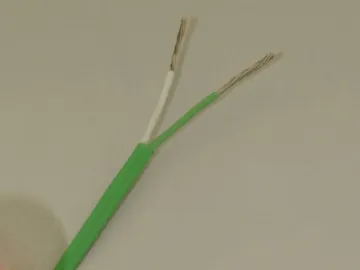

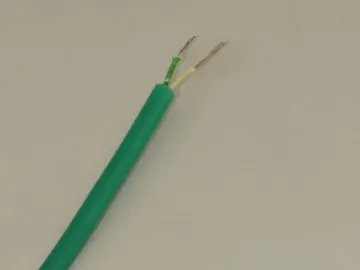

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x19/0.2mm)

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x19/0.2mm)

-

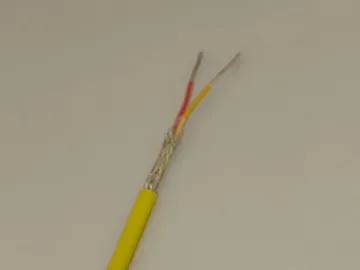

EX Thermocouple Extension Wire

EX Thermocouple Extension Wire

-

KX Thermocouple Extension Wire(Silicone Rubber Sheathed Wire 2x7/0.2mm)

KX Thermocouple Extension Wire(Silicone Rubber Sheathed Wire 2x7/0.2mm)

-

Steel Angle Opening and Closing Machine

Steel Angle Opening and Closing Machine

-

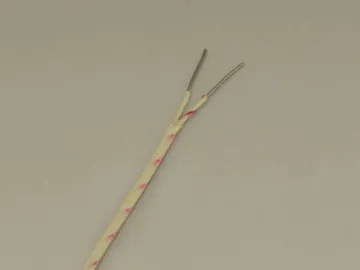

JX Thermocouple Extension Wire(IEC Color Coded Fiberglass Insulated Wire 2x7/0.2mm)

JX Thermocouple Extension Wire(IEC Color Coded Fiberglass Insulated Wire 2x7/0.2mm)

-

TPP103 / TPP104 CNC Plate Punching Machine

TPP103 / TPP104 CNC Plate Punching Machine

-

KX Thermocouple Extension Wire(Fiberglass Insulated Silicone Rubber Sheathed Wire 2X7/0.2mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Silicone Rubber Sheathed Wire 2X7/0.2mm)

-

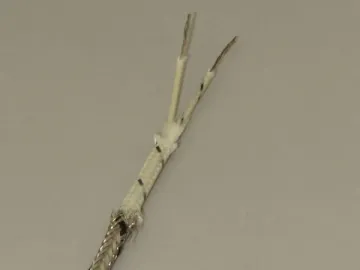

Thermocouple Extension Wire(Vitreous Silica Insulated Wire 2x1/0.81mm)

Thermocouple Extension Wire(Vitreous Silica Insulated Wire 2x1/0.81mm)

-

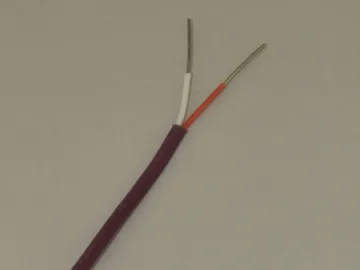

SX Thermocouple Extension Wire

SX Thermocouple Extension Wire

-

CNC Hot Bending Machine

CNC Hot Bending Machine