TPPD103 / TPPD104 CNC Punching Drilling Machine

Our CNC punching drilling machine for plates is equipped with a principle computer, X and Y axis workbench, hydraulic system, electric control system, punching unit, drilling unit and marking unit.

This CNC machining equipment for plates can be excellently used for the punching, drilling and marking of the junction plates in tower and sheet metal processing industries.

Features

1. The drilling unit has a variety of functions. It can perform a fast forward noncutting stroke, low speed feeding and a high speed return stroke, all of which effectively improve the working efficiency.

2. When programming this equipment, you need only enter work piece information, such as the bore diameter, stadia, and quantity. You can also use CAD/CAM to convert data directly.

3. It comes equipped with a self-diagnostic function to seek out faults.

4. Our CNC processing equipment’s X and Y axes are both equipped with a servo motor, ball screw and linear guideway, which helps enable our CNC punching drilling machine to have better precision, more stable operation, and a longer service life.

5. The body of this CNC drilling machine is composed of C-shaped welded steel plates, all of which feature excellent rigidity, wider working space and a longer service life.

6. Our CNC punching machine has three dye stations, one of which is used for marking the character, and all three dye stations can have an automatic switchover.

7. We adopt advanced CNC technology and servo motor controlled feeding system in order to ensure our plate processing equipment has higher efficiency and can generate work pieces with better accuracy.

8. With the main parts constructed in a modular assembly, our CNC punching drilling machine requires little to no maintenance.

9. Punching, drilling and marking can all be carried out on the same plate.

10. As the workbench is a stainless steel plate, the appearance is more appealing and practical.

Parameters of CNC Punching Drilling Machine| Model | TPPD103 | TPPD104 | |

| Max. dimension of workpiece (L×W)(mm) | 1,500×800 | 1,500×1,000 | |

| Max. punching diameter (mm) | Φ26 | ||

| Thickness of punched-plate (mm) | From 5 to 25(Q235) | ||

| Max. drilling diameter (mm) | Φ50 | ||

| Max. thickness of drilled-plate(mm) | 40 | ||

| Punching force (kn) | 1,000 | ||

| Marking force (kn) | 800 | ||

| Min. distance between hole and plate's edge (mm) | Punching | 25 | |

| Drilling | Depending on the hole diameter | ||

| Dimension of character (mm) | 14×10×19(According to customer's requirement) | ||

| Number of character | 12 | ||

| Number of die station | 4 | ||

| Feeding speed of drilling head (mm/min) | From 25 to 280 | ||

| Stroke of drilling spindle (mm) | 180 | ||

| Rotation speed of drilling spindle(r/min) | From 120 to 560 | ||

| Processing precision | In accordance with GB2694 | ||

| Programming mode | Keyboard input, RS232 interface, floppy disk and USB interface | ||

| Dimension (L×W×H) (mm) | 32,00×3,000×2,600 | 3,500×3,000×2,600 | |

| Weight (kg) | Appr. 5,800 | Appr. 6,200 | |

Links:https://www.globefindpro.com/products/72345.html

-

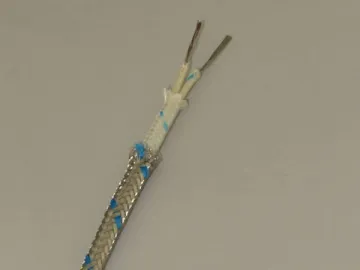

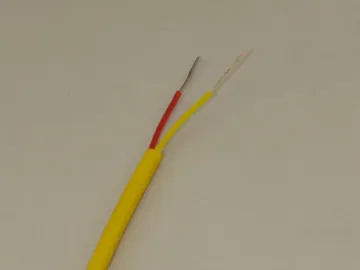

KX Thermocouple Extension Wire(ANSI Color Coded Wire 2x7/0.2mm)

KX Thermocouple Extension Wire(ANSI Color Coded Wire 2x7/0.2mm)

-

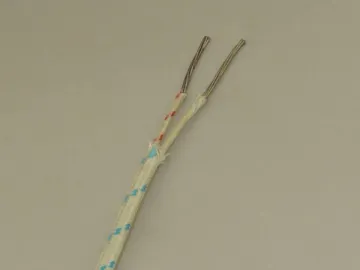

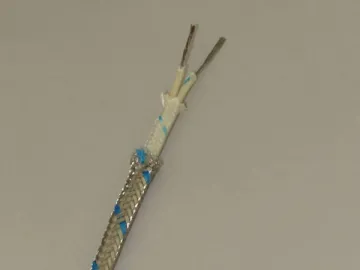

JX Thermocouple Extension Wire(DIN Color Coded Fiberglass Insulated Wire 2x7/0.2mm)

JX Thermocouple Extension Wire(DIN Color Coded Fiberglass Insulated Wire 2x7/0.2mm)

-

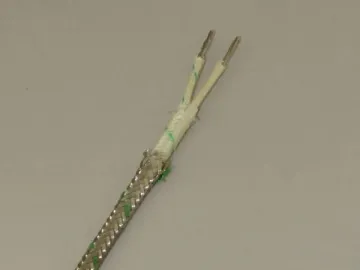

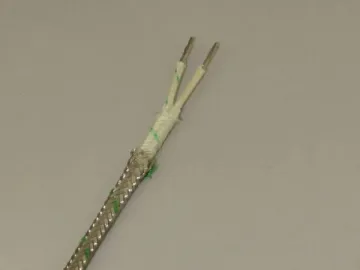

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x4/0.65mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x4/0.65mm)

-

KX Thermocouple Extension Wire(PFA Insulated Wire 2x0.25mm)

KX Thermocouple Extension Wire(PFA Insulated Wire 2x0.25mm)

-

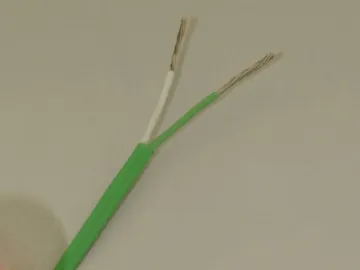

KX Thermocouple Extension Wire(IEC Color Coded Wire 2x7/0.2mm)

KX Thermocouple Extension Wire(IEC Color Coded Wire 2x7/0.2mm)

-

CNC Plasma and Flame Cutting Machine

CNC Plasma and Flame Cutting Machine

-

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x7/0.3mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x7/0.3mm)

-

JX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x14/0.2mm)

JX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x14/0.2mm)

-

Steel Angle Opening and Closing Machine

Steel Angle Opening and Closing Machine

-

KX Thermocouple Extension Wire(Silicone Rubber Sheathed Wire 2x7/0.2mm)

KX Thermocouple Extension Wire(Silicone Rubber Sheathed Wire 2x7/0.2mm)

-

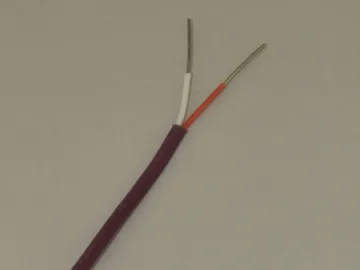

EX Thermocouple Extension Wire

EX Thermocouple Extension Wire

-

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x19/0.2mm)

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x19/0.2mm)