Resistance Heating Wire

Our resistance heating wire is available in different models which are made of different materials, such as pure nickel, chromel alloy, Fe-Cr-Al alloy and copper nickel alloy. During the production, it was treated by a range of processes like smelting, steel rolling, forging, annealing, drawing, surface treatment, resistance control test, etc. It now has been widely used for making heating equipment like industrial furnace, household heating appliance, various electrical resistors (like locomotive braking resistor), and so on.

Brief Introduction of Resistance Heating Wire

Product name: heating resistance wire

Type: Ni-Cr wire, pure nickel, chromel alloy, Fe-Cr-Al alloy, fopper nickel alloy, etc.

Color: bright, oxidized

Package: carton or wooden case as demanded

Application: making heating equipment like industrial furnace, civil heating appliance, various electrical resistors and locomotive braking resistor

Place of Origin: Jiangsu, China (Mainland)

Eco-friendly: Yes

MOQ: 30kgs

Certificate: ISO, CQC

Making sample time: All types are in stock.

Trade term: FOB, EXW, CIF, or CFR

Forms and Specifications of Resistance Heating Wire

Round type diameter: 0.02-12mm

Max. width of ribbon/strip type: 300mm

Stranded type: according to your requests

Properties: annealed, oxidized/acid treated/bright

Specifications of Cold-drawing Round Type Resistance Heating Wire

| Diameter (mm) | Tolerance (mm) | Diameter (mm) | Tolerance (mm) |

| 0.03-0.05 | ±0.005 | >0.50-1.00 | ±0.02 |

| >0.05-0.10 | ±0.006 | >1.00-3.00 | ±0.03 |

| >0.10-0.20 | ±0.008 | >3.00-6.00 | ±0.04 |

| >0.20-0.30 | ±0.010 | >6.00-8.00 | ±0.05 |

| >0.30-0.50 | ±0.015 | >8.00-12.0 | ±0.4 |

Specification of Cold-drawing Strip Type Resistance Heating Wire

| Thickness (mm) | Tolerance (mm) | Width (mm) | Tolerance (mm) |

| 0.05-0.10 | ±0.010 | 5.00-10.0 | ±0.2 |

| >0.10-0.20 | ±0.015 | >10.0-20.0 | ±0.2 |

| >0.20-0.50 | ±0.020 | >20.0-30.0 | ±0.2 |

| >0.50-1.00 | ±0.030 | >30.0-50.0 | ±0.3 |

| >1.00-1.80 | ±0.040 | >50.0-90.0 | ±0.3 |

| >1.80-2.50 | ±0.050 | >90.0-120.0 | ±0.5 |

| >2.50-3.50 | ±0.060 | >120.0-250.0 | ±0.6 |

Chemical Composition of Resistance Heating Wire

| Alloy material | Chemical composition (%) | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | others | |

| Max. (≤) | ||||||||||

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.60 | 20.0-23.0 | Rest | ≤0.50 | ≤1.0 | - |

| Cr30Ni70 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.60 | 28.0-31.0 | Rest | ≤0.50 | ≤1.0 | - |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.60 | 15.0-17.0 | 55.0-61.0 | ≤0.50 | Rest | - |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1 | 1.00-3.00 | 18.0-21.0 | 34.5-36.0 | - | Rest | - |

| Cr20Ni30 | 0.08 | 0.02 | 0.015 | 1 | 1.00-2.00 | 18.0-21.0 | 30.0-31.5 | - | Rest | - |

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | - | 3.5-4.5 | Rest | - |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | - | 4.5-5.3 | Rest | - |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | Rest | - |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | Rest | - |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | Rest | - |

| 1Cr20Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | Rest | - |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | Rest | Nb add 0.5 |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | Rest | Mo add 2.0 |

Technical Specification of Resistance Heating Wire (Part 1)

| Alloy type | Diameter (mm) | Resistivity (μΩm, 20℃) | Tensile strength (N/mm²) | Elongation (%) | Bending times | Max. continuous service temperature (℃) | Service life (hours) |

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥ 0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥ 0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

Technical Specification of Resistance Heating Wire (Part 2)

| Alloy type | Chemical composition (%) | Density (g/cm³) | Melting point (℃) | Resistivity (μΩm, 20℃) | Tensile strength (N/㎜²) | Elongation (%) | Max. continuous service temperature (℃) | ||||||

| Cu | Mn | Ni | Cr | Al | Fe | ||||||||

| Constantan (Cu-Ni Alloy) | CuNi44 | Rest | 1.0 | 44 | - | - | - | 8.9 | 1280 | 0.49 | ≥400 | ≥20 | 450-700 |

| CuNi40 | Rest | 1.0 | 40 | - | - | - | 8.9 | 1280 | 0.48±0.03 | ≥400 | ≥20 | 450-700 | |

| CuNi34 | Rest | 1.0 | 34 | - | - | - | 8.9 | 1180 | 0.40 | ≥400 | ≥20 | 350-600 | |

| CuNi30 | Rest | 1.0 | 30 | - | - | - | 8.9 | 1170 | 0.35 | ≥400 | ≥20 | 350-600 | |

| CuNi23 | Rest | 0.5 | 23 | - | - | - | 8.9 | 1150 | 0.30 | ≥350 | ≥20 | 300-450 | |

| CuNi19 | Rest | 0.5 | 19 | - | - | - | 8.9 | 1135 | 0.25 | ≥340 | ≥20 | 300-450 | |

| CuNi15 | Rest | 0.3 | 14.5 | - | - | - | 8.9 | 1115 | 0.20 | ≥310 | ≥20 | 300-400 | |

| CuNi10 | Rest | - | 10 | - | - | - | 8.9 | 1100 | 0.15 | ≥290 | ≥20 | 250-350 | |

| CuNi8 | Rest | - | 8 | - | - | - | 8.9 | 1097 | 0.12 | ≥270 | ≥20 | 250-350 | |

| CuNi6 | Rest | - | 6 | - | - | - | 8.9 | 1095 | 0.10 | ≥251 | ≥18 | 200-300 | |

| CuNi2 | Rest | - | 2 | - | - | - | 8.9 | 1090 | 0.05 | ≥220 | ≥18 | 200-300 | |

| CuNi1 | Rest | - | 1 | - | - | - | 8.9 | 1085 | 0.03 | ≥210 | ≥18 | 200-300 | |

| Karma | - | - | Rest | 19-22 | 2.5-3.2 | 2-3 | 8.1 | 1400 | 1.33±0.07 | 950 | 10-20 | -60-300 | |

| Evanohm | - | - | Rest | 19-22 | 2.5-3.2 | 1.0 | 8.4 | 1400 | 1.05±0.05 | 686-736 | 30 | 0-500 | |

| Manganin (Cu-Mn Alloy) | CuMn12 | Rest | 11-13 | 2-3 | - | - | - | 8.4 | 960 | 0.47±0.03 | 490-539 | 10-30 | 50 |

| CuMn13 | Rest | 11-13 | - | - | - | - | 8.4 | 960 | 0.44±0.04 | 490-539 | 10-30 | 80 | |

| CuMn8 | Rest | 8-10 | 2-5 | - | - | - | 8.7 | 960 | 0.35±0.05 | 490-539 | 10-30 | 80 | |

Process Flow

Packaging and Delivery of Resistance Heating Wire

Advantage of Our Resistance Heating Wire

1. Low MOQ: The order can meet your promotional business very well.

2. OEM accepted: We can produce various kinds of resistance wire as per your design if you provide us the related drawings.

3. Good service: MICC treats clients as friend, and the service will be excellent.

4. Good quality: We have a strict quality control system and good reputation on the overseas market.

5. Fast and cheap delivery: We are granted with big discount by the carriers due to our long-term contracts with them.

Order Guide of Resistance Heating Wire

General Order Information

As a senior resistance heating cable supplier, MICC has more than 5 years of experience and sound reputation and credits among the foreign customers for our first-rate products and services. Our distribution network has expanded to Europe, South America, the Middle East, etc. OEM orders are especially welcomed!

In addition, we assure you that every order could be delivered on time.

Procedure of Placing an Order of Resistance Heating Wire

1. The inquiry will get professional and accurate quotation.

2. Confirm the price, trade terms, lead time, artwork, payment terms, etc.

3. MICC sends the proforma invoice with MICC seal.

4. Customer arranges the payment of deposit and sends us bank slip.

5. We inform the clients that we have got the payment, and will make the samples according to your requests. Then we will send you product photos or real samples to get your approval. After your approval, we will arrange the production and inform you the estimated time.

6. In the middle of the production, we send you more photos of the production line in which you can see your products. The estimated delivery time will be reconfirmed.

7. At the end of volume production, product photos will be sent to customers again.

8. Clients make payment for balance. MICC ships the goods and informs you the tracking number and check the status of shipment for clients.

9. The order is finished perfectly when you receive the goods and get satisfied with them.

10. We are grateful for any feedbacks to MICC about quality, service, market feedback and suggestions, so that we can keep improving.

Links:https://www.globefindpro.com/products/72381.html

-

Ceramic Thermocouple Insulator

Ceramic Thermocouple Insulator

-

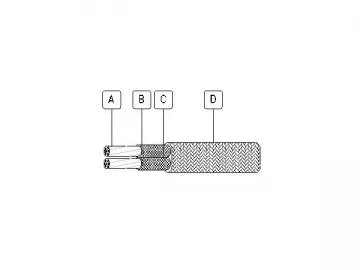

RTD Extension Wire(Teflon Insulated Wire 3x7/0.16mm)

RTD Extension Wire(Teflon Insulated Wire 3x7/0.16mm)

-

Thermocouple Connectors

Thermocouple Connectors

-

High Capacity Pellet Mill

High Capacity Pellet Mill

-

Pellet Cooler with Slide Valve Reciprocating Discharge Mechanism

Pellet Cooler with Slide Valve Reciprocating Discharge Mechanism

-

Three-Roll Crumbler

Three-Roll Crumbler

-

Silicon Nitride Thermocouple Protection Tube

Silicon Nitride Thermocouple Protection Tube

-

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x7/0.5mm)

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x7/0.5mm)

-

RTD Extension Wire(Teflon Insulated Wire 4x7/0.2mm)

RTD Extension Wire(Teflon Insulated Wire 4x7/0.2mm)

-

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x7/0.2mm)

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x7/0.2mm)

-

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x7/0.2mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x7/0.2mm)

-

RTD Extension Wire(Fiberglass Insulated Wire 3x7/0.15mm)

RTD Extension Wire(Fiberglass Insulated Wire 3x7/0.15mm)