PU Timing Belts

Manufactured using imported thermoplastic polyurethane material, our PU timing belts have excellent wear resistance. The internal framework of the belts is made up of steel wire and Kevlar fiber. Our polyurethane timing belts maintain excellent running ability and allow for very small tolerance during transmission.

We add a layer of nylon to the tooth surface/ back of tooth in the production process to guarantee our industrial timing belts have the wear resistance to maintain constant running in particular applications. Also, with the thickened polyurethane layer on the back of the teeth, our PU timing belts are capable of preventing corrosion and handling high loads.

Our PU synchronous belts have a wide range of applications and are especially suitable for industries requiring high precision, high torque, linear drive, as well as positive and negative shifting.

Materials of PU Timing Belts

1. Polyurethane (PU)

2. Steel wire rope or Kevlar fiber framework

3. Nylon canvas on the tooth surface

Features of PU Timing Belts

1. We provide closed-loop PU timing belts, open ended PU timing belts and double sided PU timing belts.

2. Our durable PU driving belts have excellent resistance to oil, abrasion, water and chemicals.

3. Our PU timing belts have superior strength and hardness and are suitable for high power applications.

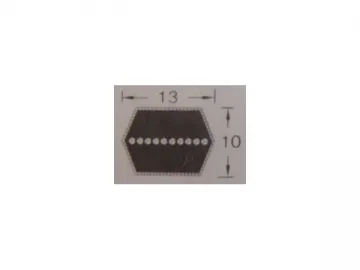

Models and Specifications of PU Timing Belts

| Models | Tooth Pitch (mm) | Depth of Tooth (mm) | Thickness of Belt (mm) | Material | Standard Width (mm) | Length (mm) |

| T2.5 | 2.5 | 0.7 | 1.3 | Polyurethane | 6/10/12 16/20/25 32/50/75 | 120- 3,640 |

| T5 | 5 | 1.2 | 2.2 | |||

| T10 | 10 | 2.5 | 4.5 | |||

| AT5 | 5 | 2.7 | 2.5 | Polyurethane | 6/10/12 16/20 | 225-1,860 |

| AT10 | 10 | 4.5 | 5 | |||

| T5DL | 5 | 2.2 | 1.8 | Polyurethane | 6/10/12 16/20 | 410-1,880 |

| T10DL | 10 | 4.5 | 3.5 |

Links:https://www.globefindpro.com/products/72489.html