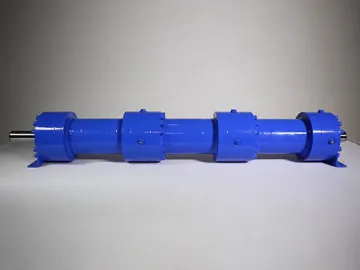

Cold Drawing Machine

A cold drawing machine is designed for the deep processing of metal materials. With an advanced design and compact structure, this cold drawing bench is highly precise, efficient and reliable. Its semi-automatic process means it is easy to operate and maintain and has a low error rate.

This tube drawing machine can process bars and tubes made of black metal and non-ferrous metal at normal room temperatures and can process such shaped pieces as square and hexagonal steel pieces. The cold draw bench is an essential machine in steel plants, steel pipe plants and standard component factories. It is increasingly used in the productions of hydraulic cylinder tubes, pneumatic cylinder tubes, gasoline pipes and other precision cold drawn pipes.

Features of Cold Drawing Machine

1) This cold drawing machine ensures high concentricity of the cold drawn steel tubes.

Since the hydraulic transmission is quite smooth, the line of drawing force, the steel pipe axes, and the core rod perfectly align with each other. As a result, radial run-outs are avoided and the cold drawn tubes (the finished products) are precision-made and straight with high concentricity.

2) With a streamlined structure, this hydraulic cold-drawing machine is quite easy to operate.

All parts of this tube processing machine are simplified so it is easy and efficient to process metal tubes. Its chassis has a pre-stressed frame which increases the machine’s mechanical strength, rigidity and carrying capacity.

3) This cold drawing machine only needs a simple foundation.

This tube processing equipment is equipped with strong cylinder bases, die bases and tailstocks, all of which are supported by eight stay tubes and integrated by four rod assemblies. As the machine is loaded, the drawing force is blocked within the frame so there is no additional pressure on the foundation. This machine only needs a simple foundation that can bear the weight of the machine, which is more cost-effective.

4) This cold draw bench has stepless speed adjustment.

The hydraulic system of this tube processing machine is equipped with cartridge valves and manifold, so the drawing speed can be regulated smoothly and continuously, even at large scale. The stepless speed adjustment makes the machine easy and convenient to operate.

Basic Specifications of Cold Drawing Machine

Product Series: GL1500 and GL1600;

Extended Length: 6-1600m ;

Maximum Outer Diameter of Cold Drawn Tube: Φ159- 426.

| Model | GL1500 | GL2000 | GL2500 | GL3000 | GL3500 | GL4000 | GL5000 | GL6300 |

| Rated Power | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 5000 | 6300 |

| Tube Length | 6~10 | 6~12 | 8~14 | 10~14 | 10~14 | 10~14 | 12~16 | 12~16 |

| Rated Working Pressure of Spindle Cylinder | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 26 |

| Pump Flow Rate(ML/RMP) | 160 | 160 | 160/250 | 160/250 | 160/250 | 250 | 250 | 250 |

| Speed of Cold Drawing Operation | 2.5~7 | 2~6 | 2~6 | 2~6 | 2~6 | 2~6 | 1.5~4.5 | 1~4 |

| Engines | 2~3 | 2~4 | 2~4 | 2.5~4 | 2.5~4 | 2.5~4 | 3~5 | 3~5 |

| Working Pressure of Auxiliary System | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 12 |

| Flow of Auxiliary System(L) | 56 | 56 | 56 | 56 | 56-100 | 56-100 | 100-145 | 100-145 |

| Working Power (kW) | 121-176 | 121-176 | 165-240 | 195-285 | 242-352 | 286-418 | 286-418 | 286-418 |

| The above data are only for reference. Technical specifications of our productscomply with the contracts, according to each customer’s requirements. | ||||||||

Links:https://www.globefindpro.com/products/72500.html