Raw Edge V-Belts

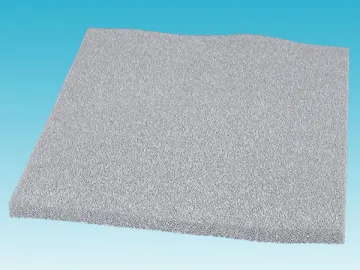

For the production of our raw edge V-belts we have adopted a high quality Japanese synthetic chloroprene rubber (CR). We have also add many rubber auxiliary materials to our cut edge V-belt for different purposes, for instance, premium polyester tension wire is used to strengthen the internal framework of the belt; and a blend of fibers are applied to the back for further protection.

When compared to wrapped V-belts, our raw edge V-belts have teeth at the bottom and can reduce the accumulation of heat or stress concentration, which can help to extend the service life of our transmission belts. Our cogged V-belt only has very little tolerance for movement when used in high-speed transmission.

Design Features of Raw Edge V-Belts

1. Raw edge, molded and cogged

2. Fiber-filled base

3. Polyester tension wire

Product Features of Raw Edge V-Belts

1. Our industrial V-belts can adapt to high power rating and small pulley diameters.

2. Having good abrasion resistance and skid resistance, our raw edge V-belt runs smoothly and reliably.

3. Our maintenance-free moulded cogged V-belt has excellent tensile strength and low drawing force.

Models and Specifications of Raw Edge V-Belts

| Classical V-Belt | Narrow V-Belt | ||||

| DIN2215 | DIN7753 | USA-Standard | |||

| Section | Dimension (mm) (W×H) (Appr.) | Section | Dimension (mm) (W×H) (Appr.) | Section | Dimension (mm) (W×H) (Appr.) |

| ZX/X10 | 10×6 | XPZ | 9.7× 8 | 3VX | 9×8 |

| AX/X13 | 13×8 | XPA | 12.7×10 | 5VX | 15×13 |

| BX/X17 | 17×11 | XPB | 16.3×13 | ||

| CX/X22 | 22×14 | XPC | 22×18 | ||

| DX/X32 | 32×20 | ||||

Links:https://www.globefindpro.com/products/72512.html