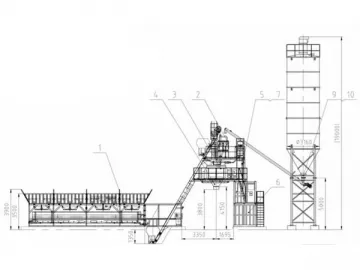

Mobile Batch Asphalt Mixing Plant

QLB-30/QLB40 Mobile batch asphalt mixing plant

QLB-8/QLB-15S/QLB-15D Mobile batch asphalt mixing plant QLB-20 Mobile batch asphalt mixing plant

Advantages

1. In our mobile batch asphalt mixing plant, the working status of the dust collecting system is demonstrated by negative parameters, in which the air flow can be adjusted to perfectly match the burning system.

2. An air cylinder is used for controlling the outlet of the batching hopper. The aggregate in our mobile asphalt plant is measured from large to small in order to improve the precision of our weighing system. The weighing system is controlled by a computer, so it is easy to adjust to suit your needs.

3. The raw material transfer for the mobile batch asphalt mixing plant is achieved by a tilting belt with an inertia feeding method, which makes the entire conveying process steady and reliable.

4. Coal powder is the fuel for the burning system in this asphalt batch mixing plant, which increases the combustion efficiency, and lowers the cost.

5. The drying roller of the mobile batch asphalt mixing plant is driven by the gears, leading to a steady operation.

6. We use rollers for the mixing process of this asphalt mixing equipment, and it is highly efficient.

7. A bucket elevator is adopted for the material storage system, while the air cylinder is in charge of controlling the door.

8. The control system of the mobile batch asphalt mixing plant can monitor the key processes such as the material weighing system in real time.

| Type | QLB-8 | QLB-15S | QLB-15D | QLB-20D | QLB-40 |

| Feature | The equipment comes with modular design and intermittent production process, and is movable and easy to assemble and disassemble. | ||||

| Production capacity | 8ton/h | 15ton/h | 15-20ton/h | 15-20ton/h | 40ont/h |

| Mixing capability | 400kg/batch | 500kg/batch | 400kg/batch | 1500kg/batch | 1800kg/batch |

| Work cycle | 3min | 3min | 3min | 3min | |

| Control method | Manual/automatic/semi-automatic | ||||

| Installed capacity | ~13kW | ~70kW | ~60kW | ~90kW | 100kW |

Links:https://www.globefindpro.com/products/72759.html

-

Concrete Mixer Truck

Concrete Mixer Truck

-

Bar Table

Bar Table

-

Meeting Room Chair

Meeting Room Chair

-

Stationary Concrete Batching Plant with Bucket Elevator Feeding

Stationary Concrete Batching Plant with Bucket Elevator Feeding

-

Ergonomic Executive Chair

Ergonomic Executive Chair

-

Planetary Concrete Mixer

Planetary Concrete Mixer

-

Batch Asphalt Mixing Plant

Batch Asphalt Mixing Plant

-

Ready-Mix Concrete Batching Plant

Ready-Mix Concrete Batching Plant

-

Stationary Concrete Batching Plant with Belt Conveyor Feeding

Stationary Concrete Batching Plant with Belt Conveyor Feeding

-

Foundation-Free Concrete Batching Plant

Foundation-Free Concrete Batching Plant

-

Manager Chair (with Alloy Frame)

Manager Chair (with Alloy Frame)

-

High Back Executive Chair

High Back Executive Chair