Black Silicon Carbide Abrasive

Product Number: SC-SIC

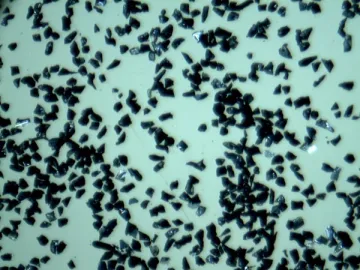

The main raw materials of the black silicon carbide abrasive include quartz sand, petroleum coke and quality silica. The black silicon carbide abrasive is made by means of smelting in high-temperature resistance furnace, possessing good hardness (between corundum and diamond), higher mechanical strength than corundum, crisp and sharp characteristics.

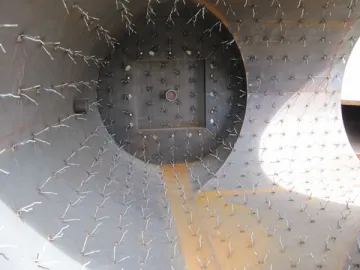

The artificial abrasive is extensively applicable for abrasive tool, electronic product cutting and grinding, refractory material, special ceramics, foamed ceramics, modifying agent for coating, plastic and rubber, military and aviation industry, steelmaking desoxidant, etc.

Technical Indicators of Black Silicon Carbide Abrasive

| Grit | SiC | F.C. | Fe2O3 |

| F12-F90 | 98.50%min | 0.20%max | 0.60%max |

| F100-150 | 98.00%min | 0.30%max | 0.80%max |

| F180-220 | 97.00%min | 0.30%max | 1.20%max |

| F230-F400 | 96.00%min | 0.40%max | 1.20%max |

| F500-F800 | 95.00%min | 0.40%max | 1.20%max |

| F1000-F1200 | 93.00%min | 0.50%max | 1.20%max |

| P12-P90 | 98.00%min | 0.25%max | 0.70%max |

| P100-P150 | 97.5%min | 0.35%max | 0.90%max |

| P180-P220 | 96.00%min | 0.35%max | 1.35%max |

| P230-P500 | 95.50%min | 0.40%max | 1.35%max |

| P600-P1500 | 95.00%min | 0.40%max | 1.35%max |

| P2000-P2500 | 93.00%min | 0.50%max | 1.35%max |

Grain Size Distribution: According to FEPA-Standard 42-GB-1984 R1993

Bulk Density Index (g/ cm3)

| Grit No. | F12 | F16 | F20 | F24 | F30 | F36 | F46 |

| B.D. | 1.45-1.59 | 1.44-1.58 | 1.44-1.58 | 1.43-1.57 | 1.43-1.57 | 1.41-1.55 | 1.39-1.53 |

| Grit No. | F60 | F80 | F100 | F120 | F150 | F180 | F220 |

| B.D. | 1.37-1.51 | 1.36-1.50 | 1.35-1.49 | 1.33-1.47 | 1.31-1.45 | 1.30-1.44 | 1.30-1.44 |

Related Names

Artificial Abrasive | Ceramic Abrasive |Grinding Material

Related Products

Links:https://www.globefindpro.com/products/72824.html