Vitrified Bonded Wheels

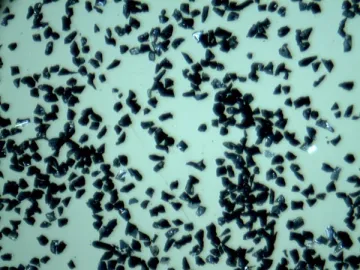

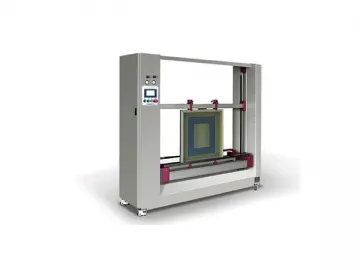

The vitrified bonded wheels are used for grinding, lapping, honing and polishing. The characteristics of a vitrified bonded wheel are determined by type of abrasive grain, grade, bond, structure, shape and dimensions.

With over a decade year experience in abrasive material industry, SHUO CHENG is able to provide you with various reliable vitrified bonded wheels. You can totally depend on us to get your ideal vitrified bonded wheels.

Abrasive Type Selection

| Abrasive type | Abrasive code | Color | Applications |

| Brown fused alumina | A | Brown | Carbon steel, alloy steel, malleable iron, hardened bronze. |

| White fused alumina | WA | White | Alloy steel, high speed steel, high carbon steel, quencher steel, gear grinding and thin walled workpieces. |

| Pink fused alumina | PA | Red | For form grinding, precision grinding of cutters, measuring tools, surface finish grinding. |

| Monocrystallinefused alumina | SA | White Khaki | Suitable for great hardness and toughness material like stainless steel, high vanadium-high speed steel, Ti-alloy, etc. |

| Microcrystalline fused alumina | MA | Brown | For heavy pressure grinding, lens grinding. |

| Black silicon carbide | C | Black | Cast iron, glass, jadeware, non-metal material. |

| Green silicon carbide | GC | Green | Fragile and hard alloy, glass, stone, jadeware |

| Zirconia alumina | ZA | Grey | Heavy pressure grinding. |

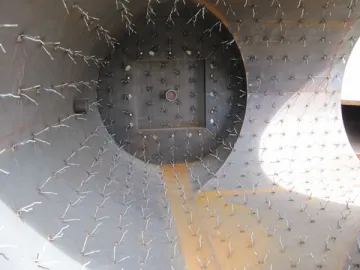

Vitrified Bonded Grinding Wheel Series

| Shape code | Dimensions(mm) | |||

| China GB 84 standard | China GB 94 standard | Diameter(D) | Thickness(T) | Hole diameter(H) |

| P | 1 | 3-1100 | 0.5-400 | 1-480 |

| PH | 1-F | 100-600 | 6-100 | 75-305 |

| PSX1 | 4 | 100-750 | 8-100 | 16-305 |

| PSX2 | 1-N | 500-900 | 25-200 | 203-305 |

| PSX3 | 7-N | 250-900 | 50-300 | 75-305 |

| PDX1 | 1-C | 125-350 | 8-25 | 32-127 |

| PDX2 | 3 | 75-750 | 6-100 | 13-305 |

| PDA | 5 | 10-900 | 10-150 | 3-305 |

| PSA | 7 | 200-1100 | 50-400 | 75-350 |

| N | 2 | 90-600 | 80-150 | W7.5-100 |

| B | 6 | 40-300 | 25-150 | 13-150 |

| BW | 11 | 40-300 | 25-150 | 13-150 |

| D1 | 12a | 75-800 | 8-35 | 13-400 |

| D3 | 12b | 225-450 | 18-29 | 40-127 |

Comparison Chart for Hardness Grade

| China GB2484-2495-84 | Russia | America Norton | Universal Co. | Japan |

| D,E,F | BM1,BM2 | A B C D E F G H | E F G H | E F G H I J K |

| G | M1 | |||

| H | M2 | |||

| J | M3 | |||

| K | CM1 | I J K L | ||

| L | CM2 | |||

| M | C1 | I J K L M N O P | M N O P | L M N O |

| N | C2 | |||

| P | CT1 | Q R S T U V W X Y Z | Q R S | P Q R S |

| Q | CT2 | |||

| R | CT3 | |||

| S | T1 | |||

| T | T2 | |||

| Y | BT1 | T U V W X Y Z | T U V W X Y Z | |

| BT2 |

China Hardness Grade

| Hard grade | Very soft | Soft | Medium soft | Medium | Medium hard | Hard | Very hard | |||||||

| Very soft | 1 | 2 | 3 | 1 | 2 | 1 | 2 | MH1 | MH2 | MH3 | Hard1 | Hard2 | Very hard | |

| Code | ABCDEF | G | H | J | K | L | M | N | P | Q | R | S | T | Y |

Suggested Applications According to Grain Size Differences

| Grit Number | Suggested Applications |

| F4,F5,F6,F7,F8,F10,F12,F14,F16,F20,F22,F24,F30 | Initial finishing and cutting |

| F36,F40,F46,F54 | Normal purpose semi-final finishing |

| F60,F70,F80,F90,F100 | Normal purpose final finishing |

| F120,F150,F180,F220,F230,F240,F280,F320,F360,F400 | Precision Grind, honing and tread Grinding |

| F500,F600,F800,F1000,F1200 | Mirror finish grinding, precision grinding |

Related Names

Abrasive Tool | Bonded Abrasive | Vitrified Bonded Grinding Wheels

Related Products

Scan QR to Read

Links:https://www.globefindpro.com/products/72826.html

Links:https://www.globefindpro.com/products/72826.html

Recommended Products