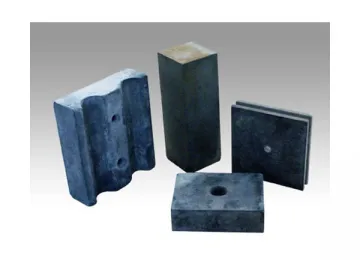

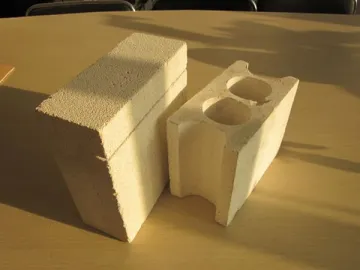

Mullite Brick

The mullite brick is a kind of light-weight mullite product made of top-quality high purity refractory powders and proportional organic composite padding by means of vacuum extrusion and high temperature sintering.

Features of Mullite Brick

1.Low thermal conductivity and low hot melting

2.High purity and low impurity content

3. High-temperature resistant, allowing for direct touch with fire

4.Very low weight and satisfactory thermal shock resistance

5.Precision dimension, allowing for arbitrary cutting

Applications of Mullite Brick

The high-temperature mullite brick is well applicable for hot surface lining and back lining of various industrial furnaces (like cracking furnace, heating furnace, resistance furnace, roller furnace, thermal treatment furnace, etc.) in the metallurgical industry, petrochemical industry, building materials industry, ceramic industry, machinery industry, etc.

Technical Indicators of Mullite Brick

| Type | Mullite Brick | Corundum- mullitebrick | Corundum- mullitekiln furniture | Mullite- cordierite kiln furniture | |

| Properties | SAS-70 | FAS-70 | |||

| Al2O3(%) ≥ | 70 | 70 | 85 | 85 | 45 |

| SiO 2 (%) ≤ | 24 | 25 | 12.5 | 40-45 | |

| Fe2O3 ( % ) ≤ | 1 | 0.5 | 0.5 | 1 | 1.4 |

| R2O (%) ≤ | 1.5 | 0.5 | |||

| Bulk density (g/cm 3 ) ≥ | 2.55 | 2.58 | 2.85 | 1.8-2.2 | |

| Apparent porosity (%) ≤ | 17 | 16 | 15 | 30 | |

| Cold crushing strength (Mpa) ≥ | 45 | 80 | 85 | 110 | 40 |

| Refractoriness under load 0.2Mpa (℃ ) ≥ | 1650 | 1700 | 1700 | 1700 | 1380 |

| Reheating linearchange (%) | ±0.1(1600℃*2h) | ±0.1(1650℃*2h) | ±0.2(1650℃*2h) | ||

| Cold Fracture resistance (Mpa) ≥ | 15 | 20 | 15 | 8 | |

| Fracture resistance at high temperature (Mpa)≥ | 8 | 12 | 11 | 12 | 8 |

| Thermal shock resistance (times) (1100 ℃ -water cooling) | 25 | 30 | 40 | 25 | 40 |

| Thermal expansion coefficient (1000ºC) | 3.3 | ||||

Related Names

High-Alumina Refractory Material | Sintered Product | High-Purity Firebrick

Related Products

Links:https://www.globefindpro.com/products/72834.html