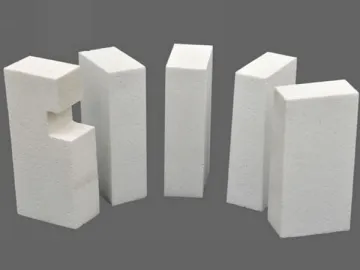

Insulation Brick

Being a leading refractories supplier in China, CHUO CHENG is able to provide several top-level insulation bricks, including light-weight clay insulation brick, light-weight high-alumina insulation brick, light-weight mullite insulation brick and alumina hollow sphere insulation brick.

These delicately made insulation bricks can be used as hot surface refractory lining or thermal-protective coating for back lining of other refractories. They are well applicable for smelting furnace, calcining kiln, flue, refining unit, heating unit, regenerating unit, gas producer and pipeline, soaking pit, annealing furnace, reaction chamber and other industrial thermal equipment.

Technical Indicators of Insulation Brick

| Indicators | Al2O3 (%)≥ | Fe2O3 (%)≤ | Bulk density (g/cm3) ≥ | Cold crushing strength (Mpa) ≥ | Refractoriness(℃) ≥ | Thermal shock resistance (times) (1100 ℃ -water cooling) | Thermal conductivity (W/M.K) (350℃±25℃) ≤ |

| Type | |||||||

| Light-weight clay insulation brick | |||||||

| NGQ/1.0 | 1 | 2.9 | 1350 | 0.5 | |||

| NGQ/0.9 | 0.9 | 2.5 | 1300 | 0.4 | |||

| NGQ/0.8 | 0.8 | 2.5 | 1250 | 0.35 | |||

| NGQ/0.7 | 0.7 | 1.9 | 1250 | 0.35 | |||

| NGQ/0.6 | 0.6 | 1.5 | 1200 | 0.25 | |||

| Light-weight high-alumina insulation brick | |||||||

| LGQ/-0.1 | 48 | 1 | 3.92 | 1400 | 0.5 | ||

| LGQ/0.9 | 48 | 0.9 | 3.43 | 1400 | 0.45 | ||

| LGQ/0.8 | 48 | 0.8 | 2.94 | 1400 | 0.35 | ||

| LGQ/0.7 | 48 | 0.7 | 2.45 | 1350 | 0.35 | ||

| LGQ/0.6 | 48 | 0.6 | 1.96 | 1350 | 0.3 | ||

| Light-weight mullite insulation brick | |||||||

| ASQ/0.8 | 65 | 0.8 | 0.8 | 5 | 1450 | 15 | 0.3 |

| ASQ/0.9 | 65 | 0.8 | 0.9 | 6 | 1450 | 15 | 0.35 |

| ASQ/0.10 | 65 | 0.8 | 1 | 7 | 1450 | 15 | 0.4 |

| Alumina hollow sphere insulation brick (Refractoriness ≥1850℃) | |||||||

| BAQ | ≥98.5 | 0.1 | 1.2-1.4 | 8 | Linear expansion rate( %) 1300℃ | 1700 | |

| 0.7-0.8 | |||||||

Related Names

Heat Insulation Product | Thermal Insulation Engineering | Industrial Insulation Brick

Related Products

Links:https://www.globefindpro.com/products/72856.html