Ceramic Fiber Blanket

Product Number: SC-CFB

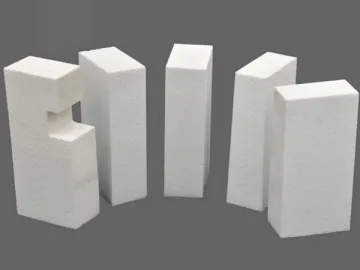

The ceramic fiber blanket is made of special aluminum silicate ceramic long filament fiber using special double-sided needling technology. The double-sided needling technology significantly improves fiber interlacing degree, split resistance, tensile strength and surface flatness.

The ceramic fiber blanket contains zero organic bonding agent, ensuring excellent plasticity and stability in high-temperature and low-temperature operating conditions. Besides, it is spotlessly white in color and uniform in size, integrating fire resistance, thermal insulation and heat preservation. The insulation material can also remain satisfactory tensile strength, toughness and fiber structure when used in neutral gas and oxidizing gas for a long time.

Features

1. High tensile strength and low shrinkage

2. Great resiliency with low heat storage

3. Low thermal conductivity

4. Good sound absorption

Applications

The ceramic fiber blanket has an up to 950-1400 ℃ refractoriness, well applicable for high-temperature insulation and heat preservation in aerospace industry, steel industry and petrochemical industry, fire resistance and thermal insulation of military equipment and electric component, thermal insulation and heat preservation of wall lining and back lining of industrial kiln and heating equipment, high-temperature equipment, high-temperature pipeline. Besides, the ceramic fiber blanket can be used as the raw material of high-temperature spacer, module, collapse block, etc.

Technical Indicators of Ceramic Fiber Blanket

| Common | Standard | Pure | High aluminum | Zirconium | ||

| Classification temperature(℃) | 1100 | 1260 | 1260 | 1360 | 1430 | |

| Operating temperature(℃) | <1000 | 1050 | 1100 | 1200 | 1350 | |

| Color | White | White | Pure white | Pure white | Pure white | |

| Bulk density (kg/m3) | 96 128 | 96 128 | 96 128 | 128 160 | 128 160 | |

| Permanent linear shrinkage(%) (after 24hours,density 128 kg/m3) | -4 (1000) | -3 (10 5 0) | -3 (1100) | -3 (1250) | -3 (1350) | |

| Thermal conductivity (w/m.k, density 128 kg/m3) | 0.09(400) 0.176(800) | 0.0 8 (400) 0.1 8 (800) | 0.09(400) 0.176(800) 0.22(1000) | 0.132(600) 0.22(1000) | 0.76(600) 0.22(1000) | |

| Tensile strength (Mpa, density128 kg/m3) | 0. 04 | 0. 04 | 0. 04 | 0. 04 | 0. 04 | |

| Chemicalcomposition(%) | AL2O3 | 44 | 46 | 47--49 | 52-55 | 39-40 |

| AL203 SIO2 | 96 | 97 | 99 | 99 | - | |

| AL2O3 SIO2 Zro2 | - | - | - | - | 99 | |

| Zro2 | - | - | - | - | 15-17 | |

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

| Dimensions(mm) | Common 7200*610*10-50, others up to clients | |||||

Related Names

Aluminum Silicate Fiber Blanket | Ceramic Fiber Blowing Blanket | Spun Ceramic Fiber Blanket

Related Products

Links:https://www.globefindpro.com/products/72859.html