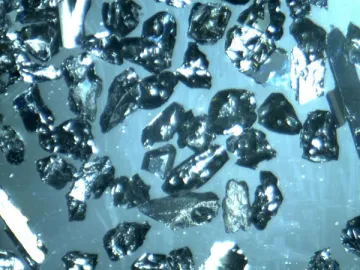

Green Silicon Carbide Abrasive

Product Number: SC-GC

Taking petroleum coke and quality silica as its main raw materials and halite as additive, the green silicon carbide abrasive is processed via high-temperature smelting in resistance furnace.

The green silicon carbide abrasive features crisp and sharp characteristics, good hardness (between corundum and diamond), higher mechanical strength than corundum, well suitable for various multi-purpose abrasive tools and cutting abrasives like grinding wheel, abrasive paper, abrasive belt, etc.

Technical Indicators of Green Silicon Carbide Abrasive

| Grit | SiC | F.C. | Fe2O3 |

| F12-F90 | 99.50%min | 0.20%max | 0.20%max |

| F100-F150 | 98.50%min | 0.25%max | 0.50%max |

| F180-F220 | 97.50%min | 0.25%max | 0.70%max |

| F230-F400 | 97.00%min | 0.30%max | 0.70%max |

| F500-F800 | 95.50%min | 0.40%max | 0.70%max |

| F1000-F1200 | 94.00%min | 0.50%max | 0.80%max |

| P12-P90 | 98.50%min | 0.25%max | 0.25%max |

| P100-P150 | 98.0%min | 0.30%max | 0.55%max |

| P180-P220 | 97.00%min | 0.30%max | 0.80%max |

| P240-P1000 | 96.50%min | 0.40%max | 0.80%max |

| P1200-P2500 | 94.50%min | 0.45%max | 0.90%max |

Bulk Density Index (g/ cm3)

| Grit No. | F12 | F16 | F20 | F24 | F30 | F36 | F46 |

| B.D. | 1.45-1.59 | 1.44-1.58 | 1.44-1.58 | 1.43-1.57 | 1.43-1.57 | 1.41-1.55 | 1.39-1.53 |

| Grit No. | F60 | F80 | F100 | F120 | F150 | F180 | F220 |

| B.D. | 1.37-1.51 | 1.36-1.50 | 1.35-1.49 | 1.33-1.47 | 1.31-1.45 | 1.30-1.44 | 1.30-1.44 |

Related Names

Synthetic Abrasive | Artificial Abrasive

Related Products

Scan QR to Read

Links:https://www.globefindpro.com/products/72870.html

Links:https://www.globefindpro.com/products/72870.html

Recommended Products

-

Fused Zirconia Mullite

Fused Zirconia Mullite

-

Gantry Crane(for Shipbuilding, Double Girder)

Gantry Crane(for Shipbuilding, Double Girder)

-

Gantry Crane(for Subway Construction, Double Girder)

Gantry Crane(for Subway Construction, Double Girder)

-

Electric Gantry Crane (Single Girder)

Electric Gantry Crane (Single Girder)

-

Cordierite Powder

Cordierite Powder

-

Semi Gantry Crane

Semi Gantry Crane

-

Brown Fused Alumina

Brown Fused Alumina

-

Sub-White Fused Alumina

Sub-White Fused Alumina

-

White Fused Alumina

White Fused Alumina

-

Bridge Crane(Double Girder with Electric Hoist)

Bridge Crane(Double Girder with Electric Hoist)

-

Gantry Crane(with Grab Bucket)

Gantry Crane(with Grab Bucket)

-

Calcium Aluminate Cement

Calcium Aluminate Cement

Hot Products