Corundum Brick

Product Number SC-GYZ

The corundum brick with more than 90% alumina is a refractory material taking corundum as its main crystal phase. The corundum brick features excellent chemical stability, satisfactory resistance to acid or alkali slag, metal and vitreous humor, mainly suitable for iron making blast furnace and blast-furnace hot blast stove, steel-making secondary refining furnace, glass melting furnace, petrochemical furnace, etc.

Technical Indicators of Corundum Brick

| Product number | WA99 | WA98 | WA97 | WA95 | WA93 | WA90 |

| Properties | ||||||

| Refractoriness (℃) | 1850 | 1850 | 1800 | 1750 | 1700 | 1650 |

| Al2O3 (% )≥ | 99 | 98 | 97 | 95 | 93 | 90 |

| Fe2O3 (% ) ≤ | 0.15 | 0.2 | 0.3 | 0.4 | 0.5 | 0.8 |

| Bulk density (g/cm3) | 3.15 | 3.15 | 3.1 | 3 | 2.95 | 2.9 |

| Apparentporosity (%) ≤ | 20 | 20 | 20 | 20 | 20 | 20 |

| Cold crushing strength (Mpa) ≥ | 90 | 90 | 80 | 80 | 80 | 80 |

| Refractoriness under load 0.2 Mpa (℃ ) ≥ | 1800 | 1800 | 1750 | 1700 | 1700 | 1600 |

| Reheating linear change (%) | ±0.1 (1700℃*2h) | ±0.15 (1700℃*2h) | ±0.2 (1700℃*2h) | ±0.2 (1650℃*2h) | ±0.3 (1650℃*2h) | ±0.3 (1600℃*2h) |

Related Names

Refractory Product | Refractory Brick | High-Temperature Material

Related Products

Scan QR to Read

Links:https://www.globefindpro.com/products/72882.html

Links:https://www.globefindpro.com/products/72882.html

Recommended Products

-

Gantry Crane(Single Girder with L-Shaped Leg)

Gantry Crane(Single Girder with L-Shaped Leg)

-

Explosion Proof Overhead Crane

Explosion Proof Overhead Crane

-

Overhead Crane(with Rotary Spreader Beam)

Overhead Crane(with Rotary Spreader Beam)

-

Insulating Overhead Crane

Insulating Overhead Crane

-

Gantry Crane(Double Girder)

Gantry Crane(Double Girder)

-

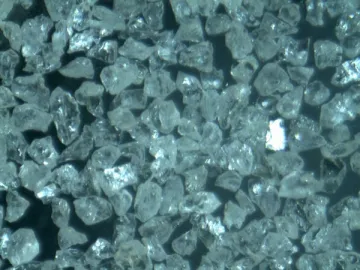

White Fused Alumina Abrasive

White Fused Alumina Abrasive

-

Tabular Alumina

Tabular Alumina

-

Manual Bridge Crane (Single Girder)

Manual Bridge Crane (Single Girder)

-

Magnesium Aluminate Spinel

Magnesium Aluminate Spinel

-

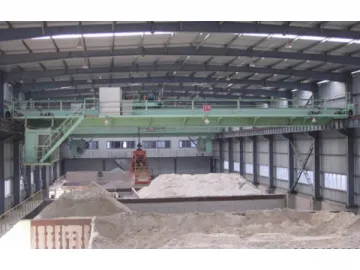

Bridge Crane (with Grab Bucket)

Bridge Crane (with Grab Bucket)

-

Bridge Crane(with Magnet Lifter)

Bridge Crane(with Magnet Lifter)

-

Semi Gantry Crane

Semi Gantry Crane