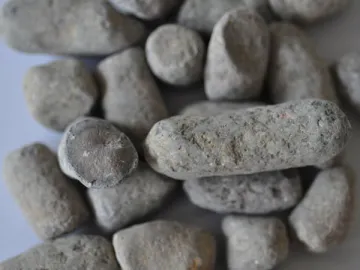

Mullite

The mullite is a top-quality refractory material, featuring homogeneous expansion, great thermal shock resistance, high load softening point, small high-temperature dislocation creep, excellent corrosion resistance, etc. The artificial refractory material is applicable for inner liners of various kilns and electric furnaces.

The two major methods to make mullite are electric smelting (high-temperature electric smelting in electric arc furnace) and sintering (high-temperature sintering in tunnel kiln).

Note: sintered mulltie is classified into bauxite-based sintered mulltie and alumina-based high-purity sintered mulltie.

Technical Indicators of Electric Smelting Mullite

| Product number | SC-FM70 | SC-FM75 | |

| Chemical composition % | Al2O3 | 70-74 | 74-77 |

| SiO2 | 25-28 | 22-25 | |

| Fe2O3 | 0.1max | 0.1max | |

| K2O Na2O | 0.5max | 0.5max | |

| CaO | 0.3max | 0.3max | |

| Mullite phrase content (%) | 95min | ||

| Glass phrase content (%) | 5max | ||

| Linear expansion coefficient(1/ºC ) | -6.0*10 -6 | ||

| True specific gravity | 3.2min | ||

| Refractoriness (ºC) | 1840min | ||

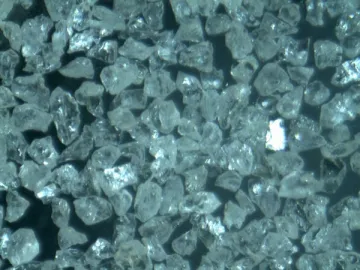

| Grain size of section sand(mm) | 0-1/1-3/3-5... | ||

| Powder(mesh) | -200 -325... | ||

Technical Indicators of Bauxite-Based Sintered Mullite

| Product number | Chemical composition (%) | Water absorbing capacity (%) | Bulk density (g/cm3) | |||

| Al2O3 | SiO2 | Fe2O3 | R2O | |||

| MS70 | 68-73 | 22-28 | ≤1.2 | ≤0.3 | ≤3.0 | ≥2.8 |

| MS60 | 58-62 | 28-33 | ≤1.1 | ≤0.3 | ≤3.0 | ≥2.6 |

| MS45 | 42-45 | 53-55 | ≤0.4 | ≤1.6 | ≤3.0 | ≥2.5 |

Technical Indicators of Alumina-Based High-Purity Sintered Mullite

| Product number | Chemical composition (%) | Apparent porosity (%) | Bulk density (g/cm3) | |||

| Al2O3 | SiO2 | Fe2O3 | R2O | |||

| XMS75 | ≥75 | 21-24 | ≤0.5 | ≤0.3 | ≤3.0 | ≥2.85 |

| XMS70 | 70-73 | 26-29 | ≤0.5 | ≤0.3 | ≤3.0 | ≥2.80 |

| XMS60 | 58-61 | 38-41 | ≤0.5 | ≤0.3 | ≤4.0 | ≥2.70 |

Related Names

Fused Mullite | Refractory Material

Related Products

Links:https://www.globefindpro.com/products/72891.html

-

Bridge Crane (with Hook and Grab Bucket)

Bridge Crane (with Hook and Grab Bucket)

-

Ladle Crane (Four-Girder)

Ladle Crane (Four-Girder)

-

Suspension Crane (with Magnetic Lifter)

Suspension Crane (with Magnetic Lifter)

-

Ladle Crane(Double Girder, 75/20-125/32 Ton)

Ladle Crane(Double Girder, 75/20-125/32 Ton)

-

Bridge Crane(Double Girder, Heavy Duty)

Bridge Crane(Double Girder, Heavy Duty)

-

Hydraulic Aerial Work Platform(with Aluminum Alloy Mast)

Hydraulic Aerial Work Platform(with Aluminum Alloy Mast)

-

Ladle Crane(Double Girder, 5-74Ton)

Ladle Crane(Double Girder, 5-74Ton)

-

Bridge Crane(Double Girder, European Standard)

Bridge Crane(Double Girder, European Standard)

-

White Fused Alumina Abrasive

White Fused Alumina Abrasive

-

Gantry Crane(Double Girder)

Gantry Crane(Double Girder)

-

Insulating Overhead Crane

Insulating Overhead Crane

-

Overhead Crane(with Rotary Spreader Beam)

Overhead Crane(with Rotary Spreader Beam)