Grab Bucket

| Name | Grab |

| Model | ZD |

| Volume | 0.25~55m3 |

| Working class | Light, mid, heavy, super heavy |

Brief Description

The grab bucket is a lifting tool usually situated on a crane to grab silt and all kinds of bulk cargos. This lifting grab is mainly divided into two equal halves or several crescent-shaped jaws which can be opened and closed for grabbing and unloading bulk materials. As a specialist grab crane supplier, YUNTIAN provides a complete line of grab buckets. See their detailed classifications below.

Classifications of Grab Bucket

1. According to shapes, our grab bucket can be classified into clamshell grab and orange peel bucket. The former is composed of two clamshells while the later is made up of three or more crescent-shaped jaws resembling segments of orange peel hinged to a single support at the top.

2. According to drive modes, it can be classified into hydraulic grab and mechanical grab bucket. To be specific, the hydraulic grab bucket employs hydraulic source to offer power to the hydraulic cylinder, then driving the movement of clamshells or jaws. This grab itself is fitted with hydraulic system.

The mechanical grab bucket itself has no opening and closing mechanism. It is mainly opened and closed, with the aid of rope or external force. Depending on operational characteristics, the mechanical type grab can be divided into single rope grab, double rope grab, four rope grab. Among which, the most commonly used one is the four rope grab.

Applications of Grab Bucket

1. Clamshell Grab

The clamshell grab is mainly used in ports, docks, railway station goods yard, mine fields, etc. for handling all kinds of bulk materials, minerals, coal, sand, stone and so on. It is also ideal for rock excavation, foundation trench excavation, highway construction, track laying engineering and other projects.

2. Orange Peel Bucket

The orange peel bucket is a popular grab bucket used in various harsh environments for loading and unloading large block materials and rubbish. For instance, it has been widely used in ports as well as railway, metallurgical, mining and building industries. It is available in four types including single rope, double rope, four rope and electric type.

According to materials size, the orange peel jaws can be independently closed. The number of jaws depends on the materials to be grabbed or user’s demand.

3. Mechanical Grab

Single rope grab is suitable for all kinds of cranes which have only one hoisting drum. Advanced opening and closing mechanism allows unrestricted open and close during handling materials as well as convenient hanging. This type of grab bucket is suitable both sea and land operation.

Double rope grab is ideal for the cranes with double hoisting mechanisms. It features excellent reliability, great convenience, high efficiency and wide purposes. Typically, it is mainly used in ports and docks as well as road and bridge constructions for grabbing bulk materials.

The mechanical grab bucket will turn into four rope grab with two sets of double rope. The working principle of four rope grab is same as that of double rope grab.

4. Hydraulic Grab

The hydraulic grab bucket is characterized by compact structure, striking appearance, energy conservation, easy operation, large grabbing capacity and high automation. It is ideal material handling equipment for grabbing large size mineral, cast iron, scrap steel, garbage, iron powder, straw, slag and other materials. Typical applications are in steel, mining and forestry industries as well as ports, garbage disposal station, biomass power station, etc.

5. Timber Grab

The timber grab bucket is mainly used for grabbing and handling logs, lumber, pipes, drums and objects with different specifications. It also includes clamshell grab and orange peel bucket, matched with tower crane and portal crane.

6. Straw Bundle Grab

The straw bundle grab is also a kind of grab bucket supplied by YUNTIAN. It serves as material handling equipment in power plant, and is mainly used to handle straw bales. Especially, this grab is ideally suitable for straw warehouse of power plant where working environment is damp and full of dust. However, our straw bundle grab can uninterruptedly work there.

Technical Parameters of Grab Bucket (Four Rope Grab)

| Volume (m3) | Working Class | Material density (t/m3) | Pulley multiply power | Wire rope diameter (mm) | Pulley diameter (mm) | Grab dead weight (kgs) | Crane capacity (t) | Head size: A×B×H (mm) | Max. opening D (mm) | Remarks |

| 1 | Heavy | >1.8-2.9 | 5 | Φ14 | Φ350 | 2.1 | 5 | 1850×1224×2635 | 2544 | |

| 1.5 | Mid | >1-1.8 | 5 | Φ14 | Φ350 | 2.25 | 5 | 2150×1324×2765 | 2798 | |

| 2.5 | Light | >0.5-1 | 3 | Φ14 | Φ350 | 2.38 | 5 | 2350×1570×2985 | 3227 | |

| 2 | Heavy | >1.8-2.9 | 5 | Φ18 | Φ500 | 3.94 | 10 | 2410×1612×3184 | 3070 | |

| 3 | Mid | >1.0-1.8 | 5 | Φ18 | Φ500 | 4.4 | 10 | 2650×1642×3301 | 3308 | |

| 5 | Light | >0.5-1 | 3 | Φ18 | Φ500 | 4.6 | 10 | 2950×1988×3549 | 3790 | |

| 3 | Heavy | >1.8-2.9 | 5 | Φ21.5 | Φ610 | 6.4 | 15 | 2616×1806×3856 | 3326 | |

| 4.5 | Mid | >1-1.8 | 5 | Φ21.5 | Φ610 | 6.98 | 15 | 2956×1906×4076 | 3756 | |

| 2.5 | Light | 0.86 | 4 | Φ18 | Φ500 | 2.83 | 5 | 2350×1560×3350 | 3150 | |

| 2 | Mid | >1-1.6 | 5 | Φ16 | Φ400 | 2.5 | 5 | 2200×1500×2926 | 3000 | |

| 5 | Heavy | 2 | 6 | Φ19.5 | Φ500 | 9.6 | 20 | 2950×1914×4820 | 5000 | Tooth |

| 1.8 | Heavy | 2-2.8 | 5 | Φ19.5 | Φ500 | 5.5 | 10 | 2150×1470×3340 | 3200 | |

| 9 | Light | 0.95 | 3 | Φ16 | Φ400 | 7.4 | 15 | 3385×2356×4695 | 4900 | |

| 0.5 | Heavy | >1.7-2.5 | 5 | Φ27 | Φ700 | 2 | 5 | 1600×950×2197 | 1800 |

Technical Parameters of Grab Bucket (Electric Grab)

| Volume (m3) | Working Class | Material density (t/m3) | Pulley multiply power | Wire rope diameter (mm) | Pulley diameter (mm) | Power (Kw) | Grab dead weight (kgs) | Crane capacity (t) | Head size: A×B×H (mm) | Max. opening D (mm) |

| 1 .5 | Heavy | ≤2 | 5 | Φ15 | Φ350 | 15 | 2. 9 | 5 | 1950×1450×3560 | 2800 |

| 2 | Heavy | ≤2 | 5 | Φ15 | Φ350 | 18.5 | 3.6 | 10 | 2300×1400×3870 | 3000 |

| 2.5 | Heavy | ≤2 | 5 | Φ16 | Φ400 | 22 | 4.4 | 10 | 2500×1650×4100 | 3100 |

| 3 | Mid | ≤1.2 | 5 | Φ16 | Φ400 | 22 | 4.68 | 10 | 2500×1896×4140 | 3200 |

| 6 | Light | ≤1 | 5 | Φ16 | Φ400 | 22 | 5.6 | 15 | 2800×2196×4540 | 3700 |

| 1 | Heavy | ≤2.5 | 4 | Φ15 | Φ350 | 11 | 2.8 | 5 | 2100×1100×3467 | 2600 |

| 5 | Light | ≤1 | 4 | Φ17.5 | Φ400 | 22 | 4.1 | 10 | 2800×2035×4440 | 3700 |

Technical Parameters of Grab Bucket (Hydraulic Grab)

| Volume (m3) | Grab dead weight (Kgs) | Crane capacity (t) | Power (Kw) | Working pressure Bar | Close time (s) | Appearance size: (mm) | |||

| H | H1 | A | B | ||||||

| 0.5 | 1.5 | 5 | 11 | 180 | 10 | 2180 | 1880 | 1570 | 2160 |

| 0.6 | 1.7 | 10 | 11 | 180 | 11 | 2190 | 1900 | 1600 | 2220 |

| 0.8 | 2.0 | 10 | 15 | 180 | 13 | 2380 | 1980 | 1700 | 2480 |

| 1.0 | 2.5 | 10 | 15 | 180 | 14 | 2410 | 2070 | 1800 | 2700 |

| 2 | 4.2 | 15 | 22 | 200 | 16 | 3330 | 2820 | 2220 | 3400 |

| 2.5 | 2.6 | 5 | 18.5 | 180 | 17 | 3214 | 2895 | 2247 | 3572 |

| 3 | 3.8 | 10 | 18.5 | 180 | 20 | 3214 | 2876 | 2500 | 3680 |

Optional Configurations of Grab Bucket

| Grab model | Hydraulic grab |

| Electrical parts | SCHNEIDER, SIEMENS, CHINT |

| VFD | SCHNEIDER, SIEMENS, CHINT , YASKAWA |

| Motor | XINDALI, JMU, ABM. ABB, WEG. SIEMENS or any special specified |

| Reducer | TAILONG, TAIXING, SEW or any special specified |

| Working duty | A6/A7/A8 |

| Overload limiter | YES/NO |

| Audible and visual alarm | YES/NO |

Show Details of Grab Bucket

Links:https://www.globefindpro.com/products/72909.html

-

Low Speed Electric Winch

Low Speed Electric Winch

-

Ship to Shore Container Crane

Ship to Shore Container Crane

-

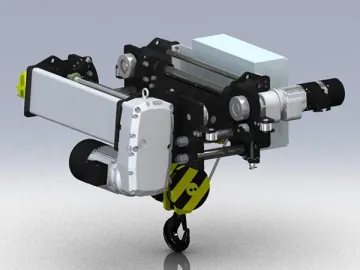

Electric Wire Rope Hoist (for Metallurgy)

Electric Wire Rope Hoist (for Metallurgy)

-

Wall Mounted Jib Crane

Wall Mounted Jib Crane

-

Continuous Sterilization Equipment( Vertical Retort for Sterilizing Metal Cans)

Continuous Sterilization Equipment( Vertical Retort for Sterilizing Metal Cans)

-

Level Luffing Crane

Level Luffing Crane

-

Rubber Tyred Gantry Crane (RTG)

Rubber Tyred Gantry Crane (RTG)

-

Self-Propelled Scissor Lift

Self-Propelled Scissor Lift

-

High Speed Electric Winch

High Speed Electric Winch

-

Electric Wire Rope Hoist (with Variable Frequency Drive)

Electric Wire Rope Hoist (with Variable Frequency Drive)

-

Electric Wire Rope Hoist (Explosion Proof)

Electric Wire Rope Hoist (Explosion Proof)

-

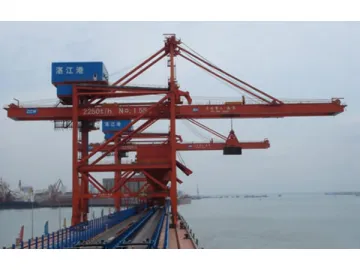

Port Crane (Grab Type Ship Unloader)

Port Crane (Grab Type Ship Unloader)