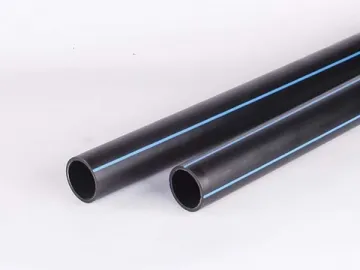

PE Pipe

Application

Our PE pipe is suitable for delivering water, natural gas, coal oven gas, ore sand and mud slurry in cities, food and chemical industry. It can also serve as replacement for cement pipe, cast iron pipe, steel pipe and landscape water supply pipe.

Features

1. The PE pipe we produce has excellent erosion resistance and will work well even when the temperature falls sharply.

2. With high strength and flexibility, our polyethylene pipe is of high adaptive capacity to uneven foundations and is resistant to earthquake and typhoon.

3. Our product features good weather fastness (anti-UV) and long-term thermal stability.

4. You do not need to take special consideration about the surroundings, water quality or soil quality when you lay the pipelines since our PE pipes are highly resistant to inorganic salt, inorganic acid, alkali metal, organic matter and other corrosive chemical substances.

5. Thanks to smooth inner wall, our PE water pipe has low flow resistance and high flow capacity, thereby helping reduce construction cost.

6. Our PE pipe is applicable for both traditional excavation construction mode and new trenchless construction mode such as pipe-jacking, directional drilling, pipe lining, pipe cracking and water sinking.

7. The PE material we use only contains the carbon and hydrogen elements. Hence, our PE gas pipe is environmentally friendly and non-toxic. It is completely in conformity with the national standard.

8. As a trustworthy pipe system suppler, we can offer you polyethylene pipes which are durable and have long lifespan.

Parameters of PE Pipe

| SDR21/0.8Mpa | |

| Specification (mm) | Wall Thickness (mm) |

| 90 | 4.3 |

| 110 | 5.3 |

| 125 | 6.0 |

| 140 | 6.7 |

| 160 | 7.7 |

| 180 | 8.6 |

| 200 | 9.6 |

| 225 | 10.8 |

| 250 | 11.9 |

| 280 | 13.4 |

| 315 | 15.0 |

| 355 | 16.9 |

| 400 | 19.1 |

| 450 | 21.5 |

| 500 | 23.9 |

| 560 | 26.7 |

| 630 | 30.0 |

| SDR13.6/1.25Mpa | |

| Specification (mm) | Wall Thickness (mm) |

| 63 | 4.7 |

| 75 | 5.6 |

| 90 | 6.7 |

| 110 | 8.1 |

| 125 | 9.2 |

| 140 | 10.3 |

| 160 | 11.8 |

| 180 | 13.3 |

| 200 | 14.7 |

| 225 | 16.6 |

| 250 | 18.4 |

| 280 | 20.6 |

| 315 | 23.2 |

| 355 | 26.1 |

| 400 | 29.4 |

| 450 | 33.1 |

| 500 | 36.8 |

| 560 | 41.2 |

| 630 | 46.3 |

| SDR11/1.6Mpa | |

| Specification (mm) | Wall Thickness (mm) |

| 20 | 2.0 |

| 25 | 2.3 |

| 32 | 3.0 |

| 40 | 3.7 |

| 50 | 4.6 |

| 63 | 5.8 |

| 75 | 6.8 |

| 90 | 8.2 |

| 110 | 10.0 |

| 125 | 11.4 |

| 140 | 12.7 |

| 160 | 14.6 |

| 180 | 16.4 |

| 200 | 18.2 |

| 225 | 20.5 |

| 250 | 22.7 |

| 280 | 25.4 |

| 315 | 28.6 |

| 355 | 32.2 |

| 400 | 36.3 |

| 450 | 40.9 |

| 500 | 45.4 |

| 560 | 50.8 |

| 630 | 57.2 |

Physical Properties of PE pipe

The physical properties of PE water supply pipe should be up to the requirement in this chart. When adding reused materials to the mixed raw materials for pipe extrusion, the difference between the melt mess-flow rate (5kg, 190℃) of the pipe and the MFR of the mixed materials should not exceed 20%.

| No. | Item | Requirement | Testing Methods | |

| 1 | Elongation at break (%) | ≥350 | GB/T8804.2 | |

| 2 | Longitudinal shrinkage rate (%) | ≤3 | GB/T6671.2 | |

| 3 | Oxidative induction time (min) | ≥20 | GB/T17391 | |

| 4 | Weather fastness (The pipes receive≥3.5GJ/m² aging energy totally) | 80℃ hydrostatic strength (165h) | No burst, no leakage | GB/T13663-2000, Article 7.11 |

| Elongation at break % | ≥350 | GB/T8804.2 | ||

| Oxidative induction time (200℃) min | ≥10 | GB/T17391 | ||

| Note: Applies only to blue pipes. | ||||

| Hydrostatic Strength | |||||

| Hydrostatic strength of our PE pipes should conform to the following requirements (GB/T6111) | |||||

| No. | Item | Hoop Stress (MPa) | Requirement | ||

| PE63 | PE80 | PE100 | |||

| 1 | 20℃ hydrostatic strength (100h) | 8.0 | 9.0 | 12.4 | No burst, no leakage |

| 2 | 80℃ hydrostatic strength (165h) | 3.5 | 4.6 | 5.5 | No burst, no leakage |

| 3 | 80℃ hydrostatic strength (1000h) | 3.2 | 4.0 | 5.0 | No burst, no leakage |

Links:https://www.globefindpro.com/products/72972.html

-

PVC-U Pipe (Plastic Electrical Conduit)

PVC-U Pipe (Plastic Electrical Conduit)

-

Oil Free Slide Plate

Oil Free Slide Plate

-

PVC-U Pipe (Plastic Drainage Pipe)

PVC-U Pipe (Plastic Drainage Pipe)

-

PPR Pipe (Multilayer Composite Pipe)

PPR Pipe (Multilayer Composite Pipe)

-

Guide Post Set

Guide Post Set

-

PE-RT Pipe (Underfloor Heating Pipe)

PE-RT Pipe (Underfloor Heating Pipe)

-

Guide Post

Guide Post

-

Oil Free Bushing

Oil Free Bushing

-

Brass Plumbing Fittings (PE-RT Pipe Fittings)

Brass Plumbing Fittings (PE-RT Pipe Fittings)

-

Mold Date Insert

Mold Date Insert

-

Guide Bushing

Guide Bushing

-

PPR Pipe Fittings

PPR Pipe Fittings