Flexible Metal Conduit

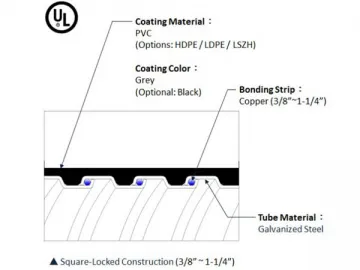

The square locked flexible metal conduit has a flat surface and features excellent flexibility and ductility. It can be directly installed for any use. This construction material's properties can be adjusted according to different use requirement and can be covered in a layer of woven mesh or coated in a special material that is oil, wear, cold and flame resistant.

Specifications

Materials: Stainless steel/Galvanized steel

Coating materials: PVC/HDPE/LDPE/LSZH

Coating colors: Black/grey

Working temperature range: -25℃~105℃

Waterproof grade: IP67

Certifications: EN (CE) / CCS

Technical Parameters of Flexible Metal Conduit (Square Locked)

| No. | I.D.(mm) | O.D.(mm) | O.D. after coated (mm) | Min. Bending Radius (mm) | Package length (m) | Materials |

| 1 | 6.8 | 9.0 | 10.0 | 40 | 50 | Stainless steel/ Galvanized steel |

| 2 | 10.3 | 13.0 | 14.0 | 40 | 50 | Stainless steel/ Galvanized steel |

| 3 | 13.0 | 16.0 | 17.0 | 50 | 50 | Stainless steel/ Galvanized steel |

| 4 | 16.9 | 20.5 | 21.5 | 60 | 50 | Stainless steel/ Galvanized steel |

| 5 | 21.4 | 25.0 | 26.0 | 80 | 50 | Stainless steel/ Galvanized steel |

| 6 | 28.1 | 32.0 | 34.0 | 100 | 25 | Stainless steel/ Galvanized steel |

| 7 | 37.7 | 42.5 | 44.5 | 110 | 25 | Stainless steel/ Galvanized steel |

| 8 | 48.4 | 53.0 | 55.0 | 130 | 25 | Stainless steel/ Galvanized steel |

| 9 | 57.5 | 62.5 | 64.5 | 150 | 10 | Stainless steel/ Galvanized steel |

| 10 | 63.3 | 67.5 | 72.6 | 150 | 10 | Stainless steel/ Galvanized steel |

| 11 | 78.4 | 84.2 | 88.4 | 180 | 5 | Stainless steel/ Galvanized steel |

| 12 | 102.1 | 108.0 | 113.8 | 240 | 5 | Stainless steel/ Galvanized steel |

Applications of the Flexible Metal Conduit (square locked)

1. It can be used for electronic wire protection in sensors, medical equipment, fire alarm systems, security protection equipment and more.

2. It is used in the protection of fiber optic cables, optical fiber sensors, and optical fiber communication systems.

3. This conduit has also been used for electrical cable protection in buildings where there is low risk of fire, elevators, computer facilities, solar equipment, cars, planes, and ships.

The interlocked flexible metal conduit comes with an outstanding flexibility, ductility and tensile strength and can be directly installed for use. Similar to the square locked conduit, this flexible conduit can also be adjusted to meet different use requirements. It can also be covered with a woven mesh or coated with special materials for a better performance.

The coating materials available have excellent resistance to oil, abrasions, cold and flame. In addition, the interlocked flexible metal conduit features a higher tensile strength as compared to that of the square locked conduit.

Specifications

Materials: stainless steel/galvanized steel

Coating materials: PVC/HDPE/LDPE/LSZH

Coating colors: black/grey

Working temperature range: -25℃ to 105℃

Waterproof grade: IP67

Certifications: EN (CE)/ ATEX (for TIL-001 to TIL-009)

Technical Parameters of Flexible Metal Conduit (Interlocked)

| No. | I.D.(mm) | O.D.(mm) | O.D. after coated (mm) | Min. Bending Radius (mm) | Package length (m) | Materials |

| 1 | 6.8 | 9.0 | 10.0 | 45 | 50 | Stainless steel/ Galvanized steel |

| 2 | 10.3 | 13.0 | 14.0 | 45 | 50 | Stainless steel/ Galvanized steel |

| 3 | 13.0 | 16.0 | 17.0 | 55 | 50 | Stainless steel/ Galvanized steel |

| 4 | 16.9 | 20.5 | 21.5 | 70 | 50 | Stainless steel/ Galvanized steel |

| 5 | 21.4 | 25.0 | 26.0 | 85 | 50 | Stainless steel/ Galvanized steel |

| 6 | 28.1 | 32.0 | 34.0 | 100 | 25 | Stainless steel/ Galvanized steel |

| 7 | 37.7 | 42.5 | 44.5 | 130 | 25 | Stainless steel/ Galvanized steel |

| 8 | 48.4 | 53.0 | 55.0 | 150 | 25 | Stainless steel/ Galvanized steel |

| 9 | 57.5 | 62.5 | 64.5 | 180 | 10 | Stainless steel/ Galvanized steel |

Applications of Flexible Metal Conduit (Interlocked)

1. This can be used in electronic wire protection in lighting equipment, communication equipment, sensors, medical equipment, fire alarm systems, and security equipment.

2. It can be used for power wire protection in buildings with a low risk of fire, machinery, elevators, computer facilities, car and plane industries, and other industries with harsh environments such as nuclear power, petrochemical industry, mining, and shipbuilding.

3. It can be used for kitchen and bathroom needs such as shower tubes, and kitchen counter wash pipes.

4. It can also be used in other applications such as gas pipes.

Links:https://www.globefindpro.com/products/72996.html

-

Plastic Snap-in Connector 180°

Plastic Snap-in Connector 180°

-

Liquid Tight Flexible Metal Conduit

Liquid Tight Flexible Metal Conduit

-

Copper Wire Braided Fiber Optic Cable

Copper Wire Braided Fiber Optic Cable

-

Quick Connector 180°

Quick Connector 180°

-

Multi-core Armored Cable

Multi-core Armored Cable

-

Waterproof Plastic Connector 90°

Waterproof Plastic Connector 90°

-

Waterproof Cable Connector 180°

Waterproof Cable Connector 180°

-

Armored Figure-8 Cable

Armored Figure-8 Cable

-

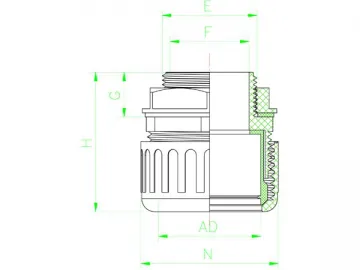

Electrical Conduit Fitting

Electrical Conduit Fitting

-

PEX Pipe (Anti-UV Plastic Tubing)

PEX Pipe (Anti-UV Plastic Tubing)

-

Punch Retainer

Punch Retainer

-

Guide Bush

Guide Bush