Armored Fiber Optic Cable for Mining

Our armored fiber optic cables for mining are commonly used as data transmission mediums and have obtained certificate number MA090054 for flame retardant performance. This mining cable not only has the complete advantages for armored fiber optic cables, but it also meets the specific requirements for the coal and mine industries, adding unique new performances.

This fiber optic cable, also known as a flame retardant cable is ideal for telecommunication applications in mining for coal, gold, iron and more. It is especially useful for communicating when accidents happen. As a professional telecommunication cable supplier, this fiber optic cable we supply for mining can meet your requirements.

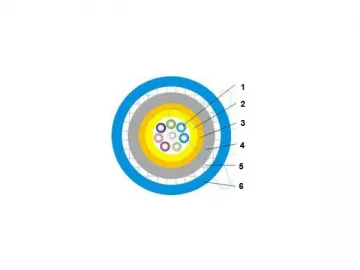

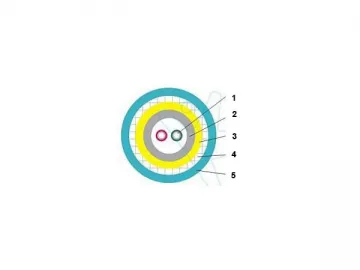

Product Structure

1. Tight buffer fiber

2. Aramid Yarn

3. PVC sheath

4. Stainless steel conduit

5. Stainless steel braiding

6. Flame retardant jacket

Geometrical Characteristics of Fiber Optic Cable for Mining

| Types | Φ6.0 | Φ6.9 | Φ8.0 | Φ8.5 | Φ9.0 |

| Dimensions (mm) | 6.0±0.1 | 6.9±0.1 | 8.0±0.1 | 8.5±0.1 | 9.0±0.1 |

| Number of fiber | 2/4/6 | 8/12 | 4/6 | 8 | 12 |

| Fiber diameter (μm) | 250 | 250 | 600 | 600 | 600 |

| Flame retardant performance | Meet the requirements of single cable vertical flame test and group burning test stipulated by MT-386-1995 | ||||

Mechanical Properties of Fiber Optic Cable for Mining

| Tensile strength(N) | Long Term | 600 |

| Short Term | 1000 | |

| Crush Resistance(N/100mm) | Long Term | 3000 |

| Short Term | 5000 | |

| Bending Radius(MM) | Dynamic | 20×D (D: Cable Diameter) |

| Static | 10×D (D: Cable Diameter) |

Fiber Characteristics of Fiber Optic Cable for Mining

| Single Mode | Multimode | ||

| 9/125 | 50/125 | 62.5/125 | |

| 1310/1550(nm) | 850/1300(nm) | 850/1300(nm) | |

| Max. peak attenuation (dB/km) | ≤0.10/1.2 | ≤3.5/1.5 | ≤3.5/1.5 |

| Min. bandwidth (MHZ-KM) | -- | ≥400/400 | ≥160/500 |

| Temperature range (℃) | -40 ℃ ~ 200 ℃ | ||

Links:https://www.globefindpro.com/products/73014.html

-

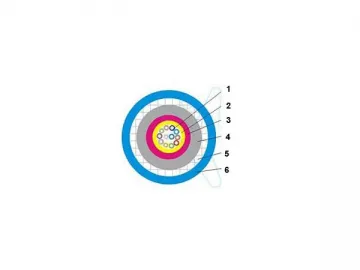

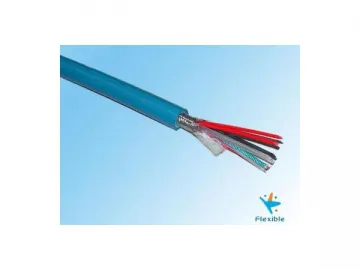

Bunched Cable (4-12 Cores)

Bunched Cable (4-12 Cores)

-

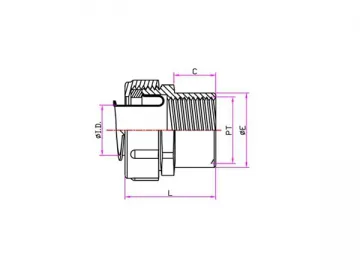

IMC Connector

IMC Connector

-

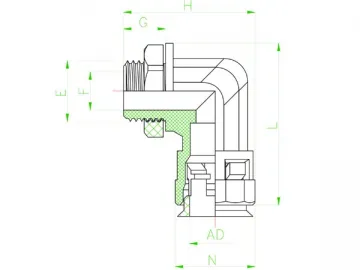

Quick Connector 90°

Quick Connector 90°

-

Armored Fiber Optic Cable for Temperature Sensing

Armored Fiber Optic Cable for Temperature Sensing

-

Dual-Core Armored Fiber Optic Patch Cable

Dual-Core Armored Fiber Optic Patch Cable

-

Silicone Sheathed Fiber Optic Sensing Cable

Silicone Sheathed Fiber Optic Sensing Cable

-

Waterproof Cable Connector 90°

Waterproof Cable Connector 90°

-

Armored Hybrid Fiber-Coaxial Cable

Armored Hybrid Fiber-Coaxial Cable

-

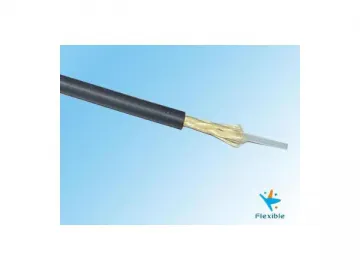

Single-Core Armored Cable

Single-Core Armored Cable

-

Seamless Tube Armored Fiber Optic Cable

Seamless Tube Armored Fiber Optic Cable

-

Liquid Tight Flexible Non-Metallic Conduit

Liquid Tight Flexible Non-Metallic Conduit

-

BX Connector

BX Connector