Digital SMD Soldering Desoldering Hot Air Preheat BGA Rework Station, Item WEP-853AAA

The 853AAA BGA rework station is an upgraded version of the 853AAA BGA rework station. The front interface features an aluminum panel designed with an elegant appearance. Built with a 3-segment parameter memory design, the machine can save function modes in different parameters for easier configuration when switching jobs and components. You can set the pre-heating time and air gun operation time to realize automatic de-soldering.

Technical Parameters

| Machine Parameters | |||

| Rated voltage | AC 220V±10% 50Hz | ||

| Power | ≤1270W | ||

| 300℃The thermostat power of (high-speed PID programmable energy saving) | 250W±10% | ||

| Working environment | 0~40℃ relative humidity<80% | ||

| Storage environment | -20~80℃ relative humidity<80% | ||

| Body size | L320xW220xH100mm±5mm | ||

| Weight | 6.5kg | ||

| Parts parameters | Hot air gun | Soldering iron |

| Work voltage | AC 220V±10% 50Hz | AC 26V±10% 50Hz |

| Output power | 650W | 75W |

| Temperature range | 100℃~480℃ | 200℃~480℃ |

| Airflow type | Brushless fan | --- |

| Air Flow | 120L/min | --- |

| Temperature Stability | ±1℃ (static) | ±1℃ (static) |

| Display Type | LED digital display | LED digital display |

| Temperature correction type | PID digital program | IPID digital program |

| PID Temperature correction cycle | Rapidly 20ms | High-speed 100ms |

| Heating elements | Ceramic skeleton heater | Imported heater |

| Tip ground impedance | --- | <2Ω |

| Tip of ground voltage | --- | <2mV |

| Pre-heater platform | |

| Work voltage | AC 220V±10% 50Hz |

| Output power | 600W |

| Temperature range | 50℃--400℃ |

| Temperature stability | ±2℃ (static) |

| Display type | LED digital display |

| Pre-heating platform area | 120X120mm |

| Pre-heating platform material | Ceramic heating material |

| Temperature sensor | Type K thermocouple |

| Temperature range | 50℃--400℃ |

Programmable hot air gun and pre-heating platform, the pre-heating platform allows for the setting of the operating time, working temperature, and airflow rate of the hot air gun to realize automatic de-soldering.

Temperature compensation function within ±80°C, automatically corrects the hot air gun and soldering iron temperature caused by environmental change or component maintenance and replacement.

The timing function allows operating time tracking from the beginning.

Air gun protection function will automatically power off the hot air gun if any malfunction occurs for safety assurance.

If you need quick after-sales support

Please don't hesitate to send an email to !

Scan QR to Read

Links:https://www.globefindpro.com/products/7315.html

Links:https://www.globefindpro.com/products/7315.html

Recommended Products

-

SMD Hot Tweezer Soldering Station, Item WEP-938D

SMD Hot Tweezer Soldering Station, Item WEP-938D

-

LCD Display Screen Separator Machine, Item WEP-946A-III

LCD Display Screen Separator Machine, Item WEP-946A-III

-

Sandblasting & Powder Coating Package System

Sandblasting & Powder Coating Package System

-

Vacuum Pick-Up Soldering Station Suitable for Small PCB Repair, Item WEP-850A(II)

Vacuum Pick-Up Soldering Station Suitable for Small PCB Repair, Item WEP-850A(II)

-

Multifunction Constant Temperature Digital Soldering Iron Station, Item WEP-926LED-II

Multifunction Constant Temperature Digital Soldering Iron Station, Item WEP-926LED-II

-

Cheap Electrostatic Powder Coating Machine COLO-500Star

Cheap Electrostatic Powder Coating Machine COLO-500Star

-

YIHUA 857D blower hot air rework station

YIHUA 857D blower hot air rework station

-

SMD Hot Tweezer Soldering Station, Item WEP-938D

SMD Hot Tweezer Soldering Station, Item WEP-938D

-

Digital SMD Soldering Desoldering Hot Air Preheat BGA Rework Station, Item WEP-853AAA

Digital SMD Soldering Desoldering Hot Air Preheat BGA Rework Station, Item WEP-853AAA

-

Pulse Powder Coating System Colo-610

Pulse Powder Coating System Colo-610

-

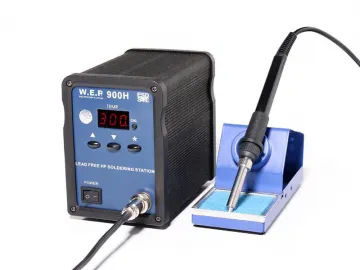

High Frequency Soldering Station, Item WEP-900H

High Frequency Soldering Station, Item WEP-900H

-

Vibration Powder Coating Unit, COLO-660-V

Vibration Powder Coating Unit, COLO-660-V

Hot Products