Process Piping

TIANBAO process piping has been widely applied to various industries. In food production industry, our tubing system is used to transport food materials to assembly line. Chemical manufacturing plants utilize our structural stainless steel pipe to transport components of products and manufacturing materials. Refineries and other similar facilities apply this kind of industrial tubing to transfer chemical compounds.

Apparently, corrosion resistance is the key requirement in these applications. We design and fabricate our industrial steel tube to highest levels of corrosion resistance, as well as safety and health standards. Our process piping is available in various types to cater to your exact needs. Tailor-made food transport tube is also provided in accordance with your application requirements.

Sizes of Process Piping| Type | O.D. (mm) | W.T. (mm) |

| Welded Pipe | 6.0-3000 | 0.5-80.0 |

| Seamless Pipe | 6.0-711 | 0.5-50 |

Grades of Process Piping

TP304, TP304L, TP316, TP316L, TP316Ti, TP316LN, TP317, TP317L, TP321, TP310S, UNS, S32001, S32304, S31500, S31803 (S32205), S32750, S32760

Standards of Process Piping

GB/T14975-2002

Stainless Steel Seamless Tubes for Structures

GB/T14976-2002

Stainless Steel Seamless Tubes for Fluid Transport

GB12770-2002

Stainless Steel Welded Pipe for Structures

GB/T12771-2000

Welded Stainless Steel Pipes for Liquid Delivery

ASTM A312

Standard Specification for Seamless and Welded Austenitic Stainless Steel Pipes

ASTM A358

Electric Fusion Welded Austenitic Pipe for Corrosive and/or High Temperature Service

ASTM A790

Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

ASTM A928

Standard Specification for Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded with Addition of Filler Metal

Links:https://www.globefindpro.com/products/73445.html

-

Street Lights (70W-250W, XLD-L016B)

Street Lights (70W-250W, XLD-L016B)

-

Street Lights (70W-400W, with Stainless Steel Fasteners)

Street Lights (70W-400W, with Stainless Steel Fasteners)

-

Street Light Poles (Square Poles)

Street Light Poles (Square Poles)

-

Straight Tee

Straight Tee

-

Bollard Lights

Bollard Lights

-

Street Light Poles (Mid Hinged Poles)

Street Light Poles (Mid Hinged Poles)

-

Boiler Tube

Boiler Tube

-

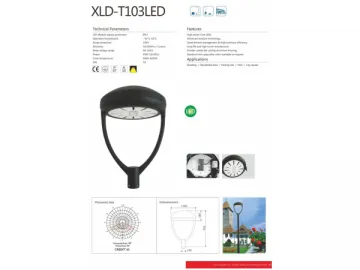

LED Post Light

LED Post Light

-

Finned Tubes

Finned Tubes

-

LED Light Module (Street Light Module)

LED Light Module (Street Light Module)

-

Custom Molded Rubber Parts

Custom Molded Rubber Parts

-

Molded Rubber Parts (Industrial Components)

Molded Rubber Parts (Industrial Components)