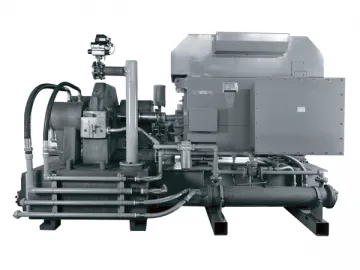

Heated Desiccant Air Dryer

The heated desiccant air dryer can either regenerate heat or regenerate no heat. It can employ micro heating to the generated air to reduce the consumption and save energy. When compared with the heatless adsorption dryer, the heated desiccant air dryer has reasonable switching time, less loss of regenerated air and more efficient electric energy conservation.

The regenerative desiccant dryer is currently the most economical and energy-efficient compressed air dryer in the purification industry. Our heated desiccant air dryer can be also widely applied to a variety of industries, such as metallurgy, electric power, electronics, food, chemical, petroleum, pharmaceutical, textile, tobacco, instrumentation, automation, etc.

Heated Desiccant Air Dryer’s Working Conditions and Technical Specifications

Regeneration: micro-thermal regeneration

Pressure dew point: Standard -40°C (-70°C Available)

Inlet temperature: 20°C-45°C

Working pressure: 0.6 Mpa-1.0Mpa

Desiccant: Activated alumina (As to regenerative dryers with low dew point, the desiccant is the combination of activated alumina and 5A molecular sieve.)

Working: The two desiccant cylinders work alternately and continuously.

Control: automatic microcomputer control

Electric heater voltage: 220V for 1Nm³/min -6Nm³/min; 380V for 8 Nm³/min and above

Oil content of air intake: ≤ 0.1PPM

Pressure loss: ≤ 0.02 Mpa

Regenerated air: ≤ 7%

Cycle: T = 2-6 (h)

Installation: indoors, no foundation (It has no special requirements of the ground.)

| Types | Air Handling Capacity (Nm3/min) | Heating Power (kw) | Desiccant Weight (kg) |

| FHWR-L-1 | 1.2 | 0.5 | 20 |

| FHWR-L-2 | 2.5 | 1 | 40 |

| FHWR-L-3 | 3.6 | 1.2 | 60 |

| FHWR-L-4.5 | 5 | 1.5 | 100 |

| FHWR-L-6 | 6.8 | 2.1 | 120 |

| FHWR-L-8 | 8.5 | 3 | 160 |

| FHWR-L-10 | 10.9 | 4 | 190 |

| FHWR-L-12 | 12.8 | 5 | 190 |

| FHWR-L-15 | 16 | 5 | 300 |

| FHWR-L-20 | 22 | 6 | 400 |

| FHWR-L-25 | 26.8 | 8 | 500 |

| FHWR-L-30 | 32 | 10 | 600 |

| FHWR-L-40 | 43.5 | 12 | 800 |

| FHWR-L-50 | 53 | 15 | 1,000 |

| FHWR-L-60 | 67 | 18 | 1,200 |

| FHWR-L-80 | 90 | 27 | 1,600 |

| FHWR-L-100 | 110 | 36 | 2,000 |

| FHWR-L-130 | 140 | 42 | 2,600 |

| FHWR-L-150 | 160 | 54 | 3,000 |

| FHWR-L-180 | 190 | 64 | 3,600 |

| FHWR-L-200 | 210 | 72 | 4,000 |

| FHWR-L-250 | 260 | 80 | 5,000 |

| FHWR-L-300 | 310 | 90 | 6,000 |

| FHWR-L-400 | 410 | 130 | 8,000 |

| FHWR-L-500 | 510 | 180 | 10,000 |

Links:https://www.globefindpro.com/products/73576.html

-

Water Cooled Single Screw Compressor

Water Cooled Single Screw Compressor

-

A Series Piston Air Compressor

A Series Piston Air Compressor

-

Heatless Desiccant Air Dryer

Heatless Desiccant Air Dryer

-

Air Oil Separator Element

Air Oil Separator Element

-

Off-road Dump Truck (Model GKM50C Mining Truck)

Off-road Dump Truck (Model GKM50C Mining Truck)

-

Centrifugal Water Separator

Centrifugal Water Separator

-

Hand Held Rock Drill

Hand Held Rock Drill

-

Deodorizing Filter

Deodorizing Filter

-

Centrifugal Air Compressor

Centrifugal Air Compressor

-

Air Cooled Single Screw Compressor

Air Cooled Single Screw Compressor

-

S Series Piston Air Compressor

S Series Piston Air Compressor

-

Water Cooled Twin Screw Compressor

Water Cooled Twin Screw Compressor