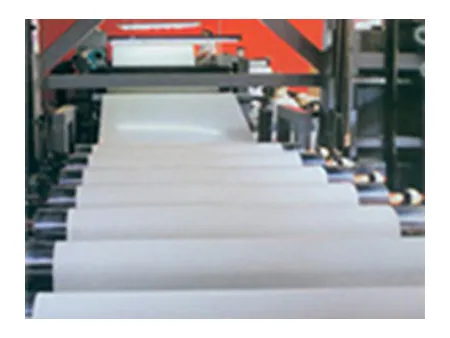

Hot Feed Rubber Strainer, DRLW Series

Rubber extruder with gear pump for filtering contaminants from rubber compounds  Specification

Specification

Advantages Gear pumps can be operated with a single drive or dual drive system.

The hot feed rubber strainer is utilized to cut the normal temperature strip rubber compound into the customer's desired shape and weight continuously. The weight accuracy of the rubber blank is monitored to within ±1% via the control of a gear pump.

Quick product setup with PLC control and process parameters database.

A separation structure using an electric motor supports the gear pump, screw and machine head, simplifying rubber raw material replacement and conducting easier cleaning.

Low temperature increase prevents scorching. Sulfur can be utilized optionally to avoid any potential risks. Error alarm with an icon displaying fault location.

The searchlight is a useful tool for cleaning, helping to ensure that all those tricky, hard to reach spots don't get overlooked.

Both system and extrusion pressures are intuitively displayed on the touch screen.

When creating a prototype of a new product, having a PLC in operation provides useful data that can be used to streamline the process.

The hot feed rubber strainer is a machine specially designed to remove contamination, such as iron scrap and sawdust, from rubber. This equipment works by feeding the material in the form of balls or strips into a screw and gear pump, then into the strainer. Not only rubber compounds, but it is also suitable for filtering a variety of products, including miscellaneous rubber parts, seals, vehicle components, oil seals, and more. Due to its versatility and efficacy, this type of filter is widely used in manufacturing processes for the previously mentioned products.

| Items | Unit | DRL150W | DRL200W | DRL250W |

| Screw diameter | mm | 150 | 200 | 250 |

| Screw L/D ratio | L/D | 6:1 | 6:1 | 5.4:1 |

| Screw rotation speed | Rpm | 0-40 | 0-40 | 0-40 |

| Speed of gear pump | Rpm | 0-40 | 0-40 | 0-40 |

| Cutter speed | KW | 50 | 70 | 105 |

| Total power | MPa | 35 | 35 | 35 |

| Max capacity (depending on mesh) | °C | 20-90 | 20-90 | 20-90 |

| External dimension (L*W*H) | kg/h | 750 | 1200 | 1800 |

| Weight | m | 3.5×1.9×2.2 | 3.8×1.9×2.2 | 4.0×1.9×2.2 |

| Feeding type | t | 7.5 | 10.5 | 13.5 |

| Max. mesh | Cold/Hot | Hot | Hot | Hot |

| Max capacity (depending on mesh) | mesh | 300 | 300 | 300 |

The hot feed rubber strainer is utilized to cut the normal temperature strip rubber compound into the customer's desired shape and weight continuously. The weight accuracy of the rubber blank is monitored to within ±1% via the control of a gear pump.

Quick product setup with PLC control and process parameters database.

A separation structure using an electric motor supports the gear pump, screw and machine head, simplifying rubber raw material replacement and conducting easier cleaning.

Low temperature increase prevents scorching. Sulfur can be utilized optionally to avoid any potential risks. Error alarm with an icon displaying fault location.

The searchlight is a useful tool for cleaning, helping to ensure that all those tricky, hard to reach spots don't get overlooked.

Both system and extrusion pressures are intuitively displayed on the touch screen.

When creating a prototype of a new product, having a PLC in operation provides useful data that can be used to streamline the process.

Scan QR to Read

Links:https://www.globefindpro.com/products/737.html

Links:https://www.globefindpro.com/products/737.html

Recommended Products

-

Rubber Ram Extruder, JYZ Series

Rubber Ram Extruder, JYZ Series

-

Cross Bonding Link Box

Cross Bonding Link Box

-

PVDF Coated Alumnium Foil Coil

PVDF Coated Alumnium Foil Coil

-

Water Cooling Conveyor, LSS Series

Water Cooling Conveyor, LSS Series

-

Outdoor Composite Cable Termination, 72.5kV-252kV

Outdoor Composite Cable Termination, 72.5kV-252kV

-

Dry Plug-in GIS Termination, 72.5kV-252kV

Dry Plug-in GIS Termination, 72.5kV-252kV

-

Universal Suction Cup Mount, UBA-GP/GPB/GPL/GPLB

Universal Suction Cup Mount, UBA-GP/GPB/GPL/GPLB

-

Hydraulic Butt Fusion Machine, WP1600AH

Hydraulic Butt Fusion Machine, WP1600AH

-

Copper Lug (with barrier), DTM Series

Copper Lug (with barrier), DTM Series

-

Suction Cup Phone Mount, UBA-01/01B/01L/01LB

Suction Cup Phone Mount, UBA-01/01B/01L/01LB

-

Suction Cup Tablet Mount, UBA-P1/P1L/P1B/P1LB

Suction Cup Tablet Mount, UBA-P1/P1L/P1B/P1LB

-

Constant Force Spring

Constant Force Spring

Hot Products