QT10-15 Automatic Block Making Machine

Designed to serve block suppliers in the Middle East and South America, QT10-15 automated block making machine gives an output of 20,000 blocks per day. For customers who go for high productivity and cost-performance ratio, this economical block machine model might be one of your best bets. Model QT10-15 block making machine brings together multiple desirable features commonly found in separate models into one unit.

Design

The brick machine design should enable high product quality and productivity. With an enhanced production ability, the state-of-the-art automatic block making machine design also enables a giant improvement in brick quality.

Safety

Each part design and technology has been proved by technical experts to ensure its safety performance far exceeds expectations.

Benefits

Exceptional quality, large productivity, high adaptability, great product variety

Techniques

Machine fault diagnosis, remote control

Control System

User-friendly intelligent interface, easy operation, Schneider electrical controls

| Brick Specifications | BrickSamples | pcs/mold | pcs/h | pcs/8h | 1 year (300 days) |

| Blocks 390×190×190mm 71pcs/m3 | 10 | 1800 | 14400 | 60845m3 | |

| Blocks 390×100×190mm 135pcs/m3 | 18 | 3240 | 25920 | 57600m3 | |

| Dutch Bricks 200×100×60mm 50pcs/m2 | 35 | 6300 | 50400 | 302400m2 | |

| Dog-Bone Paves 200×165×60mm 30pcs/m2 | 18 | 3240 | 25920 | 256634m2 | |

| Zigzag Pavers 225×112.5×60mm 40pcs/m2 | 24 | 4320 | 34560 | 262481m2 | |

| Perforated Bricks 240x115x90 402pcs/m3 | 24 | 4320 | 34560 | 10.36 million pcs | |

| Solid Bricks 240x115x53 683pcs/m3 | 48 | 8640 | 69120 | 20.73 million pcs |

| Dimension | 6900×5100×2900(mm) |

| Size of Pallet | 1100×850×25(bamboo plywood) |

| Weight | 12100kg |

| Vibration Frequency | 50-90Hz |

| Maximum Excitation Force | 120KN |

| Molding Cycle | 15-20S |

| Installed Capacity | 42KW |

Links:https://www.globefindpro.com/products/73867.html

-

QT9-15E Automatic Block Making Machine

QT9-15E Automatic Block Making Machine

-

QT4-15 Automatic Block Making Machine

QT4-15 Automatic Block Making Machine

-

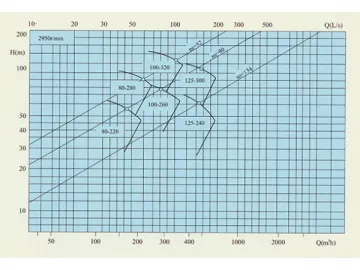

YYW Series Centrifugal Pump

YYW Series Centrifugal Pump

-

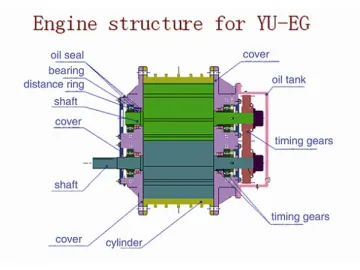

YU-EG Explosion Proof Three-lobe Roots Blower

YU-EG Explosion Proof Three-lobe Roots Blower

-

Fully Automatic Concrete Block Production Line with Rack

Fully Automatic Concrete Block Production Line with Rack

-

Concrete Tile Forming Machine

Concrete Tile Forming Machine

-

Y50 Series Circular Connectors

Y50 Series Circular Connectors

-

BZ Three-lobe Roots Blower

BZ Three-lobe Roots Blower

-

QT9-15 Automatic Block Making Machine

QT9-15 Automatic Block Making Machine

-

YYO,YYOW Single-stage Double-suction Centrifugal Pump

YYO,YYOW Single-stage Double-suction Centrifugal Pump

-

Simple Concrete Block Production Line

Simple Concrete Block Production Line

-

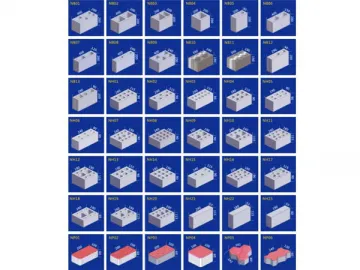

Concrete Block Sample

Concrete Block Sample