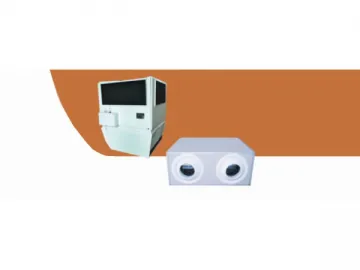

HASC2 Series High Static Pressure Ducted Unit

Features of High Static Pressure Ducted Unit

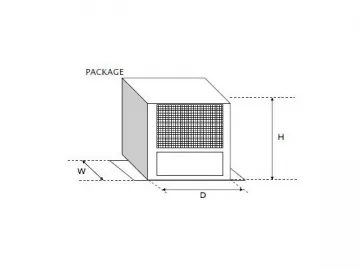

1. This high static pressure ducted unit enjoys a laconic structure, smaller volume and installation space;

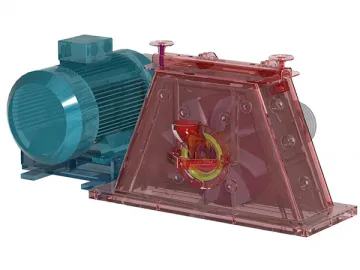

2. This high static pressure ducted cooler is quipped with cold rolled metal panels which, treated by electrostatic spray, highly resistant to corrosion;

3.Its hydrophilic aluminum fin cooper tube heat exchanger enjoys quite long mechanical lifespan;

4.With an efficient centrifugal fan, this high static pressure aircon enjoys quite low noise;

5.This commercial air conditioning equipment is quite easy to maintain;

6.Its large fully-weld condensate pan could effectively prevent leakage of condensate water;

7.This multifunctional cooling equipment is also equipped with a 24V thermostatic controller with large-sized LCD display.

Functions of High Static Pressure Ducted Unit

This high static pressure ducted unit employs air supply ducts which are installed behind the ceiling together with the indoor unit. By this installation method, this commercial high static pressure aircon, just like the central air conditioner, not only makes room more tidy by being hidden behind, but also cool multiple rooms at the same time. It allows users to decide the number of air outlets and their locations. More importantly, this cooling equipment could effectively regulate indoor temperature and bring fresh air into rooms. Especially, its filters could ensure the indoor air fresh and wholesome.

Advantages of High Static Pressure Ducted Unit

This smaller-size ducted A/C equipment enjoys not only the advantageous features of central air conditioner-convenient installation, laconic structure and artistic appearance, but also smaller installation space, multiple functions, environment friendliness and low energy consumption-all of which satisfy the requirements of modern indoor decoration and healthy life. Moreover, though providing fresh air in a uniform and genial way, it could effectively mitigate the sick building symptoms. Given the above fact, this high static pressure ducted air conditioner has become one of the most common used air conditioning apparatuses for the modern buildings.

Application of High Static Pressure Ducted Unit

This reliable ducted air conditioner, enjoying a split structure and a novel way of air supply by ducts, is quite applicable to such commercial and private occasions as office buildings, hotels, restaurants, shopping malls, factory floor, villas and apartments.

Technical Specifications of High Static Pressure Ducted Unit-R22

| Model | HASC2- | 80 | 140 | 170 | 220 | 250 | 300 | 350 |

| Condensing unit model | HASC2- | 80H | 140H | 170H | 220H | 250H | 300H | 350H |

| Cooling capacity | kW | 8.1 | 14.1 | 16.8 | 23.6 | 26.5 | 30.6 | 36.1 |

| Cooling power | kW | 2.91 | 5.1 | 5.9 | 8.3 | 9.4 | 10.7 | 12.4 |

| Heating capacity(optional) | kW | 8.5 | 14.6 | 17.8 | 24.8 | 27.8 | 31.5 | 37.8 |

| Heating power | kW | 2.76 | 4.85 | 5.61 | 7.89 | 8.93 | 10.17 | 11.78 |

| Electrical heater | kW | 3 | 4.5 | 6 | 8 | 8 | 12 | 12 |

| Power | 380V~415V 3Ph 50Hz | |||||||

| Fan type | Centrifugal type | |||||||

| Fan Q'ty | pcs | 1 | 1 | 2 | 2 | 2 | 1 | 1 |

| Air flow | m3/h | 1500 | 2400 | 3200 | 4600 | 5200 | 1 | 7200 |

| ESP | Pa | 60 | 150 | 150 | 200 | 200 | 1 | 300 |

| Control type | PCB | |||||||

| Air filter | G1-G4 cleanable type | |||||||

| Condensate pipe size | in | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ3/4 |

| Liquid pipe size | in | φ3/8" | φ1/2" | φ1/2" | φ1/2*2 | φ1/2*2 | φ1/2*2 | φ5/8 |

| Gas pipe size | in | φ5/8" | φ3/4" | φ3/4" | φ3/4*2 | φ3/4*2 | φ3/4*2 | φ1-3/8 |

| Noise | dB(A) | 53 | 60 | 66 | 66 | 66 | 68 | 68 |

| Model | HASC2- | 450 | 500 | 600 | 700 | 900 | 1000 |

| Condensing unit model | HASC2- | 450H | 500H | 600H | 700H | 900H | 1000H |

| Cooling capacity | kW | 46.6 | 52 | 61 | 72 | 93 | 104 |

| Cooling power | kW | 16.6 | 18.8 | 21.4 | 24.8 | 33.2 | 37.6 |

| Heating capacity(optional) | kW | 48.2 | 53.9 | 63 | 74.7 | 96.1 | 107 |

| Heating power | kW | 15.77 | 17.86 | 20.33 | 23.56 | 31.54 | 35.72 |

| Electrical heater | kW | 13.5 | 13.5 | 15 | 18 | 24 | 27 |

| Power | 380V~415V 3Ph 50Hz | ||||||

| Fan type | Centrifugal type | ||||||

| Fan Q'ty | pcs | 1 | 1 | 2 | 2 | 2 | 2 |

| Air flow | m3/h | 8200 | 9600 | 11600 | 12800 | 16000 | 18000 |

| ESP | Pa | 400 | 400 | 500 | 500 | 600 | 600 |

| Control type | PCB | ||||||

| Air filter | G1-G4 cleanable type | ||||||

| Condensate pipe size | in | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ1 | φ1 |

| Liquid pipe size | in | φ5/8*2 | φ5/8*2 | φ5/8*2 | φ5/8*2 | φ5/8*2 | φ5/8*2 |

| Gas pipe size | in | (φ1-1/8)*2 | (φ1-1/8)*2 | (φ1-1/8)*2 | (φ1-3/8)*3 | (φ1-1/8)*4 | (φ1-1/8)*4 |

| Noise | dB(A) | 71 | 72 | 73 | 74 | 76 | 76 |

| Model | HASC2N | 80H | 140H | 170H | 220H | 250H | 300H | 350H |

| Condensing unit model | HAS1RN | 80H | 140H | 170H | 220H | 250H | 300H | 350H-S |

| Cooling capacity | kW | 8 | 14.1 | 16.6 | 22.6 | 24.5 | 29.9 | 34.9 |

| Cooling power | kW | 3.04 | 5.3 | 6.2 | 8.3 | 8.9 | 10.5 | 12.1 |

| Heating capacity(optional) | kW | 8.3 | 14.6 | 17.6 | 23.2 | 25.2 | 31.2 | 35.3 |

| Heating power | kW | 2.89 | 5.04 | 5.89 | 7.89 | 8.46 | 9.98 | 11.5 |

| Electrical heater | kW | 3 | 4.5 | 6 | 8 | 8 | 12 | 12 |

| Power | 380V~415V 3PH 50H | |||||||

| Fan type | Centrifugal type | |||||||

| Fan Q'ty | pcs | 1 | 1 | 2 | 2 | 2 | 1 | 1 |

| Air flow | m3/h | 1500 | 2400 | 3200 | 4600 | 5200 | 6400 | 7200 |

| ESP | Pa | 60 | 150 | 150 | 200 | 200 | 300 | 300 |

| Control type | PCB | |||||||

| Air filter | G1-G4 cleanable type | |||||||

| Condensate pipe size | in | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ3/4 |

| Liquid pipe size | in | φ3/8" | φ1/2" | φ1/2" | φ1/2*2 | φ1/2*2 | φ1/2*2 | φ5/8 |

| Gas pipe size | in | φ5/8" | φ3/4" | φ3/4" | φ3/4*2 | φ3/4*2 | φ3/4*2 | φ1-3/8 |

| Noise | dB(A) | 53 | 60 | 66 | 66 | 66 | 68 | 68 |

| Model | HASC2N | 450H | 500H | 600H | 700H | 900H | 1000H |

| Condensing unit model | HAS1RN | 220H-S*2 | 250H-S*2 | 300H-S*2 | 350H-S*2 | 220H-S*4 | 250H-S*4 |

| Cooling capacity | kW | 44.6 | 49 | 59.7 | 69.2 | 89.4 | 96.1 |

| Cooling power | kW | 16.6 | 17.8 | 21 | 24.2 | 33.2 | 35.6 |

| Heating capacity(optional) | kW | 46.2 | 50.5 | 61.1 | 72.3 | 91.6 | 99.2 |

| Heating power | kW | 15.77 | 16.91 | 19.95 | 22.99 | 31.54 | 33.82 |

| Electrical heater | kW | 13.5 | 13.5 | 15 | 18 | 24 | 27 |

| Power | 380V~415V 3PH 50H | ||||||

| Fan type | Centrifugal type | ||||||

| Fan Q'ty | pcs | 1 | 1 | 2 | 2 | 2 | 2 |

| Air flow | m3/h | 8200 | 9600 | 11600 | 12800 | 16000 | 18000 |

| ESP | Pa | 400 | 400 | 500 | 500 | 600 | 600 |

| Control type | PCB | ||||||

| Air filter | G1-G4 cleanable type | ||||||

| Condensate pipe size | in | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ1 | φ1 |

| Liquid pipe size | in | φ5/8*2 | φ5/8*2 | φ5/8*2 | φ5/8*2 | φ5/8*2 | φ5/8*2 |

| Gas pipe size | in | (φ1-1/8)*2 | (φ1-1/8)*2 | (φ1-1/8)*2 | (φ1-3/8)*3 | (φ1-1/8)*4 | (φ1-1/8)*4 |

| Noise | dB(A) | 71 | 72 | 73 | 74 | 76 | 76 |

| Model | HASC2M- | 80H | 140H | 170H | 220H | 250H | 300H | 350H |

| Condensing unit model | HAS1RM- | 80H | 140H | 170H | 220H | 250H | 300H | 350H-S |

| Cooling capacity | kW | 7.6 | 13.6 | 16.1 | 21.4 | 25.5 | 29.8 | 32.8 |

| Cooling power | kW | 3.01 | 5.4 | 6.2 | 7.98 | 9.52 | 11.07 | 12.1 |

| Heating capacity(optional) | kW | 7.9 | 14.3 | 17.1 | 22.6 | 27.2 | 30.8 | 34.5 |

| Heating power | kW | 2.925926 | 5.296296 | 6.218182 | 7.793103 | 9.37931 | 10.58419 | 11.77474 |

| Electrical heater | kW | 3 | 4.5 | 6 | 8 | 8 | 12 | 12 |

| Power | 380V~415V 3Ph 50Hz | |||||||

| Fan type | centrifugal type | |||||||

| Fan Q'ty | pcs | 1 | 2 | 2 | 1 | 1 | 1 | 1 |

| Air flow | m3 /h | 3200 | 5600 | 6400 | 9800 | 9800 | 11600 | 11600 |

| ESP | Pa | 60 | 150 | 150 | 200 | 200 | 300 | 300 |

| Control type | PCB | |||||||

| Air filter | G1-G4 cleanable type | |||||||

| Condensate pipe size | in | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ3/4 |

| Liquid pipe size | in | φ3/8" | φ1/2" | φ1/2" | φ1/2*2 | φ1/2*2 | φ1/2*2 | φ5/8 |

| Gas pipe size | in | φ5/8" | φ3/4" | φ3/4" | φ3/4*2 | φ3/4*2 | φ3/4*2 | φ1-3/8 |

| Noise | dB(A) | 53 | 60 | 66 | 66 | 66 | 68 | 68 |

| Model | HASC2M- | 450H | 500H | 600H | 700H | 900H | 1000H |

| Condensing unit model | HAS1RM- | 220H-S*2 | 250H-S*2 | 300H-S*2 | 350H-S*2 | 220H-S*4 | 250H-S*4 |

| Cooling capacity | kW | 42.7 | 50.3 | 59.5 | 65.3 | 83.2 | 100.1 |

| Cooling power | kW | 15.96 | 19.04 | 22.14 | 24.2 | 31.92 | 38.08 |

| Heating capacity(optional) | kW | 45.1 | 54.3 | 61.7 | 68.6 | 89.4 | 107.3 |

| Heating power | kW | 15.55172 | 18.72414 | 21.20275 | 23.41297 | 30.82759 | 36.87285 |

| Electrical heater | kW | 13.5 | 13.5 | 15 | 18 | 24 | 27 |

| Power | 380V~415V 3Ph 50Hz | ||||||

| Fan type | Centrifugal type | ||||||

| Fan Q'ty | pcs | 2 | 2 | 2 | 2 | 4 | 4 |

| Air flow | m3/h | 9800 | 9800 | 11600 | 11600 | 9800 | 9800 |

| ESP | Pa | 400 | 400 | 500 | 500 | 600 | 600 |

| Control type | PCB | ||||||

| Air filter | G1-G4 cleanable type | ||||||

| Condensate pipe size | in | φ3/4 | φ3/4 | φ3/4 | φ3/4 | φ1 | φ1 |

| Liquid pipe size | in | φ5/8*2 | φ5/8*2 | φ5/8*2 | φ5/8*2 | φ5/8*2 | φ5/8*2 |

| Gas pipe size | in | (φ1-1/8)*2 | (φ1-1/8)*2 | (φ1-1/8)*2 | (φ1-3/8)*3 | (φ1-1/8)*4 | (φ1-1/8)*4 |

| Noise | dB(A) | 71 | 72 | 73 | 74 | 76 | 76 |

Related Products

Links:https://www.globefindpro.com/products/73982.html

-

HAHUW Series Rooftop Packaged Air Conditioning Unit (Screw Compressor)

HAHUW Series Rooftop Packaged Air Conditioning Unit (Screw Compressor)

-

Valve Parts

Valve Parts

-

Cast Steel Shot

Cast Steel Shot

-

Pass-Through Monorail Blast Machine

Pass-Through Monorail Blast Machine

-

Roller Conveyor Shot Blast Machine for H Shaped Steel

Roller Conveyor Shot Blast Machine for H Shaped Steel

-

Barrel Blast Machine

Barrel Blast Machine

-

Independent Electrical Control Panel for Crane Cab Air Conditioner

Independent Electrical Control Panel for Crane Cab Air Conditioner

-

HDGDS Series Long Distance Air Handling Unit

HDGDS Series Long Distance Air Handling Unit

-

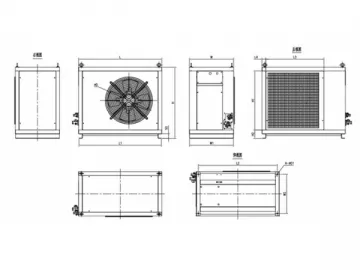

Condensing Unit for Crane Cab Air Conditioner

Condensing Unit for Crane Cab Air Conditioner

-

Split Floor Standing Crane Cab Air Conditioning Unit

Split Floor Standing Crane Cab Air Conditioning Unit

-

ZK Series Modular Air Handling Unit

ZK Series Modular Air Handling Unit

-

High-Performance Crane Cabin Air Conditioning Unit

High-Performance Crane Cabin Air Conditioning Unit