Cast Steel Shot

The cast steel shot is an effective abrasive media, and it is fabricated in accordance with the following standards.

1. GB/T18838.3-2008: Preparation of steel substrates before application of paints and related products - Specifications for metallic blast-cleaning abrasives - Part 3: High-carbon cast-steel shot and grit

2. SFSA Designation: 20-66

3. SAE J827: High Carbon Steel Shot

4. YB/T5149-93: Cast steel shot

5. MIL-S-851C: Military Specification: Steel Grit, Shot, And Cut Wire Shot; And Iron Grit And Shot-Blast Cleaning and Peening

6. ISO11124 Part 3: High-carbon cast-steel shot and grit

| Name | Cast steel shot | |

| Chemical composition | Carbon | 0.70~1.20% |

| Manganese | 0.35~1.20% | |

| Silicon | 0.40~1.20% | |

| Sulfur | ≤0.05% | |

| Phosphorous | ≤0.05% | |

| Average hardness (tested at the load of 500g) | Standard: 40~50HRC (377~509HV) Special: 52~56HRC (543~620HV) Special: 56~60HRC (620~713HV) | |

| Max. hardness deviation | ±3.0HRC (± 40HV) | |

| Microstructure | Uniform tempered martensite, or tempered troostite with well distributed carbides | |

| Min. density (alcohol replace testing) | 7.2g/cm3 | |

Application Range

This metal abrasive is developed for different purposes as listed below.

1. Surface cleaning: Castings, forgings, die-castings, steel plates, H-shaped steel, structural steel

2. Derusting and descaling: Castings, forgings, steel plates, H-shaped steel, structural steel

3. Surface strengthening: Gears, heat-treated parts

4. Shot blasting: Steel plates, steel profiles

5. Shot peening: Steel plates, steel profiles

6. Desanding: Steel plates, steel profiles

7. Pretreatment before painting: Steel plates, steel profiles, structural steel

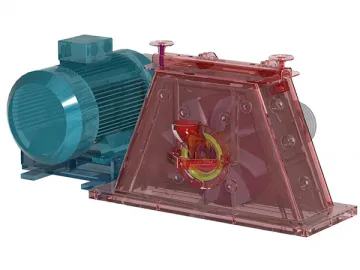

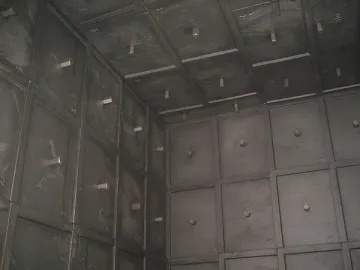

Applicable Equipment

As a kind of metallic blast cleaning abrasive, our cast steel shot is applicable for a wide range of shot blasting machine including barrel type, spinner hanger type, rubber belt type, pass-through type, turntable type, rotary table type, etc. It also works well with shot peening machine, steel plate pretreatment line and so on.

Size Distribution

| Screen No. | Screen size (mm) | Cast steel shot | ||||||||||

| SS-2.5 | SS-2.0 | SS-1.7 | SS-1.4 | SS-1.2 | SS-1.0 | SS-0.8 | SS-0.6 | SS-0.5 | SS-0.3 | SS-0.2 | ||

| 7 | 2.80 | all pass | ||||||||||

| 8 | 2.36 | all pass | ||||||||||

| 10 | 2.00 | 85% min | all pass | all pass | ||||||||

| 12 | 1.70 | 97% min | 85% min | 5% max | all pass | |||||||

| 14 | 1.40 | 97% min | 85% min | 5% max | all pass | |||||||

| 16 | 1.18 | 97% min | 85% min | 5% max | all pass | |||||||

| 18 | 1.00 | 96% min | 85% min | 5% max | all pass | |||||||

| 20 | 0.850 | 96% min | 85% min | 10% max | all pass | |||||||

| 25 | 0.710 | 96% min | 85% min | 10% max | ||||||||

| 30 | 0.600 | 96% min | 85% min | all pass | ||||||||

| 35 | 0.500 | 97% min | 85% min | 10% max | ||||||||

| 40 | 0.425 | 97% min | all pass | |||||||||

| 45 | 0.355 | 80% min | 10% max | |||||||||

| 50 | 0.300 | 90% min | ||||||||||

| 80 | 0.180 | 80% min | ||||||||||

| 120 | 0.125 | 90% min | ||||||||||

| 200 | 0.075 | |||||||||||

| 325 | 0.045 | |||||||||||

| SAE | S-780 | S-660 | S-550 | S-460 | S-390 | S-330 | S-280 | S-230 | S-170 | S-110 | S-70 | |

Packaging

Our cast steel shot is packaged in woven bags, paper bags, flexible freight bags, barrels or pallets.

Links:https://www.globefindpro.com/products/73991.html

-

Pass-Through Monorail Blast Machine

Pass-Through Monorail Blast Machine

-

Roller Conveyor Shot Blast Machine for H Shaped Steel

Roller Conveyor Shot Blast Machine for H Shaped Steel

-

Barrel Blast Machine

Barrel Blast Machine

-

Continuous Overhead Rail Shot Blast Machine

Continuous Overhead Rail Shot Blast Machine

-

Wire Mesh Belt Shot Blast Machine

Wire Mesh Belt Shot Blast Machine

-

Spinner Hanger Shot Blasting Machine

Spinner Hanger Shot Blasting Machine

-

Valve Parts

Valve Parts

-

HAHUW Series Rooftop Packaged Air Conditioning Unit (Screw Compressor)

HAHUW Series Rooftop Packaged Air Conditioning Unit (Screw Compressor)

-

HASC2 Series High Static Pressure Ducted Unit

HASC2 Series High Static Pressure Ducted Unit

-

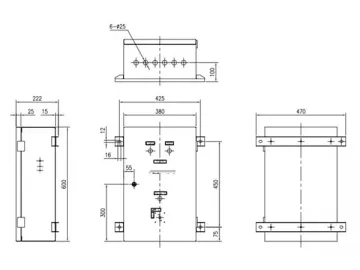

Independent Electrical Control Panel for Crane Cab Air Conditioner

Independent Electrical Control Panel for Crane Cab Air Conditioner

-

HDGDS Series Long Distance Air Handling Unit

HDGDS Series Long Distance Air Handling Unit

-

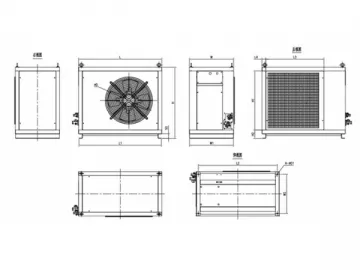

Condensing Unit for Crane Cab Air Conditioner

Condensing Unit for Crane Cab Air Conditioner