Pass-Through Monorail Blast Machine

The pass-through monorail blast machine is a batch type shot blasting machine used to remove sand, grit, rust, oxidized layer and other contaminants from small or medium sized castings, forgings and alloy parts, thus providing steel constructions with necessary pre-treatment before painting.

System Configuration

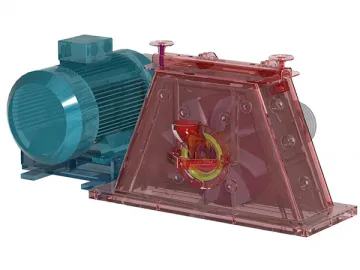

As an overhead monorail blast cleaning machine, our monorail blast machine is made up of several parts as demonstrated below.

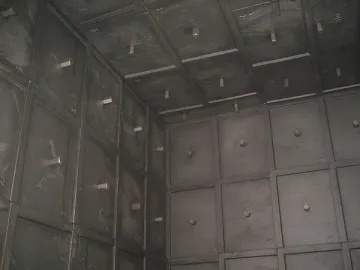

1. Blast Cabinet, Pre-Blastroom and Post-Blastroom

These parts are manufactured by welding structural steel frame with steel plates, and the blast cabinet is protected by wear resistant lining plates that are fixed by protective nuts for easy replacement. For pre-blastroom and post-blastroom which are connected directly before and after the pass-through monorail blast machine respectively, they are protected by wear resistant rubber plates, and two steel reinforced rubber plates are installed at the entrance to avoid abrasive splashing.

On one side wall of the blast cabinet, there are 4-6 blast wheel assemblies, and their positions and angles are determined by computer-aided 3D dynamic simulation. In this way, work pieces will receive thorough surface cleaning with minimized dead zone.

3. Abrasive Reclamation System

The abrasive reclamation system is made up of screw conveyor, bucket elevator, sand separator, pneumatic valve (for abrasive transport), abrasive delivery chute, etc.

4. Overhead Monorail

Our pass-through monorail blast machine uses overhead monorail to transfer work pieces to target workstations at a high speed, thus saving time and enhancing productivity. At the same time, fewer lifting tools are required, so the guide rail is released from heavy burden.

5. Other Parts

Aside from the above, this metal surface treatment equipment also contains dust removal system, start-up system and electrical control system.

Ordering Information

As a professional shot blasting machine producer and wholesaler in China, KAITAI could customize pass-through monorail blast machine in max. work piece size, number of blast wheel, number of workstation, size of shot blast cabinet and other aspects to best-fit every application.

| Item | Unit | Q583 | Q585 | Q5810 | Q588 |

| Max. work piece size | mm | Ф800×1500 | Ф800×1200 | Ф1300×2800 | Ф550×2200 |

| No. of workstations | - | 2 | 4 | 6 | 4 |

| No. of blast wheels | - | 4 | 6 | 6 | 4 |

| Abrasive consumption rate | kg/min | 4×250 | 6×360 | 6×330 | 4×480 |

| Power of blast wheels | kW | 4×15 | 6 ×22 | 6×22 | 4×22 |

| Max. loading capacity of hook | kg | 300 | 500 | 1000 | 800 |

| Productivity | Hook/hour | 40 | 55 | 50 | 30 |

| Blast cabinet size | mm | 3062×1800×2800 | 8500×1800×3885 | 8500×2300×4800 | 6800×2600×3325 |

| Air requirement | m3/h | 15000 | 18000 | 18000 | 17200 |

| Total power | kW | 74.5 | 186.85 | 186.85 | 121.05 |

Links:https://www.globefindpro.com/products/73992.html

-

Roller Conveyor Shot Blast Machine for H Shaped Steel

Roller Conveyor Shot Blast Machine for H Shaped Steel

-

Barrel Blast Machine

Barrel Blast Machine

-

Continuous Overhead Rail Shot Blast Machine

Continuous Overhead Rail Shot Blast Machine

-

Wire Mesh Belt Shot Blast Machine

Wire Mesh Belt Shot Blast Machine

-

Spinner Hanger Shot Blasting Machine

Spinner Hanger Shot Blasting Machine

-

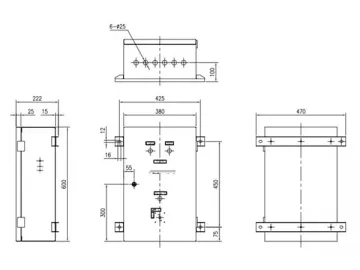

Shot Blasting Machine Parts

Shot Blasting Machine Parts

-

Cast Steel Shot

Cast Steel Shot

-

Valve Parts

Valve Parts

-

HAHUW Series Rooftop Packaged Air Conditioning Unit (Screw Compressor)

HAHUW Series Rooftop Packaged Air Conditioning Unit (Screw Compressor)

-

HASC2 Series High Static Pressure Ducted Unit

HASC2 Series High Static Pressure Ducted Unit

-

Independent Electrical Control Panel for Crane Cab Air Conditioner

Independent Electrical Control Panel for Crane Cab Air Conditioner

-

HDGDS Series Long Distance Air Handling Unit

HDGDS Series Long Distance Air Handling Unit