Electrical Parts

Are important electrical parts, and they can be customized in our factory if corresponding drawings are offered.

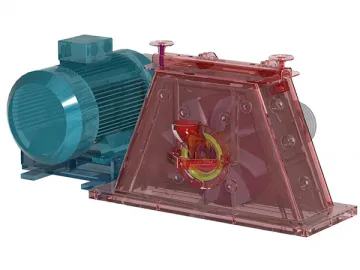

1. Inner Reducer Box Body

a. Manufacturing Technique: Combination of silica sol casting and water glass casting

b. Material: Cast steel (45#)

c. Tolerance: CT6

d. Surface roughness: Ra6.3

e. Performance: High hardness (HRC55 after tempering)

2. Impact Block

a. Manufacturing Technique: Combination of silica sol casting and water glass casting

b. Material: Cast steel (45#)

c. Tolerance: CT6

d. Surface roughness: Ra3.2

e. Performance: Good hardenability, excellent plasticity, no temper brittlement, suitable for welding and cutting

3. Brake Lever

a. Manufacturing Technique: Combination of silica sol casting and water glass casting

b. Material: Cast steel (45#)

c. Tolerance: CT6

d. Surface roughness: Ra3.2

e. Performance: Outstanding in strength, hardness and dimensional accuracy

4. Clutch Plate

a. Manufacturing Technique: Combination of silica sol casting and water glass casting

b. Material: Cast steel (45#)

c. Tolerance: CT6

d. Surface roughness: Ra3.2

e. Performance: Good plasticity, toughness and mechanical strength

5. Yoke Plate

a. Manufacturing Technique: Combination of silica sol casting and water glass casting

b. Material: Cast steel (45#)

c. Tolerance: CT6

d. Surface roughness: Ra3.2

e. Performance: Excellent mechanical property

6. Locking Pawl

a. Manufacturing Technique: Combination of silica sol casting and water glass casting

b. Material: Cast steel (45#)

c. Tolerance: CT6

d. Surface roughness: Ra3.2

e. Performance: Adjustable hardness (by tempering)

Links:https://www.globefindpro.com/products/74003.html

-

Agricultural Machinery Parts

Agricultural Machinery Parts

-

High Temperature Air Conditioning Unit

High Temperature Air Conditioning Unit

-

Shot Blasting Machine for Coil Springs

Shot Blasting Machine for Coil Springs

-

Rubber Belt Tumble Blast Machine

Rubber Belt Tumble Blast Machine

-

Rotary Table Shot Blast Machine

Rotary Table Shot Blast Machine

-

Construction Machinery Castings

Construction Machinery Castings

-

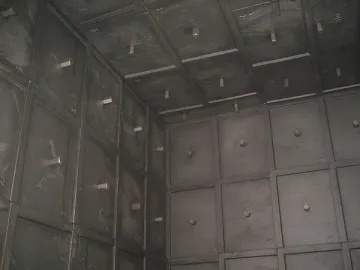

Shot Blasting Machine Parts

Shot Blasting Machine Parts

-

Spinner Hanger Shot Blasting Machine

Spinner Hanger Shot Blasting Machine

-

Wire Mesh Belt Shot Blast Machine

Wire Mesh Belt Shot Blast Machine

-

Continuous Overhead Rail Shot Blast Machine

Continuous Overhead Rail Shot Blast Machine

-

Barrel Blast Machine

Barrel Blast Machine

-

Roller Conveyor Shot Blast Machine for H Shaped Steel

Roller Conveyor Shot Blast Machine for H Shaped Steel