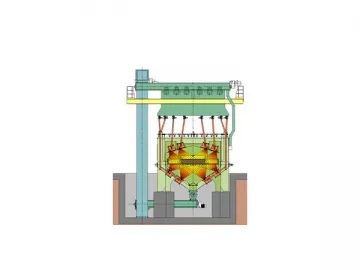

Rotary Table Shot Blast Machine

The rotary table shot blast machine uses blast wheels to accelerate abrasives, and then these high-speed abrasives are sprayed onto the surface of work piece which is loaded on the rotary table to remove sand, oxidized layer and other contaminants. As a result, metal parts will have glossy surfaces with a certain level of roughness.

System Configuration

Our table blast machine is a piece of cost effective metal surface cleaning equipment, and it can be divided into several major parts as listed below.

1. Blast Cabinet, Pre-Blastroom and Post-Blastroom

Our rotary table shot blast machine’s blast cabinet is manufactured by welding Q235 steel plate and profile steel, and it is internally lined with 10-mm-thick high chromium steel plates for better protection. These lining materials are connected together in an overlap manner and are fixed by special protective nuts so as to facilitate replacement when necessary.

As for the pre-blastroom and post-blastroom, they are constructed from steel plate and profile steel via welding process, and thick wear-resistant rubble plates are employed as their lining materials.

2. Blast Wheel Assembly

There are 2/4 blast wheel assemblies on the side walls of blast cabinet, and their positions and angles are calculated by 3D dynamic simulation to realize complete coverage. In addition, our blast wheel assembly is an integration of blast wheel, turbine, V-belt, belt pulley, bed plate and other components.

3. Abrasive Reclamation System

For our rotary table shot blast machine, its abrasive reclamation system is formed by belt conveyor, vibrating conveyor, bucket elevator, sand separator, abrasive silo, pneumatic valve, abrasive delivery chute and so on.

The work piece loading system is mainly composed of rotary table, perforated table plate, protective side plate, travelling wheel and drive mechanism, and the rotary table adopts a fully enclosed structure to protect speed reducer from being damaged by abrasives.

5. Dust Removal SystemThis wheel blast machine uses dust collector, blower, settling box and pipelines to create an effective dust removal system.

6. Electrical Control System

Our rotary table shot blast machine is controlled by a PLC controller, and there is a dedicated switch used to change between manual mode and automatic mode. More specifically, the automatic mode allows our shot blasting machine to work according to pre-programmed sequences, while the manual mode offers great convenience for operators when they need to make adjustments.

Thanks to the inter-locking, self-locking and failure warning functions, this high-speed shot blasting machine is able to work safely throughout its life span.

Ordering Information

Based on customers’ practical needs, our rotary table shot blast machine could be customized in several aspects, like max. work piece size, number of blast wheel, number of work station, size of blast cabinet, etc.

| Item | Unit | Q365C | Q3610 | Q3620 | Q765C | Q7610 | Q7620 | Q7630 |

| Max. work piece size | mm | 2500×1300 | 2500×1500×280 | 4000×3000×700 | 2500×1300 | 2500×1500×280 | 4000×3000×700 | 4000×2000 |

| Max. work piece weight | kg | 5000 | 10000 | 20000 | 5000 | 10000 | 20000 | 30000 |

| Abrasive consumption | kg/min | 2×260 | 4×250 | 4×250 | 2×260 | 4×250 | 4×250 | 4×250 |

| Loading capacity of elevator | t/h | 40 | 60 | 75 | 40 | 60 | 75 | 60 |

| Productivity of separator | t/h | 40 | 60 | 75 | 40 | 60 | 75 | 60 |

| Air requirement | m3/h | 13200 | 240000 | 21000 | 13200 | 240000 | 21000 | 21500 |

| Power (without dust removal system) | kW | 39.2 | 188.45 | 185.25 | 39.2 | 188.45 | 185.25 | 83.2 |

| Machine size (L×W×H) | mm | 9000×4200×9290 | 14900×5000×8700 | 16900×6450×10020 | 9000×4200×9290 | 14900×500×8700 | 16900×6450×10020 | 9168×7680×10874 |

Links:https://www.globefindpro.com/products/74012.html

-

Construction Machinery Castings

Construction Machinery Castings

-

Robotic Blasting Machine

Robotic Blasting Machine

-

Shot Blasting Machine for Pipes

Shot Blasting Machine for Pipes

-

Li-polymer Power Bank

Li-polymer Power Bank

-

Zinc Shot

Zinc Shot

-

Overhead Rail Shot Blast Machine

Overhead Rail Shot Blast Machine

-

Rubber Belt Tumble Blast Machine

Rubber Belt Tumble Blast Machine

-

Shot Blasting Machine for Coil Springs

Shot Blasting Machine for Coil Springs

-

High Temperature Air Conditioning Unit

High Temperature Air Conditioning Unit

-

Agricultural Machinery Parts

Agricultural Machinery Parts

-

Electrical Parts

Electrical Parts

-

Shot Blasting Machine Parts

Shot Blasting Machine Parts