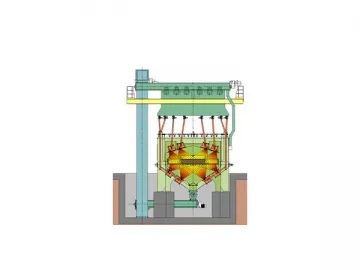

Robotic Blasting Machine

The robotic blasting machine is mainly composed of two parts: one is loading and unloading system, and the other is shot blasting system. In particular, its robotic arm is able to hold different sized and different shaped castings without changing clamps, and it offers remarkable cleaning result.

Feature and Application

1. Our robotic abrasive blasting unit takes advantage of a PLC to effectively control every processing step so as to satisfy diverse production needs, and this PLC also feeds back processing data to make sure that every movement of the robot is conducted in a precise and smooth manner, thus realizing repeatable working.

2. A user-friendly touch screen is equipped to our robotic blasting machine, and it not only offers controlling function, but also allows program modification, system monitoring and failure diagnosis.

3. This robot shot blasting machine provides a cost-effective surface preparation solution for cylinder block and cylinder head.

System Configuration

Our robotic blasting machine is an integration of the following parts.

1. Bucket elevator

2. Screw conveyor

3. Blast chamber

4. Blast wheel

5. Abrasive silo and distribution system

6. Separator

7. Rotary drum sieve

8. Dust removal system

9. Dust discharging chimney

10. Blower

11. Fastening mechanism, drive device and protection device for jack catch

Ordering Information

The robotic blasting machine could be tailored according to customer’s needs. For example, its max. work piece size, number of blast wheel, number of work station, size of blast cabinet and other parameters can be adjusted to best fit for every practical application.

| Item | Data |

| Max. work piece size (L×W×H) | 800×400×300mm |

| Max. work piece weight | 180kg |

| Productivity | 60 cycles per hour |

| Abrasive consumption rate | 1400kg/min |

| Air requirement | 13500m3/h |

| Total power | 115kW |

Links:https://www.globefindpro.com/products/74014.html

-

Shot Blasting Machine for Pipes

Shot Blasting Machine for Pipes

-

Li-polymer Power Bank

Li-polymer Power Bank

-

Zinc Shot

Zinc Shot

-

Overhead Rail Shot Blast Machine

Overhead Rail Shot Blast Machine

-

European Standard Plug Adapter

European Standard Plug Adapter

-

Aluminum Shot

Aluminum Shot

-

Construction Machinery Castings

Construction Machinery Castings

-

Rotary Table Shot Blast Machine

Rotary Table Shot Blast Machine

-

Rubber Belt Tumble Blast Machine

Rubber Belt Tumble Blast Machine

-

Shot Blasting Machine for Coil Springs

Shot Blasting Machine for Coil Springs

-

High Temperature Air Conditioning Unit

High Temperature Air Conditioning Unit

-

Agricultural Machinery Parts

Agricultural Machinery Parts