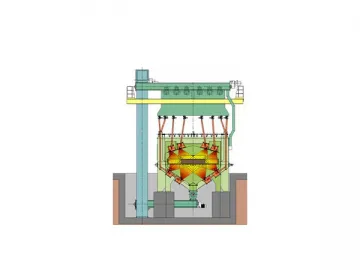

Overhead Rail Shot Blast Machine

The overhead rail shot blast machine is commonly used for desanding and descaling of castings by rotating workpiece carrying hooks at different points in the blast cabinet, so metal parts will regain their metallic luster.

Application

Our shot blasting machine is primarily used to deal with locomotive parts (swing bolster, side frame, coupler, coupler yoke, etc.), and it also fits for welded parts and small-sized components in batches.

System Configuration

As a piece of complicated metal surface cleaning equipment, the overhead rail shot blast machine is constituted of several parts.

The work piece transport system uses stamped and detachable heavy duty chains to lift work pieces, and the hook slideway at the top of blast cabinet adopts labyrinth seal formed by 10mm ZCr5 wear resistant plate, 8mm 65Mn steel plate, 4mm wear resistant rubber plate and nylon brush, so abrasives won’t be sprayed out the cabinet.

2. Blast Cabinet

The blast cabinet of this wheel blast machine is fabricated by welding steel plate and profile steel, and it is lined with 10-mm-thick ZCr5 wear resistant steel plates which are interchangeable and fixed by protective nuts. To achieve complete coverage, the cabinet shape, cabinet size, blast wheel location and blast wheel angle are all optimized by computer-aided dynamic simulation.

Our overhead rail shot blast machine has 6 blast wheel assemblies on the side wall of blast cabinet, and these blast wheel assemblies are composed of blast wheel, turbine, belt pulley, V-belt and other components. In addition, the applied Q130 blast wheel has one disc and several curved blades, and it is produced using PANGBORN technology.

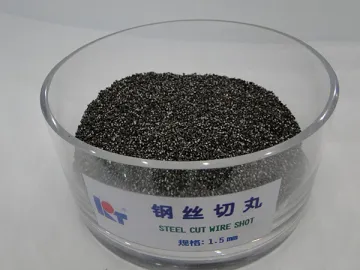

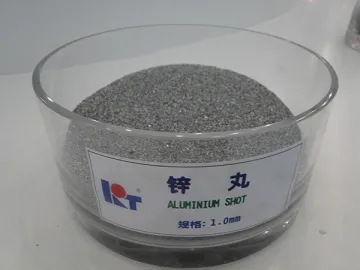

4. Abrasive Reclamation System

The abrasive reclamation system mainly contains screw conveyor, bucket elevator, sand separator, pneumatic valve (for abrasive transport), abrasive delivery chute, automatic compensation unit and so on.

5. Electrical Control System

Our overhead rail shot blast machine takes advantage of a PLC controller to realize centralized control, and both automatic control and manual control are available. Under automatic mode, this machine will work as regulated by predetermined program, while the manual mode facilitates testing and adjustment.

6. Other Parts

Aide from the abovementioned parts, there are some other components, such as rotation mechanism, dust removal system, etc.

| Item | Unit | Q383/Q483 | Q385/Q485 | Q4810 |

| Max. work piece size | mm | Ф800×1200 | Ф1000×1500 | Ф1000×2500 |

| No. of workstation | - | 2 | 2 | 6 |

| No. of blast wheel | kg | 4 | 4 | 6 |

| Abrasive consumption | kg/min | 4×250 | 4×250 | 6×250 |

| Power of blast wheels | kW | 4×15 | 4×15 | 6×15 |

| Max. load capacity of hook | kg | 300 | 500 | 1000 |

| Productivity | Hook/hour | 30~60 | 30~60 | 40~60 |

| Blast cabinet size | mm | 7680×2000×2900 | 7680×2000×2900 | 7680×2000×3800 |

| Air requirement | m3/h | 17000 | 19000 | 19000 |

| Total power | kW | 73.15 | 73.15 | 114.72 |

Links:https://www.globefindpro.com/products/74019.html