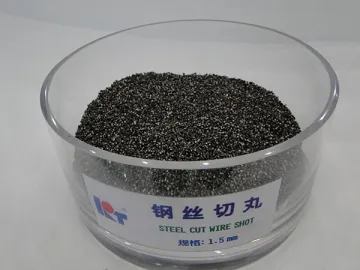

Steel Cut Wire Shot

The steel cut wire shot is a metal shot available in four different sizes which are 1.0mm, 1.5mm, 2.0mm and 2.5mm, and it is manufactured according to SAE J441 and JB/T 8354-1996 standards. However, this abrasive shot is made from recycled steel wire, so its length may be a little different from standard value.

Technical Data| Name | Steel cut wire shot | |

| Chemical composition | Carbon | 0.45~0.75% |

| Manganese | 0.40~1.20% | |

| Silicon | 0.10~0.30% | |

| Sulfur | <0.04% | |

| Phosphorous | <0.04% | |

| Average hardness | 1.0mm: 51~53HRC (525~561HV) 1.5mm: 41~45HRC (388~436HV) | |

| Max. hardness deviation | ±1.0HRC (±40HV) | |

| Tensile strength | 1.0mm: 1750~2150MPa 1.5mm: 1250~1450MPa | |

| Microstructure | Longitudinal: Uniformly deformed pearlite Transverse: Uniformly deformed pearlite | |

| Min. density (alcohol replace testing) | 7. 8g/cm3 | |

Application Range

Our steel cut wire shot suits for the following applications:

1. Surface cleaning: Castings, forgings, die-castings, steel plates, H-shaped steel, structural steel

2. Derusting and descaling: Castings, forgings, steel plates, H-shaped steel, structural steel

3. Surface strengthening: Gears, heat-treated parts

4. Shot blasting: Steel plates, steel profiles

5. Shot peening: Steel plates, steel profiles

6. Desanding: Steel plates, steel profiles

7. Pretreatment before painting: Steel plates, steel profiles, structural steel

Applicable Equipment

Our metal abrasive works well with shot blasting machine, shot peening machine, sand blasting machine, steel plate pretreatment line, etc.

Packaging

The steel cut wire shot is packed in woven bags, paper bags, flexible freight bags, barrels or pallets.

Links:https://www.globefindpro.com/products/74023.html