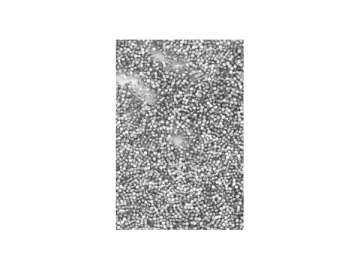

Stainless Steel Shot

The stainless steel shot is manufactured in strict compliance with SAE and JIS standards, and it is further divided into several models according to its size. Here are corresponding pictures.

0.3mm Stainless Steel Shot

0.4mm Stainless Steel Shot

0.5mm Stainless Steel Shot

0.6mm Stainless Steel Shot

0.8mm Stainless Steel Shot

Technical Data

| Name | Stainless steel shot | |

| Chemical composition | Carbon | ≤0.12% |

| Manganese | ≤2.00% | |

| Silicon | ≤1.00% | |

| Chrome | 17~19% | |

| Nickel | 7~10% | |

| Sulfur | ≤0.03% | |

| Phosphorous | ≤0.035% | |

| Average hardness | 41~59 HRC (388~509HV) | |

| Max. hardness deviation | ±1.0HRC (±40HV) | |

| Microstructure | Longitudinal: Uniformly deformed austenite Transverse: Uniformly deformed austenite | |

| Min. density | 7. 8g/cm3 | |

Note: Other chemical compositions are provided upon request, like

1. 304 Austenite Type Stainless Steel Shot

C: <0.15%

Cr: 16~18%

Ni: 6~10%

Si: <1%

Mn: <2%

2. 403 Ferrite Type Stainless Steel Shot

C: <0.15%

Cr: 16~18%

Si: <1%

Mn: <1%

3. 410 Martensite Type Stainless Steel Shot

C: <0.15%

Cr: 11~13%

Si: <1%

Mn: <1%

Application Range

Our stainless steel abrasive media have found a lot of applications as demonstrated below.

1. Surface cleaning: Castings, forgings, die-castings, steel plates, aluminum alloy, copper alloy, zinc alloy, magnesium alloy, stainless steel

2. Derusting and descaling: Castings, forgings, steel plates, H-shaped steel, structural steel

3. Surface strengthening: Stainless steel parts, heat treated parts

Applicable Equipment

This metal abrasive fits perfectly for shot blasting machine, shot peening machine, sand blasting machine, steel plate pretreatment line and so on.

Packaging

Our stainless steel shot is packed in woven bags, paper bags, flexible freight bags, barrels or pallets.

Links:https://www.globefindpro.com/products/74024.html