Cast Steel Grit

The cast steel grit is classified into 10 models which are G10, G12, G14, G16, G18, G25, G40, G50, G80 and G120.

G10 Cast Steel Grit

G12 Cast Steel Grit

G14 Cast Steel Grit

G16 Cast Steel Grit

G18 Cast Steel Grit

G25 Cast Steel Grit

G40 Cast Steel Grit

G50 Cast Steel Grit

G80 Cast Steel Grit

G120 Cast Steel Grit

Production Standard for Cast Steel Grit

1. GB/T18838.3-2008: Preparation of steel substrates before application of paints and related products - Specifications for metallic blast-cleaning abrasives - Part 3: High-carbon cast-steel shot and grit

2. SFSA Designation: 20-66

3. SAE J1993: High Carbon Steel Grit

4. YB/T5150-1993: Cast steel grit

5. MIL-S-851C: Military Specification: Steel Grit, Shot, And Cut Wire Shot; And Iron Grit And Shot-Blast Cleaning and Peening

6. ISO11124 Part 3: High-carbon cast-steel shot and grit

| Name | Cast steel grit | |

| Chemical composition | Carbon | 0.70~1.20% |

| Manganese | 0.35~1.20% | |

| Silicon | 0.40~1.20% | |

| Sulfur | ≤0.05% | |

| Phosphorous | ≤0.05% | |

| Average hardness (tested at the load of 500g) | GP steel grit: 42~50HRC (399~509HV) GL steel grit: 56~60HRC (620~713HV) GH steel grit: 63~66HRC (759~889HV) | |

| Max. hardness deviation | ±3.0HRC (± 40HV) | |

| Microstructure | Uniform tempered martensite, or tempered troostite with well distributed carbides | |

| Min. density (alcohol replace testing) | 7.4g/cm3 | |

Application Range

This cast steel abrasive is intended for a wide range of jobs, such as:

1. Surface cleaning: Castings, forgings, die-castings, steel plates, H-shaped steel, structural steel

2. Derusting and descaling: Castings, forgings, steel plates, H-shaped steel, structural steel

3. Surface strengthening: Gears, heat-treated parts

4. Shot blasting: Steel plates, steel profiles

5. Shot peening: Steel plates, steel profiles

6. Desanding: Steel plates, steel profiles

7. Pretreatment before painting: Steel plates, steel profiles, structural steel

Detailed Application Information

1. GP Steel Grit

The GP steel grit is a kind of angular metal abrasive that will lose its sharpness during operation, and it is suited to remove mill scale from steel plates.

2. GL Steel Grit

The GL steel grit will also lost its sharpness during shot blasting though it has higher hardness when compared to GP steel grit, and it is particularly suitable for the descaling of steel plates.

3. GH Steel Grit

With a very high hardness level, the GH steel grit maintains its angularity during operation, and it offers an effective solution to create regular yet etched surface. This kind of cast steel grit is highly recommended when working performance is of top priority than price, like dealing with rollers for cold mills. In addition, this product is designed specifically for air blast operations.

Applicable Equipment

The cast steel grit fits for a number of metal surface treatment machines, like:

1. Barrel blast machine, overhead rail shot blast machine, rubber belt tumble blast machine, pass-through monorail blast machine, turntable shot blasting machine, spinner hanger shot blasting machine, rotary table shot blast machine, wire mesh belt shot blast machine, steel pipe shot blasting machine, coil spring shot blasting machine and other shot blasting equipment.

2. Shot peening machine, derusting equipment, steel plate pretreatment line

3. Sanding machine for aluminum alloy, zinc alloy and stainless steel

4. Specialized metal surface cleaning equipment for carbon rods, auto parts, motorcycle accessories, marine anchor chains, construction machinery, steel profiles, steel constructions, etc.

Size Distribution

| Screen No. | Screen size (mm) | Cast steel grit | |||||||||

| 2.5 | 2.0 | 1.7 | 1.4 | 1.2 | 1.0 | 0.7 | 0.4 | 0.3 | 0.2 | ||

| 7 | 2.80 | all pass | |||||||||

| 8 | 2.36 | all pass | |||||||||

| 10 | 2.00 | 80% min | all pass | ||||||||

| 12 | 1.70 | 90% min | 80% min | all pass | |||||||

| 13 | 1.40 | 90% min | 80% min | all pass | |||||||

| 16 | 1.18 | 90% min | 75% min | all pass | |||||||

| 18 | 1.00 | 85% min | 75% min | all pass | |||||||

| 20 | 0.850 | ||||||||||

| 25 | 0.710 | 85% min | 70% min | all pass | |||||||

| 30 | 0.600 | ||||||||||

| 35 | 0.500 | 80% min | |||||||||

| 40 | 0.425 | 70% min | all pass | ||||||||

| 45 | 0.355 | ||||||||||

| 50 | 0.300 | 80% min | 65% min | all pass | |||||||

| 80 | 0.180 | 75% min | 65% min | ||||||||

| 120 | 0.125 | 75% min | 60% min | ||||||||

| 200 | 0.075 | 70% min | |||||||||

| 325 | 0.045 | ||||||||||

| SAE | G-10 | G-12 | G-14 | G-16 | G-18 | G-25 | G-40 | G-50 | G-80 | G-120 | |

Packaging

Our cast steel grit is packed in woven bags, paper bags, flexible freight bags, barrels or pallets.

Links:https://www.globefindpro.com/products/74041.html

-

Cone Crusher(40-340 Ton per hour)

Cone Crusher(40-340 Ton per hour)

-

Universal Vertical Socket

Universal Vertical Socket

-

Australian Standard Plug Adapter

Australian Standard Plug Adapter

-

Automotive Castings

Automotive Castings

-

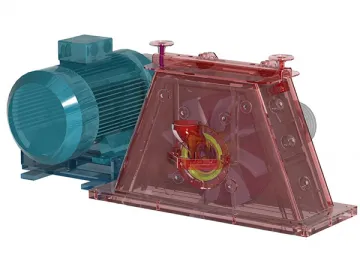

Turntable Shot Blasting Machine

Turntable Shot Blasting Machine

-

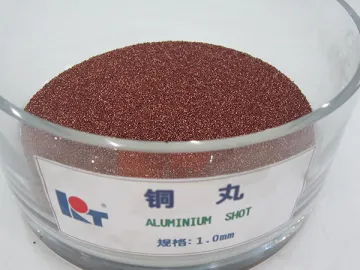

Copper Shot

Copper Shot

-

Shot Blasting Machine with Overhead Conveyor

Shot Blasting Machine with Overhead Conveyor

-

Cone Crusher(45-1270 Ton per hour)

Cone Crusher(45-1270 Ton per hour)

-

Vibrating Feeder(20-180 Ton per hour)

Vibrating Feeder(20-180 Ton per hour)

-

Belt Conveyor

Belt Conveyor

-

Vibrating Feeder(70-450 Ton per hour)

Vibrating Feeder(70-450 Ton per hour)

-

Shot Blasting Machine for Steel Sheets and Profiles

Shot Blasting Machine for Steel Sheets and Profiles