Concrete Mixing Plant

HZS series concrete mixing plant applies to building, bridge, water conservancy, airport, port and other large infrastructure projects and constructions with heavy demand for concrete supply. The features of our concrete mix design include detailed gradation, reasonable layout, compact structure, and high reliability. We have a total of 10 models of concrete mixing plants for customers to choose from, available in production capacity from 25m3/h-200 m3/h.

Features of Concrete Mixing Plant

l. The concrete batching plant adopts JS series twin-shaft compulsory concrete mixer, which boasts full and uniform mixing in high production efficiency.

2. The cement plant is controlled by a highly reliable industrial computer with simulation of the entire dynamic process presented on the interface, allowing real-time monitoring.

3. Equipped with electronic scale, PLC, dual display, and automatic monitoring system, the concrete mixing plant has functions of semi-automatic and automatic control, concrete mix ratio memory, automatic error compensation, data report printing, etc.

4. The fully enclosed mixing building greatly reduces dust and noise pollution on the environment.

Technical Parameters of Concrete Mixing Plant

| Model | HZS25 | HZS40 | HZS50 | HZS60 | HZS75 | HZS90 | HZS120 | HZS150 | HZS180 | HZS200 |

| Capacity (m3/h) | 25 | 40 | 5 0 | 60 | 75 | 90 | 120 | 150 | 180 | 200 |

| Mixing drum | JS500 | JS750 | JS1000 | JS1000 | JS1500 | JS1500 | JS2000 | JS3000 | JS3500 | JS4000 |

| Hopper capacity (m3) | 3×4 | 3×5 | 3× 7 | 3×12 | 3×12 | 3×16 | 4×14 | 4×20 | 4×20 | 4×25 |

| Max. aggregate diameter (Gravel / pebbles ) (mm) | 60/80 | 60/80 | 60/80 | 60/80 | 60/80 | 60/80 | 60/80 | 60/80 | 60/80 | 60/80 |

| Discharging height (m) | 1.7-3.8 | 1.7-3.8 | 3.8 | 3.8 | 4 | 4 | 4 | 4 | 4 | 4 |

| Feeding height (m) | 2.7 | 2.9 | 2.9 | 2.9 | 2.9 | 2.9 | 2.9 | 2.9 м | 2.9 | 2.9 |

| Aggregate measuring accuracy (%) | ±2 | ±2 | ±2 | ±2 | ±2 | ±2 | ±2 | ±2 | ±2 | ±2 |

| Cement measuring accuracy (%) | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

| Coal ash measuring accuracy (%) | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

| Water measuring accuracy (%) | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

| Additive measuring accuracy (%) | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

Control Room

Equipped with air conditioning, and PC / PLC for manual, semi-automatic, fully automatic control.

Mixing Tower

Modular design, decent appearance, easy installation and transitions.

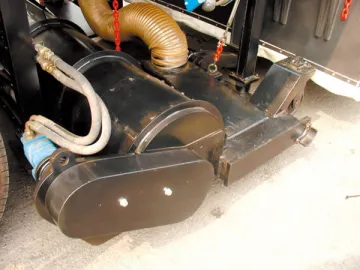

Mixer

Evenly mixing in short time, leaving no dead ends.

JRM is a professional construction equipment manufacturer. Welcome to contact us to find the best concrete equipment for making concrete materials.

Links:https://www.globefindpro.com/products/74124.html

-

Snow Removal Brush (Front Mounted Snow Brush)

Snow Removal Brush (Front Mounted Snow Brush)

-

Ice Removal Equipment

Ice Removal Equipment

-

Asphalt Batch Mix Plant (Model LB1000 Asphalt Mixing Plant)

Asphalt Batch Mix Plant (Model LB1000 Asphalt Mixing Plant)

-

Asphalt Batch Mix Plant (Model LB3250 Asphalt Mixing Plant)

Asphalt Batch Mix Plant (Model LB3250 Asphalt Mixing Plant)

-

Deicing Salt Spreader

Deicing Salt Spreader

-

Pavement Grooving Machine

Pavement Grooving Machine

-

Asphalt Batch Mix Plant (Model LB5000 Asphalt Plant)

Asphalt Batch Mix Plant (Model LB5000 Asphalt Plant)

-

Snow Removal and Deicing Truck

Snow Removal and Deicing Truck

-

Crack Sealing Truck

Crack Sealing Truck

-

Road Maintenance Truck (Hot Mix Asphalt Equipment)

Road Maintenance Truck (Hot Mix Asphalt Equipment)

-

Crack Sealing Machine (Self Propelled Crack Filler)

Crack Sealing Machine (Self Propelled Crack Filler)

-

Guardrail Cleaning Truck

Guardrail Cleaning Truck