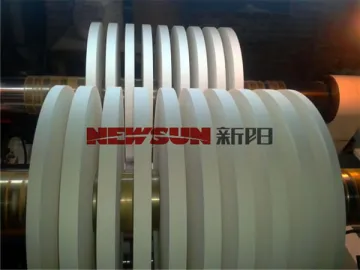

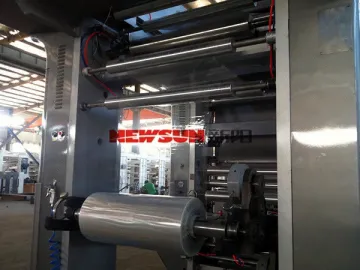

FHQR Series High-Speed Slitter Rewinder

The FHQR series high-speed slitter rewinder is highly intelligent roll material processing equipment. This paper slitting machine uses PLC to control electrical system. Touch screen is highly responsible for easy operation, fast configuration and parameter read-out. This slitter rewinder is your best choice on processing all kinds of roll materials such as BOPP, PET, CPP, PVC, PE, adhesive sticker and paper, etc.

Advantages

1. We adopt magnetic powder clutch to control unwinding and rewinding units. Roll diameter is automatically calculated by PLC, thus realizing automatic tension control.

2. In the unwinding unit, this slitter rewinder employs inflatable shaft for material discharge. Roll material is lifted by pneumatic system for outstanding efficiency and easy operation. Automatic guide system is available in unwinding unit.

3. Our thin film slitting equipment is fitted with dual slitting method that is the combination of razor blades and circular knives, thus offering remarkable efficiency. Moreover, air conveying system removes material waste in a holistic approach.

4. This adhesive sticker slitter comes with value-added functions such as calculation and counting, etc.

5. Our slitting and rewinding system is renowned for integrated combination of mechanical electrical hydraulic engineering. Comprehensive protection system is also available.

| Model | FHQR-1300 |

| Max. Web Width | 1300mm |

| Max. Unwinding Diameter | Φ800mm |

| Max. Machine Speed | 300m/min |

| Max. Rewinding Diameter | 500mm |

| Min. Web Width | 30mm |

| Accuracy | ±0.4mm |

| Machine Weight | 2600kg |

| Total Power | 6kW |

| Overall Dimension (L×W×H) | 2350×3600×1700mm |

Links:https://www.globefindpro.com/products/74279.html

-

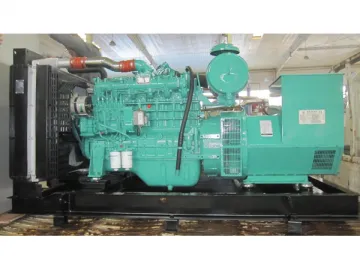

SDEC Diesel Generator Sets

SDEC Diesel Generator Sets

-

QDF Series High-Speed Dry Laminating Machine

QDF Series High-Speed Dry Laminating Machine

-

Yuchai Engines

Yuchai Engines

-

Yuchai Marine Generator Sets

Yuchai Marine Generator Sets

-

FHQZ Series High-Speed Slitting and Rewinding Machine

FHQZ Series High-Speed Slitting and Rewinding Machine

-

QDTJ-400B Series Hot Stamping Machine

QDTJ-400B Series Hot Stamping Machine

-

ZFJ Series Slitter Rewinder for Paper and Aluminum Foil

ZFJ Series Slitter Rewinder for Paper and Aluminum Foil

-

Yuchai Diesel Generator Sets

Yuchai Diesel Generator Sets

-

ASY-E Series High-Speed Rotogravure Printing Machine

ASY-E Series High-Speed Rotogravure Printing Machine

-

ASY-B Series Rotogravure Printing Machine

ASY-B Series Rotogravure Printing Machine

-

FHYB Series High-Speed Inspection Rewinder

FHYB Series High-Speed Inspection Rewinder

-

Cummins Marine Generator Sets

Cummins Marine Generator Sets