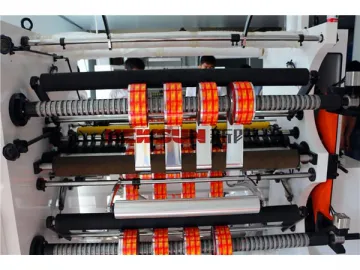

FHQZ Series High-Speed Slitting and Rewinding Machine

The FHQZ series high-speed slitting and rewinding machine is practically engineered for processing 25-120g/m2 paper, such as rolling paper, tipping paper, label paper and other decorative paper rolls, etc. This series of paper processing machinery accurately cuts single-layer rewinding into double layers, three layers or four layers. Slitting width and layer can be tailored to meet your exact needs.

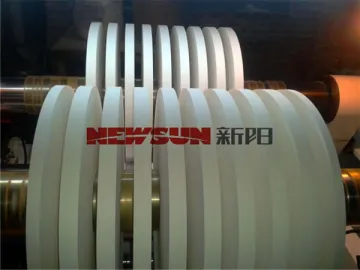

This high-speed slitting and rewinding machine is fitted with calender rolls which are made from top-ranking solid steel and specially treated. Thanks to these superior rolls, our paper roll slitter rewinder produces amazingly smooth bobbin with high quality. In addition, we also introduce several arc rollers to this bobbin slitting and rewinding system for ideal scattering effects. Synchronous belt drive is responsible for reliable performance and minimized noise at high speed operation.

Advantages

1. Electrical control system in this high-speed slitting and rewinding machine is equipped with imported PLC and touch screen, which allows for easy parameter configuration and intuitive display of operation status.

2. Main motor and unwinding shaft are controlled by frequency converter and is powered by variable frequency drive, thus achieving stable speed change.

3. Rewinding shaft is pneumatically controlled and rewinding process is powered by two servo motors. Tension is automatically controlled.

4. Unwinding unit involves the utilization of inflatable shaft and pneumatic drive, whereby customers benefit from easy operation and impressive efficiency. Unwinding process is automatically guided.

5. Our automatic slitting and rewinding equipment uses circular knives to precisely cut paper rolls and offers smooth bobbin. Air blowing device is available for waste collection.

6. This high-speed slitting and rewinding machine features value-added functions such as metering, diameter calculation and automatic shutdown, etc.

7. The well-conceived design is the comprehensive combination of mechanical, electrical and hydrualic systems, and features integrated protection measures.

| Model | FHQZ-800 | FHQZ-1000 | FHQZ-1200 |

| Max. Web Width | 800mm | 1000mm | 1200mm |

| Max. Unwinding Diameter | 800mm | 800mm | 800mm |

| Max. Machine Speed | 400m/min | 400m/min | 400m/min |

| Max. Rewinding Diameter | 500mm | 500mm | 500mm |

| Min. Web Width | 36mm | 36mm | 36mm |

| Machine Weight | 3200kg | 3500kg | 3800kg |

| Total Power | 20kW | 24kW | 28kW |

| Overall Dimension (L×W×H) | 3000×2300×1500mm | 3000×2500×1500mm | 3000×2700×1500mm |

Links:https://www.globefindpro.com/products/74284.html

-

QDTJ-400B Series Hot Stamping Machine

QDTJ-400B Series Hot Stamping Machine

-

FHQJ Series High-Speed Slitter Rewinder

FHQJ Series High-Speed Slitter Rewinder

-

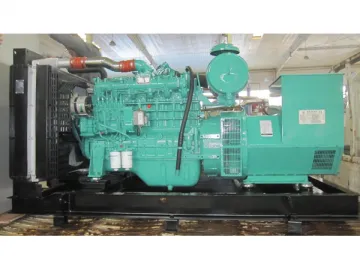

Cummins Engines

Cummins Engines

-

Accessories

Accessories

-

ASYQD-E Series Rotogravure Printing Machine

ASYQD-E Series Rotogravure Printing Machine

-

FHQB Series High-Speed Slitter Rewinder

FHQB Series High-Speed Slitter Rewinder

-

Yuchai Marine Generator Sets

Yuchai Marine Generator Sets

-

Yuchai Engines

Yuchai Engines

-

QDF Series High-Speed Dry Laminating Machine

QDF Series High-Speed Dry Laminating Machine

-

SDEC Diesel Generator Sets

SDEC Diesel Generator Sets

-

FHQR Series High-Speed Slitter Rewinder

FHQR Series High-Speed Slitter Rewinder

-

ZFJ Series Slitter Rewinder for Paper and Aluminum Foil

ZFJ Series Slitter Rewinder for Paper and Aluminum Foil