Tungsten Carbide Welding Rods

Because of the superior performance of the raw material, our tungsten carbide welding rod offers higher hardness and wear resistance than other types of welding supplies. Adopting the tungsten carbide as the hard phase, the tubular electrode is compatible with oxy-acetylene welding and electrogas welding methods.

As a kind of multifunctional tungsten carbide rod, our tungsten carbide welding rod is the best selection of welding electrodes for surfacing and repairing of the wearing parts for oil drilling rigs, geological mining tools, agricultural machinery, construction and building materials machinery, etc.

Specifications of Tungsten Carbide Welding Rod| Designations | Specifications | Filling Rate (%) | Typical Applicable areas and working condition | |

| Diameter (mm) | Length (mm) | |||

| XRYD-1 | Φ3.2~Φ6 | 400-1,000 | 60-70 | Having good performance in resisting particles'abrasion in low stress; applicable to the surfacing and repairing of the well drilling and salvage tool, concrete mixing blade, slush pump, coal chute, coal drill pipe, pulverizer blade, dredge blade, high speed sand mixer, etc. |

| XRYD-2 | ||||

| XRYD-3 | Φ3.2~Φ6 | 400-1,000 | 60-70 | Having better performance in resisting particles'abrasion in low stress; particularly applicable to the oil drilling tool and the geological tool, such as steel drill bit and fishtail bit; and the surfacing of the machine parts suffering from the rock and particles' intensive abrasion. |

| XRYD-4 | ||||

| XRYD-5 | Φ3.2~Φ6 | 400-1,000 | 60-70 | Suitable for the working condition of medium impact and abrasion, such as the blades and scrapers of all kinds of mixers, crusher, disk-type scraper, slush pump blade, drill pipe joint, stabilizer, coal cutter pick, cone bit, etc. |

| XRYD-6 | Φ2.8~Φ6 | 400-1,000 | 60-70 | Suitable for the surfacing of the workpiece suffering from higher impact loading, especially the tooth surface and tip of steel tooth bit for oil drilling, drilling rig for mining, coal cutter pick, rip saw tooth, etc. |

Note: We are willing to design and provide the tungsten carbide welding rod according to customers' requirement.

We can also produce tungsten carbide electrodes as per clients specifications. All of our tungsten carbide welding rods can effectively reduce the tool wear and increase the working efficiency.

Links:https://www.globefindpro.com/products/74529.html

-

Metal Matrix Composite (Aluminum Copper Composite Tube)

Metal Matrix Composite (Aluminum Copper Composite Tube)

-

Powder and Fluid Dosing and Mixing Equipment

Powder and Fluid Dosing and Mixing Equipment

-

Dense Phase Pneumatic Conveying System

Dense Phase Pneumatic Conveying System

-

Aluminum Brazing Sheet

Aluminum Brazing Sheet

-

Metal Matrix Composite (Babbitt Metal)

Metal Matrix Composite (Babbitt Metal)

-

Dosing Machine

Dosing Machine

-

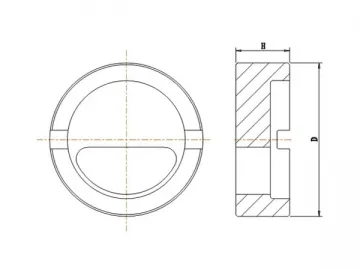

Carbide Tips (for Cutter Picks)

Carbide Tips (for Cutter Picks)

-

MKPH63S Stainless Steel Peripheral Pump for Hot Water

MKPH63S Stainless Steel Peripheral Pump for Hot Water

-

Tungsten Carbide Components (Valve Components)

Tungsten Carbide Components (Valve Components)

-

MF Series Hot Water Centrifugal Pump

MF Series Hot Water Centrifugal Pump

-

Hot Water Circulating Pump

Hot Water Circulating Pump

-

MQP Series Peripheral Pump

MQP Series Peripheral Pump