Counterflow Evaporative Condenser

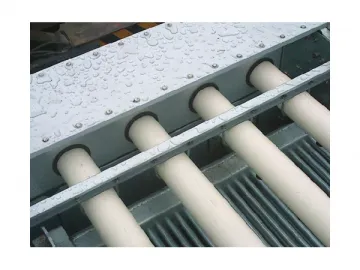

The counterflow evaporative condenser provided by WANXIANG is a specially designed low noise cooling apparatus whose bottom part is inclined to the drain outlet and the heat transfer layer made of PVC fillers is hanged. This elaborate design has made it easier for the sewage and sundries to get out of the condenser. As the evaporative condenser employs the second heat transfer technology and the combination of coils and fillers, it could effectively avoid such problems as the dry points and incrustation on the wall of the coils, efficiently cooling the fluid inside.

The draught fan and circulation pump are all manufactured by quality bearings and there is no other moving wear part. Especially, the draught fan employs a direct-connect structure rather than the belt structure, avoiding the friction and faults caused by the latter. The evaporative condenser is dissected into the upper and lower parts, making it convenient to transport and install the equipment in the field. Now there are two derived types of the condenser available for you now, namely the vertical counterflow evaporative condenser and the horizontal evaporative condenser.

Features of Counterflow Evaporative Condenser

1. This counterflow evaporative cooling device is made of exported galvanized stainless steel plates, the best such product among the world which, credited for its high resistance to corrosion, enjoys a much an expanded lifespan that is 2 to 5 times longer than that of its counterparts.

2. This stainless evaporative condenser employs an axial flow draught fan which is equipped with the aluminum alloy forward-curved blades, an air duct of a streamline aperture, a non-belt transmission structure, and an enclosed self-cooled motor of low noise. The evaporative condenser is featured with smaller size, light weight, sound starting performance, reliable operation and excellent mechanical endurance. Given the above beneficial features, this coutnerflow evaporative condenser has gained trusts from more customers.

Technical Specifications of Counterflow Evaporative Condenser

| TYPE | Heat reflection under nominal operating mode kW | Propeller fan | Water circulation pump | Filling rate kg | Weight | |||||

| Number | Blowing rate | Power kW | Number | Water | Power kW | Net weight kg | Operating kg | |||

| SWL-420N | 420 | 1 | 40000 | 3 | 1 | 45 | 1.5 | 51 | 2272 | 3800 |

| SWL-550N | 55 | 1 | 45000 | 4 | 1 | 45 | 1.5 | 64 | 2555 | 4150 |

| SWL-620N | 620 | 1 | 65000 | 4 | 1 | 65 | 2.2 | 78 | 2830 | 4900 |

| SWL-750N | 750 | 1 | 70000 | 5.5 | 1 | 65 | 2.2 | 88 | 3750 | 5350 |

| SWL-860N | 860 | 2 | 40000(2) | 3(2) | 1 | 65 | 2.2 | 102 | 4220 | 6100 |

| SWL-920N | 920 | 1 | 80000 | 4 | 1 | 65 | 2.2 | 113 | 4470 | 6900 |

| SWL-1050N | 1050 | 2 | 45000(2) | 4(2) | 1 | 100 | 3 | 128 | 5160 | 7200 |

| SWL-1150N | 1150 | 2 | 100000 | 7.5 | 1 | 100 | 3 | 141 | 5390 | 7900 |

| SWL-1250N | 1250 | 2 | 65000(2) | 4(2) | 1 | 100 | 3 | 153 | 5800 | 9200 |

| SWL-1380N | 1380 | 2 | 70000(2) | 5.5(2) | 1 | 100 | 3 | 170 | 6230 | 9700 |

| SWL-1490N | 1490 | 2 | 70000(2) | 5.5(2) | 1 | 130 | 4 | 175 | 6600 | 10600 |

| SWL-1575N | 1575 | 3 | 50000(3) | 3(3) | 1 | 130 | 4 | 192 | 7120 | 10800 |

| SWL-1650N | 1650 | 3 | 50000(3) | 3(3) | 1 | 130 | 4 | 204 | 7990 | 11500 |

| SWL-1765N | 1765 | 2 | 78000(2) | 5.5(2) | 1 | 130 | 4 | 219 | 8220 | 11600 |

| SWL-1950N | 1950 | 3 | 65000(3) | 5.5(3) | 1 | 170 | 5.5 | 230 | 8776 | 12700 |

| SWL-2100N | 2100 | 3 | 75000(3) | 5.5(3) | 1 | 170 | 5.5 | 255 | 9698 | 13200 |

| SWL-2200N | 2200 | 3 | 78000(3) | 5.5(3) | 1 | 170 | 5.5 | 261 | 9858 | 13900 |

| SWL-2300N | 2300 | 2 | 100000(2) | 7.5(2) | 1 | 170 | 5.5 | 281 | 9870 | 14000 |

| SWL-2450N | 2450 | 3 | 78000(3) | 5.5(3) | 1 | 230 | 7.5 | 305 | 10676 | 14600 |

| SWL-2650N | 2650 | 3 | 80000(3) | 4(3) | 1 | 230 | 7.5 | 327 | 11468 | 15800 |

| SWL-2850N | 2850 | 3 | 85000(3) | 7.5(3) | 1 | 230 | 7.5 | 327 | 11626 | 16000 |

| SWL-3120N | 3120 | 3 | 87000(3) | 7.5(3) | 1 | 230 | 7.5 | 392 | 13370 | 17200 |

| SWL-3280N | 3200 | 3 | 100000(3) | 7.5(3) | 1 | 230 | 7.5 | 392 | 13500 | 17350 |

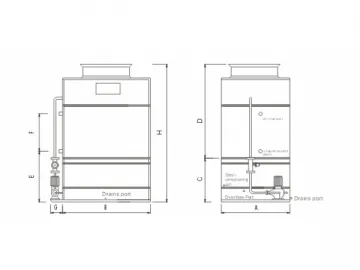

Chart of Operation Principle

Standard Type and Unitary Type

Links:https://www.globefindpro.com/products/74679.html