Valve

CSM valves, especially the super corrosion resistant valve and super abrasion resistance valve not only are with absolute cost advantage, but also can withstand valve working environment and medium corrosion. CSM valve product performs excellently in ocean engineering, space exploration, chemical industry, food processing, medication and health, aerospace industry, equipment and instrument, petroleum industry, etc.

Successful Cases

End User: A Mitsubishi company in Indonesia

Material: TP304, 304L,316L,317L, B381 F3

Type: Ball Valve, Check Valve, Gate Valve, Globe Valve

Selectable material

| Titanium alloy | Titanium (Gr.2, Gr.3, Gr.5, Gr.7, Gr.12) |

| Nickel alloy | Nickel alloy Ni6,Ni200,Ni201 |

| Inconel 600/625/690/750 | |

| Incoloy 800/825/800H/800HT | |

| Monel 400/500 nickel aluminum | |

| Zirconium alloy | Zirconium 702/703/705 |

| Bronze/brass | Nickel-Aluminum-Bronze, Brass, Tin bronze |

| (Super) duplex | A890 4A/5A/6A, F51/53/55 |

| Other corrosion resistant/high temperature resistant metals | 20#, 310S, 321, 904L |

Product Parameter

Size Range

1/4"-60" (50-1,500mm)

Pressure Class

150-4,500lb

Type

Gate Valve, Goble Valve, Plug Valve, Ball Valve, Butterfly Valve, Check Valve, etc.

| Coating method | Type | Hardness RC | Temp. Limitation | Abrasion Resisitance | Corrossion Resisitance |

| Plating | Hard Chormel | 66 | 816℃ | Good | Good |

| Nitriding | 52~72 | 593 ℃ | Good | Good | |

| HVOF | Stellite Chrome Carbide Ni-Cr-Cr3C2 Tungsten Carbide with Cobalt | 44 60~68 55~60 70~72 70~72 | 816 ℃ 816℃816℃482℃482 ℃ | GoodGoodGoodExcellentExcellent | ExcellentExcellentExcellentGoodGood |

| Plasma Spray | Chrome Oxide Titanium Dioxide | 7560 | 538℃ 816℃ | ExcellentGood | GoodExcellent |

Scan QR to Read

Links:https://www.globefindpro.com/products/74878.html

Links:https://www.globefindpro.com/products/74878.html

Recommended Products

-

Titanium Welded Pipe

Titanium Welded Pipe

-

Nickel & Nickel Alloy Forging

Nickel & Nickel Alloy Forging

-

Electric Wire Rope Hoist for Curved Path

Electric Wire Rope Hoist for Curved Path

-

7.5 Ton Electric Chain Hoist

7.5 Ton Electric Chain Hoist

-

Double Motor Electric Wire Rope Hoist

Double Motor Electric Wire Rope Hoist

-

15 Ton Electric Chain Hoist

15 Ton Electric Chain Hoist

-

Nickel & Nickel Alloy Seamless Tube/Pipe

Nickel & Nickel Alloy Seamless Tube/Pipe

-

GYTA Non-Armored Stranded Loose Tube Cable

GYTA Non-Armored Stranded Loose Tube Cable

-

Fujikura CT-30 Series High Precision Optical Fiber Cleaver

Fujikura CT-30 Series High Precision Optical Fiber Cleaver

-

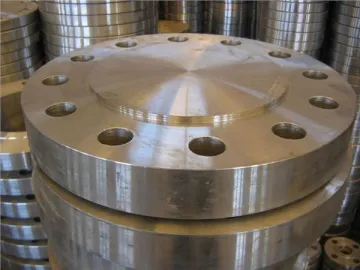

Titanium Flange

Titanium Flange

-

GV-7S High Precision Optical Fiber Cleaver

GV-7S High Precision Optical Fiber Cleaver

-

Nickel & Nickel Alloy Pipe Fitting

Nickel & Nickel Alloy Pipe Fitting

Hot Products