4-16 Industrial Centrifugal Blower

For applications that require a large volume of ambient air at a relatively low pressure, this 4-16 industrial centrifugal blower might be your best bet. This air moving equipment is widely used for ventilating a building, tunnel ventilation, air-drying materials, or as mining ventilation fans, cooling fans, and fans for heat dissipation.

Features of Industrial Centrifugal Blower

1. Annealing process eliminates any internal stresses of the impeller caused by welding, thereby reducing the risk of creepage and cracks.

2. V-belt drive provides an easy way to adjust rotating speeds according to changing loads so that the impeller always runs at peak efficiency.

3. Air ducts and impellers of our industrial centrifugal blower are optimized in design to deliver higher power efficiency.

4. The majority of our air and gas handling products are made of quality carbon steel, but other materials like stainless steel and other metals can be used to satisfy customer requirements.

5. Ultrasonic flaw detection is performed on the weld line to check against any welding defect or material imperfection.

6. Dynamic balancing removes any unbalance that might affect the running stability of our industrial centrifugal blower.

7. Each industrial centrifugal blower has to pass the test run and vibration check before leaving factory.

8. Various other options are available.

Specifications of Centrifugal Fan

| Application | Temperatures | Ambient temperatures | |

| Media | Clean air | ||

| Performance | Impeller diameter | 400-1600 | mm |

| Speed of main shaft | ≤3000 | rpm | |

| Pressure range | 720-6531 | Pa | |

| Flow range | 1966-194495 | m3/h | |

| Structure | Blade | Backward-curved design | |

| Impeller Support | DWDI (Double Width, Double Inlet).For belt-driven impeller or direct drive, one bearing is installed on each side and supported by a support structure that is integrated with fan housing. | ||

| Drive | V-belt drive | Customers can specify the drive type. | |

| Lubrication | Oil bath lubrication | Customers can specify the lubrication type. | |

| Bearing cooling | Air cooling | ||

| System configuration | Motor Brands | SIEMENS, ABB, SIMO, LA | Customers can specify the system configuration. |

| Impeller | Carbon steel | ||

| Impeller cone (Air Inlet) | Carbon steel | ||

| Impeller housing | Carbon steel | ||

| Main shaft | High-strength carbon structural steel | ||

| Bearing | FAG, SKF, ZWZ, C&U | ||

| Bearing housing | Cast iron | ||

| Drive type | V-belt drive | Customers can specify the drive type of the centrifugal fan. | |

| Foundation bolt (or anchor bolt) | Carbon steel | ||

| Options | Unitary base (a support structure), protective mesh screen, Outlet pipeline expansion joint, outlet flange, motor rain cover, temperature sensor, vibration sensor, soft starter, inverter, specialized electrical motor, system monitoring instrument, lube system, overhead lube tank | ||

Links:https://www.globefindpro.com/products/75395.html

-

9-11 Industrial Centrifugal Blower

9-11 Industrial Centrifugal Blower

-

FZ40 Axial Fan for Textile Industry

FZ40 Axial Fan for Textile Industry

-

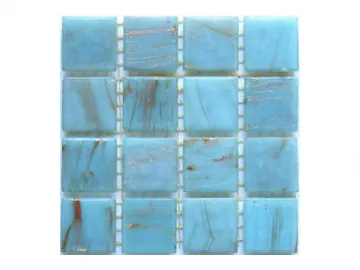

Swimming Pool Mosaic Tile

Swimming Pool Mosaic Tile

-

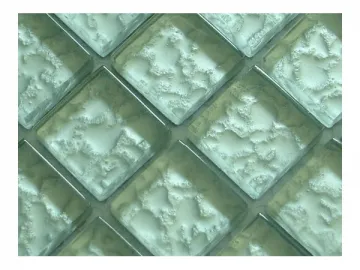

Cold Spray Crystal Glass Mosaic Tile

Cold Spray Crystal Glass Mosaic Tile

-

MQ Explosion Proof Centrifugal Fan

MQ Explosion Proof Centrifugal Fan

-

7-09 Heavy Duty Centrifugal Fan

7-09 Heavy Duty Centrifugal Fan

-

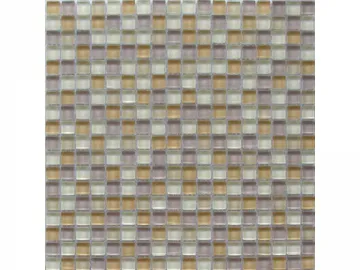

Color Blend Crystal Glass Mosaic Tile

Color Blend Crystal Glass Mosaic Tile

-

9-03 Industrial Centrifugal Blower

9-03 Industrial Centrifugal Blower

-

L-Ornithine L-Aspartate

L-Ornithine L-Aspartate

-

SAM-Polyquat 11 (Polyquaternium-11)

SAM-Polyquat 11 (Polyquaternium-11)

-

Piroctone Olamine

Piroctone Olamine

-

Alkyl Polyglucoside

Alkyl Polyglucoside