9-11 Industrial Centrifugal Blower

Some companies purchase oversized industrial centrifugal blowers for their ventilation, air supply or discharge requirements. They often generate excess energy flow and higher than normal airflow noise. Consequently, oversized fans cost more to purchase and operate. Now we roll out this 9-11 medium-pressure industrial centrifugal blower to handle your air movement applications while allowing high-volume airflow. Listed below are a few of many uses for our low-noise centrifugal fan.

1. Moving clean air at ambient temperatures

2. Feeding air to boilers, furnaces, or rotary kilns

3. Forced ventilation, forced cooling, heat dissipation

4. Air-drying materials, cooling down hot cement clinker

5. Papermaking

Features of Industrial Centrifugal Blower

1. The 9-11 medium pressure industrial centrifugal blower is capable of delivering high-pressure airflow while creating little noise.

2. With the aid of an integral base, even a layman is able to install this high-capacity fan on any desired spot.

3. Flexible coupling is used to connect between the motor drive shaft and the fan shaft. This connection method eliminates the need for belts and pulleys, requiring limited maintenance work.

4. Impellers with diameters below 1400mm run at ambient temperatures. Running at low temperature eliminates the need for bearing cooling devices, which reduces cost and maintenance.

5. When the resistance to airflow increases, the motor load will automatically decrease to protect the motor against burning out.

6. Most of our industrial centrifugal blowers are made of high quality carbon steel, but customers can choose other materials like stainless steel or other metals to construct the fan.

7. Each industrial centrifugal blower has to pass the test run and vibration check before leaving factory.

Specifications

| Application | Temperature | Ambient temperatures | |

| Media | Clean Air | ||

| Performance | Impeller diameter | 400-3000 | mm |

| Speed of main shaft | ≤4000 | rpm | |

| Pressure range | 364.8-8683 | Pa | |

| Flow range | 603.7-154074 | m3/h | |

| Structure | Blade | Backward-inclined design | |

| Impeller Support | SWSI (Single Width, Single Inlet), overhung impeller | ||

| Drive type | Direct drive (with flexible coupling) | Customers can determine the drive type. | |

| Lubrication | Oil bath lubrication | The lubrication method can be specified by customers. | |

| Bearing cooling | Air cooling or Circulating Water cooling | ||

| System configuration | Motor brands | SIEMENS, ABB, SIMO, LA | Or determined by customers. |

| Impeller | Carbon steel | ||

| Impeller cone (Air Inlet) | Carbon steel | ||

| Impeller Housing | Carbon steel | ||

| Air damper | Carbon steel | ||

| Main shaft | High-strength carbon structural steel | ||

| Bearing | FAG, SKF, ZWZ, C&U | ||

| Bearing housing | Cast iron | ||

| Drive type | Direct drive (with flexible coupling) | Or determined by customers. | |

| Foundation bolt (anchor bolt) | Carbon steel | ||

| Options | Support structure (unitary base), protective mesh screen silencer, inlet & outlet pipeline expansion joint, inlet & outlet flange, damper, electric actuator, vibration isolator, diaphragm coupling, fluid coupling, motor rain cover, temperature sensor, vibration sensor, soft starter, inverter, specialized electrical motor, system monitoring instrument, lube system, overhead lube tank. | ||

Links:https://www.globefindpro.com/products/75396.html

-

FZ40 Axial Fan for Textile Industry

FZ40 Axial Fan for Textile Industry

-

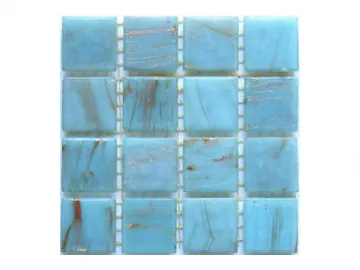

Swimming Pool Mosaic Tile

Swimming Pool Mosaic Tile

-

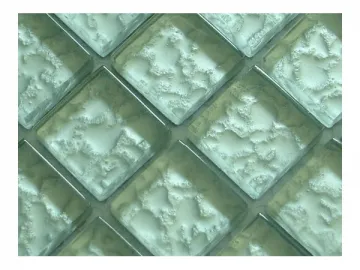

Cold Spray Crystal Glass Mosaic Tile

Cold Spray Crystal Glass Mosaic Tile

-

MQ Explosion Proof Centrifugal Fan

MQ Explosion Proof Centrifugal Fan

-

7-09 Heavy Duty Centrifugal Fan

7-09 Heavy Duty Centrifugal Fan

-

4-10 Industrial Centrifugal Blower

4-10 Industrial Centrifugal Blower

-

4-16 Industrial Centrifugal Blower

4-16 Industrial Centrifugal Blower

-

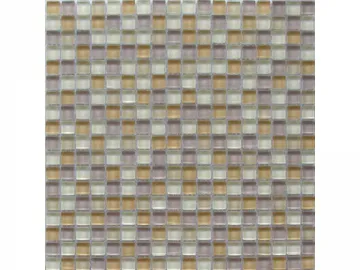

Color Blend Crystal Glass Mosaic Tile

Color Blend Crystal Glass Mosaic Tile

-

9-03 Industrial Centrifugal Blower

9-03 Industrial Centrifugal Blower

-

L-Ornithine L-Aspartate

L-Ornithine L-Aspartate

-

SAM-Polyquat 11 (Polyquaternium-11)

SAM-Polyquat 11 (Polyquaternium-11)

-

Piroctone Olamine

Piroctone Olamine