5-12 Industrial Centrifugal Blower

The 5-12 industrial centrifugal blower brings meaningful improvements over previous 5-11 generations. It meets customer requirements for higher volume air output. Similar to 5-11 centrifugal fans in functions, the latest 5-12 air and gas handling equipment is commonly used to convey gases and hard materials. Specific applications include the following.

1. Draft inducers for industrial boilers, cement production lines, or circulating fluidized bed systems

2. Flue gas discharge, flue gas desulphurization, or flue gas denitration

3. Blower fans for coke ovens

4. Blower fans for drying systems, industrial dust collector fans, blowers for industrial waste heat recovery

5. Blower fans for sinter machines

6. Smoke and heat exhaust fans

Features of Industrial Centrifugal Blower

1. Designed specially for material handling fan applications that involve high temperature, wear and corrosion, the 5-12 industrial centrifugal blower delivers relatively high pressure, large-volume air output while generating low noise.

2. Annealing process removes any internal stresses of the impeller caused by welding, making it unlikely to deform or crack.

3. Different combinations of belt and pulley provides variable rotating speeds, allowing the industrial centrifugal blower always to operate at peak efficiency point thereby saving energy.

4. Linear guides are added to facility belt tightening, minimizing the energy loss caused by a slack belt.

5. There is space left inside the bearing housing to allow for the installation of temperature sensor and vibration sensor which would facilitate the monitoring of fan operating status.

6. Liquid lubricating grease is used to reduce friction. Replacement or refilling of lubricating grease can be done without the need to open the journal box. Via the sight glass, centrifugal blower users can observe the oil level and oil quality.

7. Dynamic balancing eliminates any unbalance that might affect the running stability.

8. Each medium-pressure industrial centrifugal blower needs to pass the test run and vibration check before leaving factory.

Specifications

| Application | Temperatures | Ambient temperatures | |

| Hot Air | |||

| Media | Clean air | ||

| Dusty air | |||

| Corrosive gas | |||

| Combustible gas | |||

| Powdery materials | |||

| Lightweight particles | |||

| Performance | Impeller diameter | 400-3300 | mm |

| Speed of main shaft | ≤4000 | rpm | |

| Pressure range | 684-8687 | Pa | |

| Flow range | 590.4-700735 | m3/h | |

| Structure | Blade | Backward-inclined design | |

| Impeller Support | SWSI (Single Width, Single Inlet), overhung impeller. | ||

| Drive type | V-belt drive | Customers can determine what kind of drive should be used. | |

| Lubrication | Oil bath lubrication | Determined by customers | |

| Bearing cooling | Air cooling or Circulating Water cooling | ||

| System configuration | Motor | SIEMENS, ABB, SIMO, LA | Specified by customers |

| Impeller | Carbon steel | ||

| Impeller cone (Air Inlet) | Carbon steel | ||

| Impeller housing | Carbon steel | ||

| Air damper | Carbon steel | ||

| Main shaft | High-strength carbon structural steel | ||

| Bearing | FAG, SKF, ZWZ, C&U | ||

| Bearing housing | Cast iron | ||

| Drive | Direct drive (with flexible coupling) | Specified by customers. | |

| Foundation bolt | Carbon steel | ||

| Options | Unitary base (a support structure), protective mesh screen, outlet pipeline expansion joint, outlet flange, motor rain cover, temperature sensor, vibration sensor, soft starter, inverter, specialized electrical motor, system monitoring instrument, lube system, overhead lube tank | ||

Links:https://www.globefindpro.com/products/75407.html

-

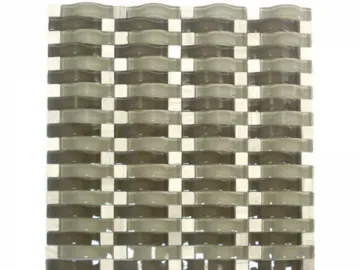

Custom Design Mosaic Tile Pattern

Custom Design Mosaic Tile Pattern

-

Glass and Stone Mosaic Tile

Glass and Stone Mosaic Tile

-

Glacier Glass Mosaic

Glacier Glass Mosaic

-

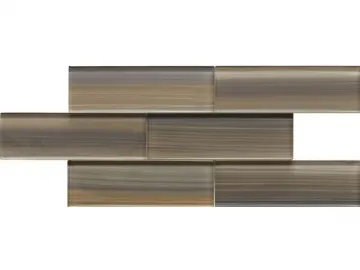

Glass Subway Tile

Glass Subway Tile

-

Gold and Silver Glass Mosaic Tile

Gold and Silver Glass Mosaic Tile

-

Hand Painted Glass Mosaic Tile

Hand Painted Glass Mosaic Tile

-

Ripple Glass Mosaic

Ripple Glass Mosaic

-

6-05 Industrial Centrifugal Blower

6-05 Industrial Centrifugal Blower

-

Filter Fan for Cement Mill

Filter Fan for Cement Mill

-

4-09 Industrial Centrifugal Blower

4-09 Industrial Centrifugal Blower

-

4-10 Industrial Centrifugal Blower

4-10 Industrial Centrifugal Blower

-

7-09 Heavy Duty Centrifugal Fan

7-09 Heavy Duty Centrifugal Fan