4-10 Heavy Duty Centrifugal Fan

The 4-10 heavy duty centrifugal fan is indeed an improvement over previous 4-10 series in many ways. Though similarly functional and useful to its predecessor, model 4-10 high pressure fan allows a larger volume of air-stream to pass at higher pressure. One primary use of the enhanced heavy duty centrifugal fan is in large-scale industrial systems, where it is employed as smoke exhaust fan, draft inducer for boilers, dust collection fan, or for flue gas desulfurization, flue gas denitration, cement production, and power generation.

Features of Heavy Duty Centrifugal Fan

1. Whether your application requires high temperature or high pressure, SIMO BLOWER has the right high-capacity fan for your needs which provides high volumes of air while generating low noise.

2. Ultrasonic flaw detection is performed on the welded impeller and the main shaft to check against any weld imperfections and material defects.

3. Dynamically balanced impeller of the centrifugal blower ensures running stability.

4. Detachable parts make fan maintenance easier than before.

5. Impeller blades are set an optimal angle to the direction of rotation. This arrangement allows the blades to be more durable and wear resistant.

6. Designed specially to handle dusty air, the 4-10 multifunctional fan blower has its blades surface treated to achieve high hardness of HRC60~70. Hardened impeller provides 3 times the lifespan of an ordinary impeller.

7. Each heavy duty centrifugal fan is pre-assembled to ensure parts fit in well with each other.

8. Every fan part is imprinted with an installation number. Users can easily install the heavy duty centrifugal fan if the installation instructions are properly followed.

9. We can provide on-site services.

10. Multiple options are available.

Specifications

| Application | Temperature | Ambient temperatures | |

| Hot Air | |||

| Media | Clean air | ||

| Dusty air | |||

| Powder materials | |||

| Lightweight particles | |||

| Performance | Impeller diameter | 1500~3150 | mm |

| Speed of main shaft | ≤1450 | rpm | |

| Pressure range | 2081-9260 | Pa | |

| Flow range | 67120-1050384 | m3/h | |

| Structure | Blade | Backward inclined design | |

| Impeller Support | SWSI (Single Width, Single Inlet), There is one bearing on each side of the fan, which is supported by separate pedestals. | ||

| Drive type | Direct drive (with flexible coupling) | Or determined by customers. | |

| Lubrication | Oil bath lubrication | Or determined by customers. | |

| Bearing cooling | Circulating water cooling | ||

| Circulation oil cooling | |||

| System configuration | Motor | SIEMENS, ABB, SIMO, LA | Or determined by customers. |

| Impeller | Carbon steel | ||

| Impeller cone (Air Inlet) | Carbon steel | ||

| Impeller housing | Carbon steel | ||

| Air damper | Carbon steel | ||

| Main shaft | High-strength carbon structural steel | ||

| Bearing | FAG, SKF, ZWZ, C&U | ||

| Bearing housing | Cast iron | ||

| Drive type | Coupling | Or determined by customers. | |

| Foundation bolt | Carbon steel | ||

| Options | Unitary base (a pedestal or support structure), protective mesh screen, silencer, inlet and outlet pipeline expansion joint, inlet and outlet flange, damper, electric actuator, vibration isolator, diaphragm coupling, fluid coupling, motor rain cover, temperature sensor, vibration sensor, soft starter, inverter, specialized electrical motor, system monitoring instrument, lube system, overhead lube tank | ||

Links:https://www.globefindpro.com/products/75422.html

-

6-11 Single Inlet Centrifugal Fan

6-11 Single Inlet Centrifugal Fan

-

6-12 Heavy Duty Centrifugal Fan

6-12 Heavy Duty Centrifugal Fan

-

Kingpin

Kingpin

-

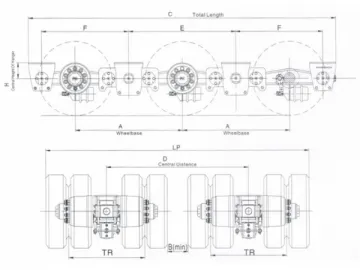

Three-Axle Cantilever Suspension

Three-Axle Cantilever Suspension

-

Lowbed Trailer Axle

Lowbed Trailer Axle

-

6-2X11 Double Inlet Centrifugal Fan

6-2X11 Double Inlet Centrifugal Fan

-

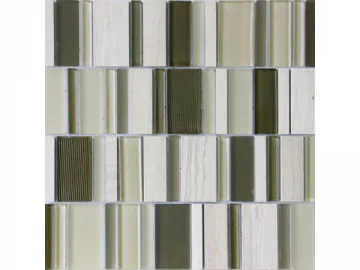

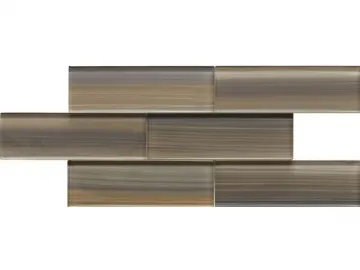

Yunsen Series Glass Mosaic

Yunsen Series Glass Mosaic

-

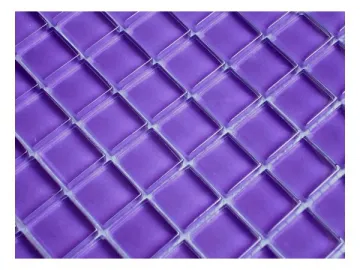

Pure Color Crystal Glass Mosaic Tile

Pure Color Crystal Glass Mosaic Tile

-

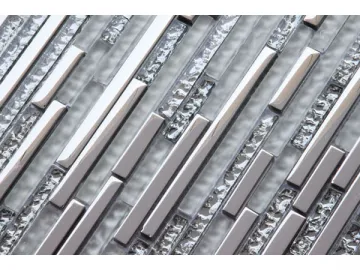

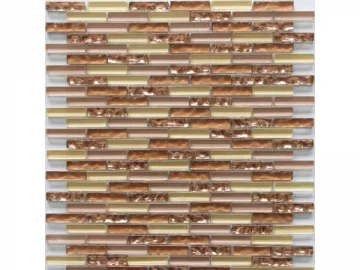

Glass Stick Mosaic Tile

Glass Stick Mosaic Tile

-

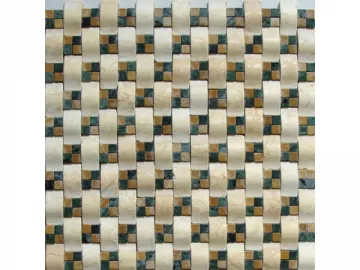

Mini Brick Glass Mosaic

Mini Brick Glass Mosaic

-

Marble / Nature Stone Mosaic Tile

Marble / Nature Stone Mosaic Tile

-

Hand Painted Glass Mosaic Tile

Hand Painted Glass Mosaic Tile