6-11 Single Inlet Centrifugal Fan

Designed to create high pressure airflow, the 6-11 single inlet centrifugal fan is specially prepared to handle heavy duty air-moving tasks. Most commonly used to transport incombustible gases, particles, powders, scraps and fibers at ambient temperature or high temperature, the single inlet centrifugal fan is frequently used as:

1. Large-scale dust collection fan

2. Fan for flue gas desulfurization or denitration systems

3. Blower fan for industrial boilers, industrial-grade rotary kilns, sinter machines, and minerals calcination systems.

Features of Single Inlet Centrifugal Fan

1. The 6-11 single inlet centrifugal fan is suitable for high-pressure, high-temperature air moving applications.

2. Whatever the media temperature or rotary speed you want, SIMO BLOWER has the right materials to construct the impeller and shaft that are up to the task. Customers can choose among high-strength carbon steel, low alloy steel, high-temperature resistant alloy, and high temperature resistant high-strength alloy steel to build quality industrial fans that stand up to temperature extremes.

3. Built to deal with dust-laden air, the single inlet centrifugal fan has its impeller blades specially treated to achieve high hardness of HRC60~70. Performance tests show that our impeller lasts 3 times as long as an ordinary impeller.

4. Whether you are considering a standard centrifugal fan or a custom design, SIMO BLOWER has the right solution for you. Each customized heavy duty fan is optimized by CFD technology achieve more energy savings.

5. Annealing process removes any internal stresses of the impeller caused during welding. No creepage or cracks will ever occur!

6. Ultrasonic flaw detection is performed on the weld line and impeller shaft to check against weld imperfections and material defects.

7. Dynamic balancing eliminates any unbalance that might affect the running stability of the centrifugal blower.

8. Each new single inlet centrifugal fan is preassembled to ensure parts do not interfere with each other.

Specifications

| Application | Temperature | Ambient temperatures | |

| Hot Air | |||

| Media | Clean air | ||

| Dusty air | |||

| Powdery materials | |||

| Lightweight particles | |||

| Performance | Impeller diameter | 1500-3600 | mm |

| Speed of main shaft | ≤1450 | rpm | |

| Pressure range | 2304-14068 | Pa | |

| Flow range | 52395-575176 | m3/h | |

| Structure | Blade | Backward-inclined design | |

| Impeller Support | SWSI (single width, single inlet), self-supported bearing housing, one bearing on either side of the fan which is supported by separate pedestals. | ||

| Drive type | Direct drive (with flexible coupling) | Or determined by customers. | |

| Lubrication | Oil bath lubrication | Or determined by customers. | |

| Bearing cooling | Circulating Water cooling | ||

| Circulation Oil cooling | |||

| System configuration | Motor | SIEMENS, ABB, SIMO, LA | Or determined by customers. |

| Impeller | Carbon steel | ||

| Impeller cone (Air Inlet) | Carbon steel | ||

| Impeller housing | Carbon steel | ||

| Air damper | Carbon steel | ||

| Main shaft | High-strength carbon structural steel | ||

| Bearing | FAG, SKF, ZWZ, C&U | ||

| Bearing housing | Cast iron | ||

| Drive type | Direct drive (with flexible coupling) | Or determined by customers. | |

| Foundation bolt | Carbon steel | ||

| Options | Unitary base (a pedestal or support structure), protective mesh screen, silencer, inlet and outlet pipeline expansion joint, inlet and outlet flange, damper, electric actuator, vibration isolator, diaphragm coupling, fluid coupling, motor rain cover, temperature sensor, vibration sensor, soft starter, inverter, specialized electrical motor, system monitoring instrument, lube system, overhead lube tank | ||

Links:https://www.globefindpro.com/products/75423.html

-

6-12 Heavy Duty Centrifugal Fan

6-12 Heavy Duty Centrifugal Fan

-

Kingpin

Kingpin

-

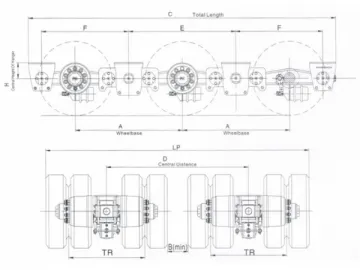

Three-Axle Cantilever Suspension

Three-Axle Cantilever Suspension

-

Lowbed Trailer Axle

Lowbed Trailer Axle

-

6-2X11 Double Inlet Centrifugal Fan

6-2X11 Double Inlet Centrifugal Fan

-

Rotary Table

Rotary Table

-

4-10 Heavy Duty Centrifugal Fan

4-10 Heavy Duty Centrifugal Fan

-

Yunsen Series Glass Mosaic

Yunsen Series Glass Mosaic

-

Pure Color Crystal Glass Mosaic Tile

Pure Color Crystal Glass Mosaic Tile

-

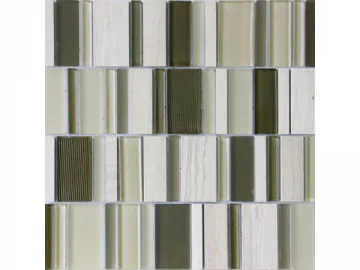

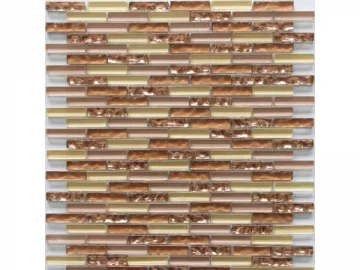

Glass Stick Mosaic Tile

Glass Stick Mosaic Tile

-

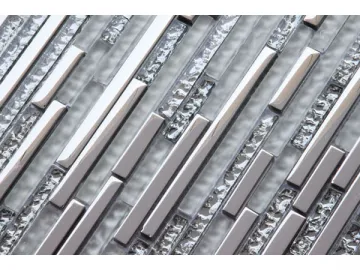

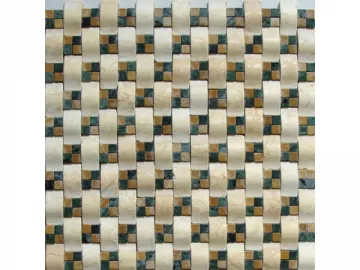

Mini Brick Glass Mosaic

Mini Brick Glass Mosaic

-

Marble / Nature Stone Mosaic Tile

Marble / Nature Stone Mosaic Tile