7-07 Industrial Centrifugal Blower

Whether your application involves high operating temperatures, corrosive or high pressure environments, SIMO BLOWER has the right industrial centrifugal blower for your severe environments. Typical uses for our 7-07 industrial centrifugal blower are listed in the following.

1. Air and gas handling applications or material handling fan systems, such as transporting high temperature gas, toxic fume, pulverized coal, or hard particles, powders, scraps or fibers

2. Forced draft fans or induced draft fans for industrial boilers, casting furnaces, or smelting furnaces

3. Industrial dust collection fans and blowers, air filtration system, forced ventilation, flue gas desulphurization, flue gas denitration

4. Supplying lightweight materials to rotary kilns, calcination kilns

5. Boosting combustion efficiency or pulverized coal ejection in blast furnaces

6. Increasing the coal gas pressure to facilitate transportation

Features of Industrial Centrifugal Blower

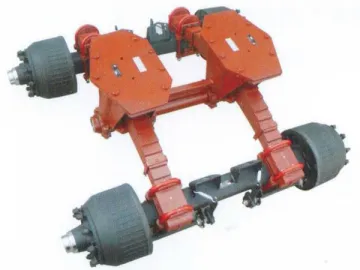

1. Designed to handle high pressure gases, the 7-07 industrial centrifugal blower also has high temperature resistance, which makes it suitable for use in high temperature and high pressure industrial settings.

2. Installation is easily done with the aid of the unitary base.

3. Standard fan models are made of high quality carbon steel. Customers can determine what materials to use in the construction of your high-pressure centrifugal fan such as stainless steel or other metals.

4. This industrial centrifugal blower is especially suitable for dealing with dusty air. Its blades have been specially treated to achieve high hardness of HRC60~70. Improved hardness extends the impeller's lifespan by 3 times.

5. Tight-fitting parts provide a good seal which avoids airflow pressure loss.

6. Ultrasonic flaw detection is performed on the weld line and the main shaft to check against any weld imperfections and material defects.

7. Dynamic balancing removes any unbalance of the impeller that might affect its running stability.

8. Each high-pressure industrial centrifugal blower needs to pass the test run and vibration check before leaving factory.

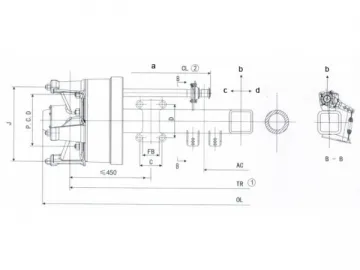

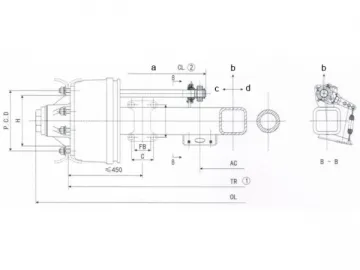

Specifications

| Application | Temperature | Ambient temperatures | |

| Hot Air | |||

| Media | Clean air | ||

| Dusty air | |||

| Corrosive gas | |||

| Combustible gas | |||

| Powdery materials | |||

| Lightweight particles | |||

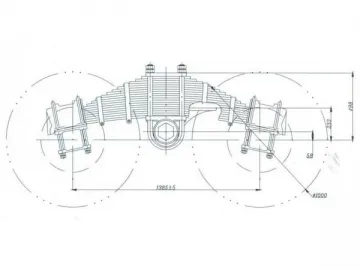

| Performance | Impeller diameter | 500-3000 | mm |

| Speed of main shaft | ≤4000 | rpm | |

| Pressure range | 451-27519 | Pa | |

| Flow range | 173-100788 | m3/h | |

| Structure | Blade | Backward inclined design | |

| Impeller Support | SWSI (Single Width, Single Inlet), overhung impeller. | ||

| Drive type | V-belt drive | Or determined by customers. | |

| Lubrication | Oil bath lubrication | Or determined by customers. | |

| Bearing cooling | Air cooling or Circulating Water cooling | ||

| System configuration | Motor | SIEMENS, ABB, SIMO, LA | Or determined by customers. |

| Impeller | Carbon steel | ||

| Impeller cone (Air Inlet) | Carbon steel | ||

| Impeller housing | Carbon steel | ||

| Air damper | Carbon steel | ||

| Main shaft | High-strength carbon structural steel | ||

| Bearing | FAG, SKF, ZWZ, C&U | ||

| Bearing housing | Cast iron | ||

| Drive | V-belt drive | Or determined by customers. | |

| Foundation bolt | Carbon steel | ||

| Optional components | Unitary base (a support structure), protective mesh screen, outlet pipeline expansion joint, outlet flange, motor rain cover, temperature sensor, vibration sensor, soft starter, inverter, specialized electrical motor, system monitoring instrument, lube system, overhead lube tank | ||

Links:https://www.globefindpro.com/products/75445.html