M200 High Performance Vector Control Variable Frequency Drive

Although many motors require a vector drive specific to their makes and models, many drives are now available that are compatible with a wide variety of motors. The M200 series general-purpose vector control variable frequency drive uses a specialized digital signal processor to handle a variety of digital and analog signals. The fast data processing speed of DSP means the motor is quicker than before to respond to varying loads and correct for operating errors.

Advanced vector control algorithm uses feedback information to precisely calculate the vector of motor current, and adjusts for any current errors. This mathematical operation also allows for decoupling control. Typical benefits of using our vector control variable frequency drive include high starting torque at low frequency, precise torque and speed control, and high responsiveness.

Technical Specifications

| Power range | 3 Phase 380V 0.75-93KW, 1 Phase 220V 0.75KW-2.2KW |

| Output frequency | 0~600Hz |

| Frequency accuracy | Digital mode: max frequency× /- 0.01% |

| Analog mode : max frequency× /- 0.2% | |

| Frequency resolution | Digital mode :0.01Hz |

| Analog mode: max frequency×0.1% | |

| Control mode | V/F controlSVC vector control |

| Torque rise | Automatic torque riseManual torque boost: 1%~30.0% (only applicable to V/F control mode) |

| Torque | 180% rated torque at 0.5HZ |

| Built-in PID controller | The PID controller collects feedback information from the motor sensor, compare the actual motor status to desired motor status, and adjust for any status errors. It completes the closed-loop control system in a motor which is applicable for precise flow rate and pressure control. |

| Multiple preset speeds | A total of 16 operating speeds are provided. |

| Operator interface | 2 analog signal inputs, 1 analog signal output, 8 discrete input (DI6 high-speed pulse input port), 2 programmable open collector outputs, 1 programmable relay output |

| Serial communication port | Standard RS-485 serial communication interface |

| Protections | Over-voltage, under-voltage, input phase-loss, overload, overheat, over current, external terminal fault, serial bus communication fault, current detection error, motor tuning fault, etc., totaling 20 protections |

Features of Vector Control

I. Torque

1. Each vector control variable frequency drive comes with a digital signal processor that is specially designed for T1 high-speed motor controller. The DSP technology enables fast, accurate calculation of the current vector, allowing for complete motor decoupling.

2. Advanced vector control algorithm is used to deliver 180% of rated torque at 0.5Hz with speed adjustment accuracy of 0.5%. Please note that this senseless vector control works optimally at the speed of 1:100.

II. Simplified PLC system maintains motor control over 16 speed ranges.

III. Built-in PID controller, together with the programmable logic controller, forms a complete closed loop motor control system. It is quite effective in controlling flow rate and pressure.

IV. Standard RS-485 interface supports Modbus, and sets up communicative connections with the touch screen, PLC, etc.

V. All M200 models adopt modular design for maximum interchangeability. Models below 15kw come in compact designs, featuring all-plastic construction. They are more cost effective than larger-power versions.

VI. DC powered fans are available in medium and large-power models of our high-performance vector control variable frequency drive for outstanding cooling performance. DC contractors are used in place of AC contractors due to their better dust-proof performance.

VII. Each vector control variable frequency drive offers protections against over voltage, under voltage, input phase loss, overload, overheat, over current, external terminal fault, serial bus communications fault, current detection error, motor turning fault, etc., totaling 20 protections.

VIII. New Models Tailored to Diverse Applications

Present applications for our high-performance vector control variable frequency drive are in the rotary cutting, NC machining, pipe piling, and air compressing tasks, among various other uses.

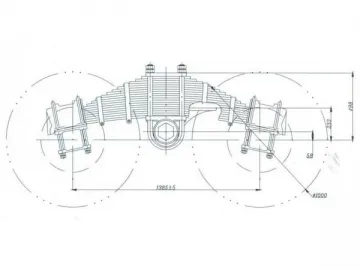

Vector Control Installation Size

| M200 Series specification list | |||||||

| series | KW | H(mm) | W(mm) | D(mm) | H1(mm) | W1(mm) | R(mm) |

| power | Shell Size | Installation Size | Aperture | ||||

| M200 | 0.7-2.5 section aluminum | 185 | 118 | 152 | 173 | 108 | 5.5 |

| 4kw section aluminum | 185 | 118 | 173 | 173 | 108 | 5.5 | |

| 5.5-7.5 section aluminum | 260 | 150 | 166 | 244 | 135 | 7 | |

| 0.7-4 All plastic shell | 185 | 118 | 170 | 173 | 108 | 5.5 | |

| 5.5-7.5 All plastic shell | 260 | 150 | 170 | 248 | 138 | 5.5 | |

| 11-15 All plastic shell | 322 | 217 | 210 | 301 | 200 | ①:6 ②6.5*9 | |

| 18.5-22 | 452 | 262 | 240 | 432 | 180 | 8 | |

| 30-37 | 519 | 305 | 268 | 488 | 180 | 10 | |

| 45-55 | 593 | 340 | 302 | 568 | 220 | 10 | |

| 75-93 | 658 | 390 | 312 | 628 | 240 | 12 | |

2. Input and Output

| Input | Rated voltage and frequency | Single 220V, three-phase 220V, three-phase 380V, 50Hz/60Hz |

| Allowable variations (tolerance) | Voltage: -20%~ 20%Voltage unbalance: <3%Frequency: ±5% Hz | |

| Output | Rated voltage | 0~220V/0~380V |

| Frequency range | 0Hz~600Hz |

| Main control function | Modulation mode | Voltage Vector PWM Modulator |

| Control mode | Sensorless vector control | |

| Frequency accuracy | Digital mode: max frequency ×± 0.01%Analog mode: max frequency ×±0.2% | |

| Frequency resolution | Digital mode: 0.01HzAnalog mode: max frequency×0.1% | |

| Start frequency | 0.0Hz~10.00Hz | |

| Torque rise | Auto torque riseManual torque rise: 1%~30.0% (Only applicable for V/F control mode) | |

| Torque | 150% of rated torque at 0.5Hz | |

| V/F curve | Linear V/F curveQuadratic V/F curveUser-defined V/F curve | |

| S-curve acceleration/deceleration | Maximum time: 6000s (adjustable with the range of 0.1~3600s). | |

| DC braking unit | Operating time: 0~50s | |

| Jog switch | Jog frequency range: 0.1Hz~50.00HzJog acceleration and deceleration time: 0.1~3600s. | |

| Built-in PID controller | A closed-loop control system is formed with the aid of PID controller, which is suitable for controlling flow rate and pressure in an industrial automation system . | |

| Multiple operational speeds | 16 operating speeds are available | |

| Auto voltage adjustment | The high-performance vector control variable frequency drive is able to maintain a constant voltage level by adjusting its PWM outputs. | |

| Auto current control | Current-limiting features prevent the sensorless vector drive tripping on a fault caused by excess current. | |

| Automatic display of motor operating parameters | Check parameters on the display when the motor completely stops in order to achieve optimal control. |

| Run Enable | Command channels | Selection of operating modesSetting of control terminalSetting of serial port |

| Frequency adjustment | ▲, ▼ command buttonsFunctional codeSerial portUP/DOWN terminalsAnalog voltageAnalog current ; Pulse output | |

| Discrete input | 7 programmable discrete inputs that support max. 30 functions | |

| Analog input | Dual-channel analog signal input, 0~20mA, 0~ 10V | |

| Analog output | Dual-channel analog signal output 0~10V, 0~20mA separately control the output of physical quantities like frequency and torque | |

| Discrete output | 2-way programmable open collector output, 1-way relay output |

Use of Vector Control in Industry

M200 high-performance vector control variable frequency drive can be applied to CNC, petrochemical industry, electric power, papermaking, plastics, ceramic, stone, construction materials, textile, dyeing, woodworking industries, etc.

Links:https://www.globefindpro.com/products/75457.html