Balloon Printing Ink

Specifications of Balloon Printing Ink

| Trio Chem Screen Printing Solutions (for inks of regular production) | |

| Field of Use (substrate details) | Characteristics and Properties |

| TRIOCHEM EVA Screen Print Ink (RP series) | |

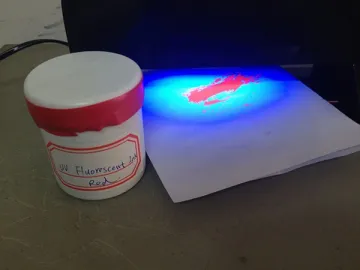

| EVA material | Excellent adhesion, excellent color migration resistance in overprinting; Good hiding power, suitable for air and forced drying. |

| TPR, Common Rubber | |

| Foam Slipper, Balloon | |

| Latex Swim Caps | |

| TRIOCHEM Nylon Screen Printing Ink (SND, SNC, SNK series) | |

| PET and PA fiber | High flexibility and softness, excellent elasticity; High elongation, good hiding power, suitable for air and forced drying. |

| Nylon and Tetoron Fabric | |

| Genuine and Artificial Leather | |

| PU Leather, Nubuck | |

| TRIOCHEM Rubber Screen Printing Ink (Vulcanization in label transfer printing via PET carrier) | |

| Tyre Sidewall | High glossy, high color density and elasticity; Excellent adhesion after transferring printing, suitable for one-off or repeated vulcanization. |

| V-belt | |

| Rubber Ball | |

| NR, SBR, SSBR, BR, EPDM, NBR | |

| TRIOCHEM PVC Screen Printing Ink (SB and SS series) | |

| Flexible and Rigid PVC | Superior adhesion, good flexibility and elasticity, tack-free surface drying, good abrasion, scratch and scuff resistance; Suitable for air and forced drying. |

| Paper Material | |

| Wood Material | |

| PVC Artificial Leather | |

Scan QR to Read

Links:https://www.globefindpro.com/products/75529.html

Links:https://www.globefindpro.com/products/75529.html

Recommended Products

Hot Products