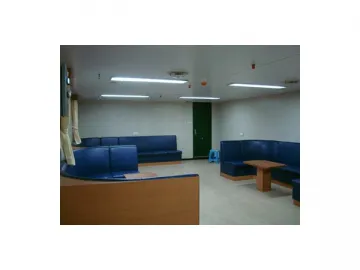

B15 Fireproof Door

Producing a marine fireproof door involves the following procedures, namely, door frame manufacturing, door panel processing, core panel fabricating, main parts assembling, side panel fixing, hinge connection between door leaf and frame, lock installation, and wrapping.

Features

1. The frame of our fireproof door is made of 1.5mm-thick galvanized steel plate with baking varnish. Compared with door frame made of common baking varnish coated steel plate, the frame of our fire door is not easy to deform and has long service life. Since this door is specially used in the ship cabinet, we configure a ventilation grid at the bottom of the door facilitating seamen escaping under emergent situations.

2. The accessories such as lock, handle and hinge assembled on our fireproof doors are produced by large domestic hardware manufacturers.

3. This fire resistant door makes low noise when it is opened or closed. In addition, it is easy to install and maintain.

Parameters

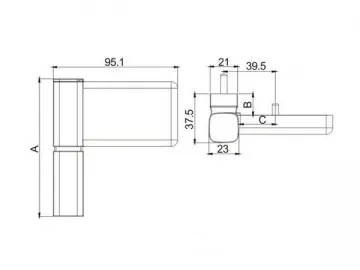

| Order | Product name | Door frame type | Trunk bulkhead hole size | Depth |

| 1 | B15 fireproof door (with window and ventilation grid for escaping) | Box-type | (HC 100)× (WC 100) | T 50 |

| 2 | B15 fireproof door (with window and ventilation grid for escaping) | Z-type | (HC 65)× (WC 80) | 65 |

| Door leaf | Surface material: 1mm-thick steel plateCore material: 10mm-thick calcium silicate board; 28mm-thick ceramic wool panel;Total thickness: 40mmOptional configurations: escape exit in the size of 540mm×440mm, lock and hinge | |||

| Door frame | Box-type: 1.5mm-thick steel plate with baking varnish | |||

| Z-type: 1.5mm-thick galvanized steel plate with baking varnish | ||||

Links:https://www.globefindpro.com/products/75680.html