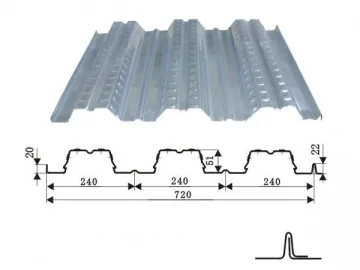

Steel Decking Sheet

The steel decking sheet refers to the corrugated steel sheet. It serves not only as a permanent formwork for concrete floor, but also as a load-bearing bar at the bottom of the floor that also participates in the stress calculation. Together with the concrete, the steel floor decking sheet can be regarded as a composite floor deck.

Advantages

A composite floor using the steel decking sheet has the following advantages:

1. Save a lot of temporary formworks. Save all or part of formwork supports. Reduce concrete consumption.

2. Reduce the permanent load of the structure, which is significant to high-rise buildings and buildings in earthquake zones. What is more important, it saves a lot of labor in delivery, stacking, and installation.

3. Reduce the workload in the laying of communication, electricity, heating and other pipelines.

4. Facilitate the settlement of heat insulation, sound insulation, shock isolation and other materials.

5. Improve floor performance. Give full play to the excellent tensile strength and ductility of the steel, as well as to the great compressive strength and stiffness of the concrete.

Installation Notes

Column grid spacing is generally 5-9.0m × 8-15m. Secondary beam spacing is 3m. But the cutting length of the steel decking sheet is 4.97-8.97m, which makes it difficult for the delivery and installation. It is especially hard when lifting the sheet vertically through secondary beams of arc-shaped constructions from the top down. The normal welding of secondary beams will be disturbed.

To control the cutting length within 3-6m is one way to make the lifting possible. One should adopt special soft slings for the lifting, and check if there is any torn or cut damage on the sling for each operation. Be careful with head when resting the floor deck on steel beams. The pavement operator should wear seat belts and fix the layer to security ropes while paving it.

Penetration welding is the right way of connection. Test welding on offcuts is necessary. Adjust the welding current if the test welding result is not good.

Since there is no parallel fromwork or vertical support at the bottom of the steel decking sheet, try not to pour concrete to any concentrated point. Use a plate-type vibrator for an even distribution.

Parameters

Name: Open-type Floor Deck Sheet

| Model | Thickness (mm) | Moment of inertia cm3/m | Section modulus cm3/m |

| YX70-200-600Coilwidth: 1000mm | 0.8 | 89.35 | 23.7 |

| 0.9 | 103.5 | 25.7 | |

| 1.0 | 118.6 | 31.6 | |

| 1.2 | 149.8 | 40.01 |

| Model | Thickness (mm) | Moment of inertia cm3/m | Section modulus cm3/m |

| YX75-200-600Coilwidth: 1000mm | 0.6 | 60.38 | 16.42 |

| 0.8 | 76.57 | 20.31 | |

| 1.0 | 100.64 | 27.37 | |

| 1.2 | 128.19 | 35.96 |

| Model | Thickness (mm) | Moment of inertia cm3/m | Section modulus cm3/m |

| YX75-293-880Coilwidth: 1219mm | 0.7 | 102.3 | 23.481 |

| 0.9 | 122.8 | 29.52 | |

| 1.2 | 164.4 | 40.464 | |

| 1.5 | 205.5 | 50.313 |

| Model | Thickness (mm) | Moment of inertia cm3/m | Section modulus cm3/m |

| YX76-344-688Coilwidth: 1000mm | 0.8 | 91.62 | 23.46 |

| 1.0 | 119.38 | 30.61 | |

| 1.2 | 142.01 | 38.98 | |

| 1.4 | 167.34 | 43.90 | |

| 1.5 | 178.70 | 46.80 |

| Model | Thickness (mm) | Moment of inertia cm3/m | Section modulus cm3/m |

| YX51-253-760Coilwidth: 1000mm | 0.8 | 53.80 | 19.30 |

| 1.0 | 67.30 | 24.20 | |

| 1.2 | 80.80 | 29.20 |

| Model | Thickness (mm) | Moment of inertia cm3/m | Section modulus cm3/m |

| YX51-240-720Coilwidth: 1000mm | 0.8 | 47.52 | 17.9 |

| 0.9 | 53.8 | 20.1 | |

| 1.0 | 58.1 | 22.9 | |

| 1.2 | 68.7 | 28.4 |

| Model | Thickness (mm) | Moment of inertia cm3/m | Section modulus cm3/m |

| YX51-304-914Coilwidth: 1170mm | 0.8 | 106.6 | 24.46 |

| 1.0 | 127.9 | 30.76 | |

| 1.2 | 171.3 | 42.15 | |

| 1.5 | 214.1 | 52.41 |

Name: Close Type Floor Decking Sheet

| Model | Thickness (mm) | Moment of inertia cm3/m | Section modulus cm3/m |

| YX65-185-555 | 0.8 | 53.95 | 25.614 |

| 1 | 67.44 | 32.018 | |

| 1.2 | 80.928 | 36.02 |

Name: Dovetail Type Steel Floor Sheet

| Model | Thickness (mm) | Moment of inertia cm3/m | Section modulus cm3/m |

| YX51-190-760Coilwidth: 1250mm | 0.8 | 54.803 | 14.42 |

| 1.0 | 68.504 | 18.02 | |

| 1.2 | 82.204 | 21.63 | |

| 1.5 | 102.756 | 27.04 |

| Model | Thickness (mm) | Moment of inertia cm3/m | Section modulus cm3/m |

| YX51-200-600Coilwidth: 1000mm | 0.8 | 54.803 | 14.42 |

| 1.0 | 68.504 | 18.02 | |

| 1.2 | 82.204 | 21.63 | |

| 1.5 | 102.756 | 27.04 |

Links:https://www.globefindpro.com/products/75728.html